Processing method for controlling microbes of dehydrated spices through combining irradiation of high-energy electron beams with hot-air drying

A high-energy electron beam and hot air drying technology, which is applied in the field of drying, storage and processing of agricultural products, can solve the problems of low quality and safety, large number of microorganisms in dehydrated spices, and lack of effective pretreatment methods for raw materials, so as to improve drying efficiency and overcome odor and quality deterioration phenomenon, the effect of protecting color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the method for the production of dehydrated chili dried by high-energy electron beam combined with hot air drying

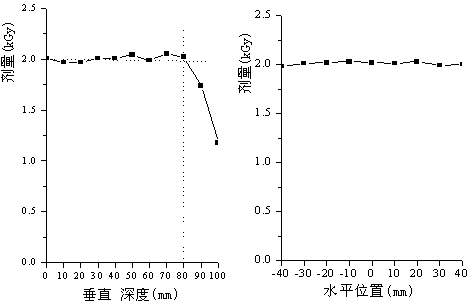

[0017] Pretreatment of fresh peppers, removal of inclusions and obvious rotten peppers in fresh raw materials, washing with tap water, removing foreign matter such as leaves attached to the surface, and then draining; put the peppers evenly in a metal tray, and spread the peppers on the tray The thickness is controlled to be no more than 8cm, followed by high-energy electron accelerator irradiation treatment. The irradiation technical parameters are the output energy of the electron beam 5MeV, the distance between the high-energy electron beam scanner and the product is 400mm, the scanning frequency is 420pps, and the scanning width is 600mm. The transmission speed of the irradiating tray under the scanner beam is 6.2m / min, and the electron beam irradiation dose is controlled at 2.0kGy. Peppers after electron beam irradiation were dried with ...

Embodiment 2

[0018] Embodiment 2: the method for the production of dehydrated black pepper of high-energy electron beam combined with hot air drying

[0019]Pretreatment of fresh black pepper, pick out the inclusions and obviously rotten black pepper in the fresh black pepper raw materials, wash with tap water, remove foreign matter such as leaves attached to the surface, and then drain; after pretreatment, the fresh black pepper is subjected to high-energy electronic processing. Beam irradiation treatment, put the black pepper evenly into the metal tray, and the black pepper is laid on the tray to control the thickness of about 5cm; after that, the high-energy electron accelerator irradiation treatment is carried out. The irradiation technical parameters are that the output energy of the electron beam is 10MeV, and the high-energy electron The distance between the beam scanner and the product is 450mm, the scanning frequency is 200pps, and the scanning width is 600 mm. The raw material tra...

Embodiment 3

[0020] Embodiment 3: the method for producing dehydrated Zanthoxylum bungeanum grains by high-energy electron beam combined with hot air drying

[0021] Pretreatment of fresh peppercorns, picking out the inclusions in the fresh peppercorns raw materials, washing them with tap water, removing foreign matter such as leaves attached to the surface, and then draining. After pretreatment, the fresh peppercorns are irradiated with high-energy electron beams, and the peppercorns are evenly placed in a metal tray. The thickness of the peppercorns laid in the tray does not exceed 7cm; The output energy of the beam is 8MeV, the distance between the high-energy electron beam scanner and the product is 520mm, the scanning frequency is 390pps, the scanning width is 600 mm, the transmission speed of the tray under the scanner is 5.6m / min, and the electron beam irradiation dose is controlled at 2.5 kGy. After electron beam irradiation, the Zanthoxylum bungeanum grains are dried in three sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com