Method for extracting food natural pigment from green plum pericarps

A technology of natural pigments and green plums, applied in the field of food additives, can solve the problems of odorous solvents, poor product quality, and solvent recovery, and achieve the effects of low cost, improved efficiency, and high food safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

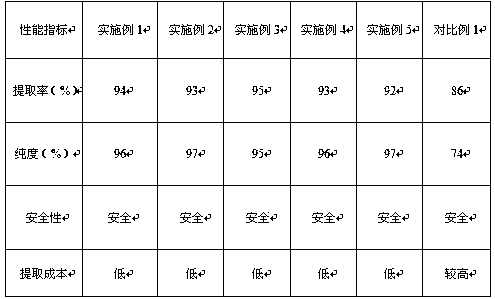

Examples

Embodiment 1

[0031] A method for extracting food natural pigment from green plum peel, characterized in that the extraction method is:

[0032] (1) Take fresh greengage, wash it with water, separate the pulp from the peel, add the peel to the salt water, disperse it homogeneously and heat it in microwave, and add salt continuously until excessive salt precipitation occurs, then filter to remove the excess Granular table salt and large-grained peel residues are obtained to obtain the filtrate;

[0033] (2) Prepare a compound enzyme with an enzyme activity of 10,000 u / g with endoglucanase and polygalacturonate lyase at a mass ratio of 1:2, and mix the filtrate obtained in step (1) with the compound enzyme In general, add 50 grams of compound enzyme per ton of filtrate, keep at 60°C, place in a dark and humid environment, and perform enzymatic hydrolysis for 3 days to obtain green plum peel enzymatic hydrolyzate; the compound enzyme is composed of cellulase and pectinase;

[0034] (3) Cool t...

Embodiment 2

[0037]A method for extracting food natural pigment from green plum peel, characterized in that the extraction method is:

[0038] (1) Take fresh greengage, wash it with water, separate the pulp from the peel, add the peel to the salt water, disperse it homogeneously and heat it in microwave, and add salt continuously until excessive salt precipitation occurs, then filter to remove the excess Granular table salt and large-grained peel residues are obtained to obtain the filtrate;

[0039] (2) Prepare a compound enzyme with an enzyme activity of 20,000 u / g with exoglucanase and pectin lyase at a mass ratio of 1:1, mix the filtrate obtained in step (1) with the compound enzyme, and mix each Add 150 grams of compound enzyme to 1 ton of filtrate, keep it at 60°C, place it in a dark and humid environment, and perform enzymatic hydrolysis for 3 days to obtain greengage peel enzymatic solution; the compound enzyme is composed of cellulase and pectinase;

[0040] (3) Cool the enzymoly...

Embodiment 3

[0043] A method for extracting food natural pigment from green plum peel, characterized in that the extraction method is:

[0044] (1) Take fresh greengage, wash it with water, separate the pulp from the peel, add the peel to the salt water, disperse it homogeneously and heat it in microwave, and add salt continuously until excessive salt precipitation occurs, then filter to remove the excess Granular table salt and large-grained peel residues are obtained to obtain the filtrate;

[0045] (2) Mix xylanase and polygalacturonase at a mass ratio of 2:1 to prepare a compound enzyme with an enzyme activity of 10,000 u / g, mix the filtrate obtained in step (1) with the compound enzyme, and mix each Add 200 grams of compound enzyme to 1 ton of filtrate, keep at 60°C, place in a dark and humid environment, and perform enzymatic hydrolysis for 4 days to obtain green plum peel enzymatic hydrolysis solution; the compound enzyme is composed of cellulase and pectinase;

[0046] (3) Cool th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com