Combined drying method for improving dehydration efficiency of maize

A combined drying and corn technology, which is applied in the storage and processing of grain and the production of dehydrated grain, can solve the problems of loss of heat-sensitive nutrients, severe deformation of tissue structure, and high temperature of drying medium, so as to shorten drying time, lower drying temperature, overcome The effect of a large crack rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

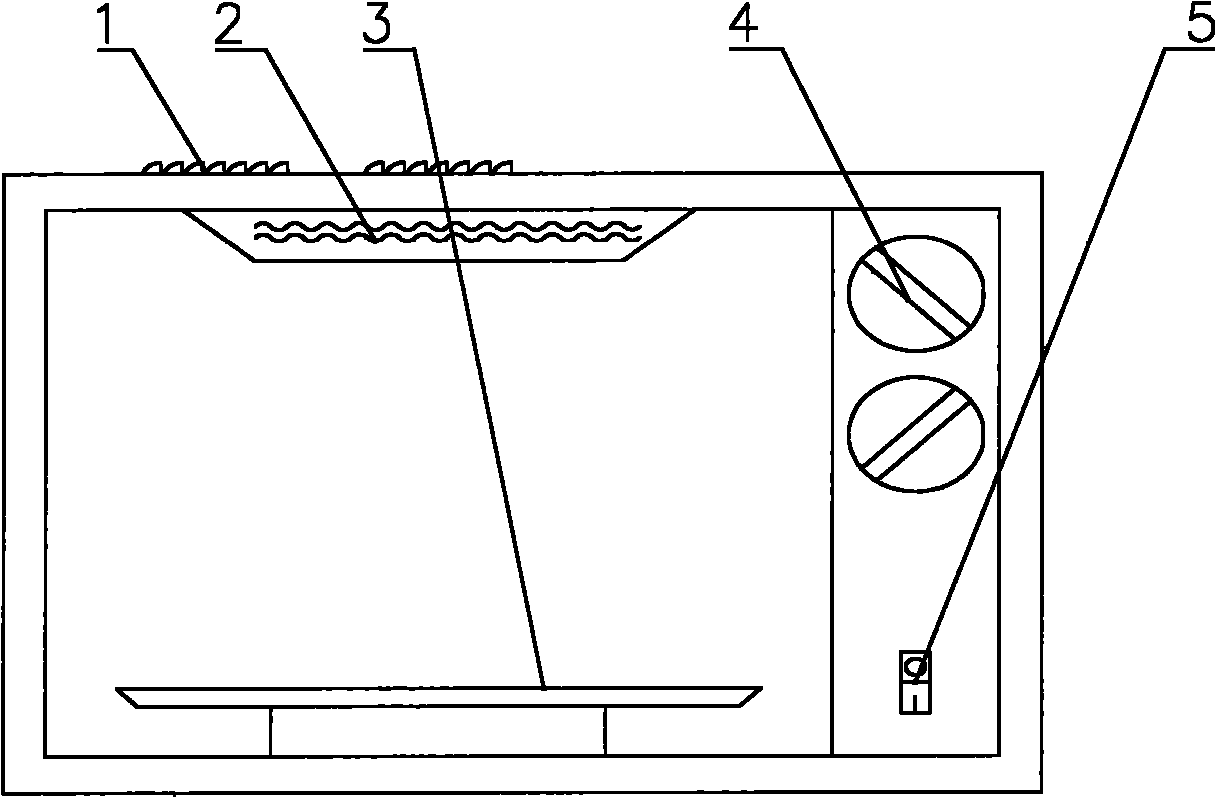

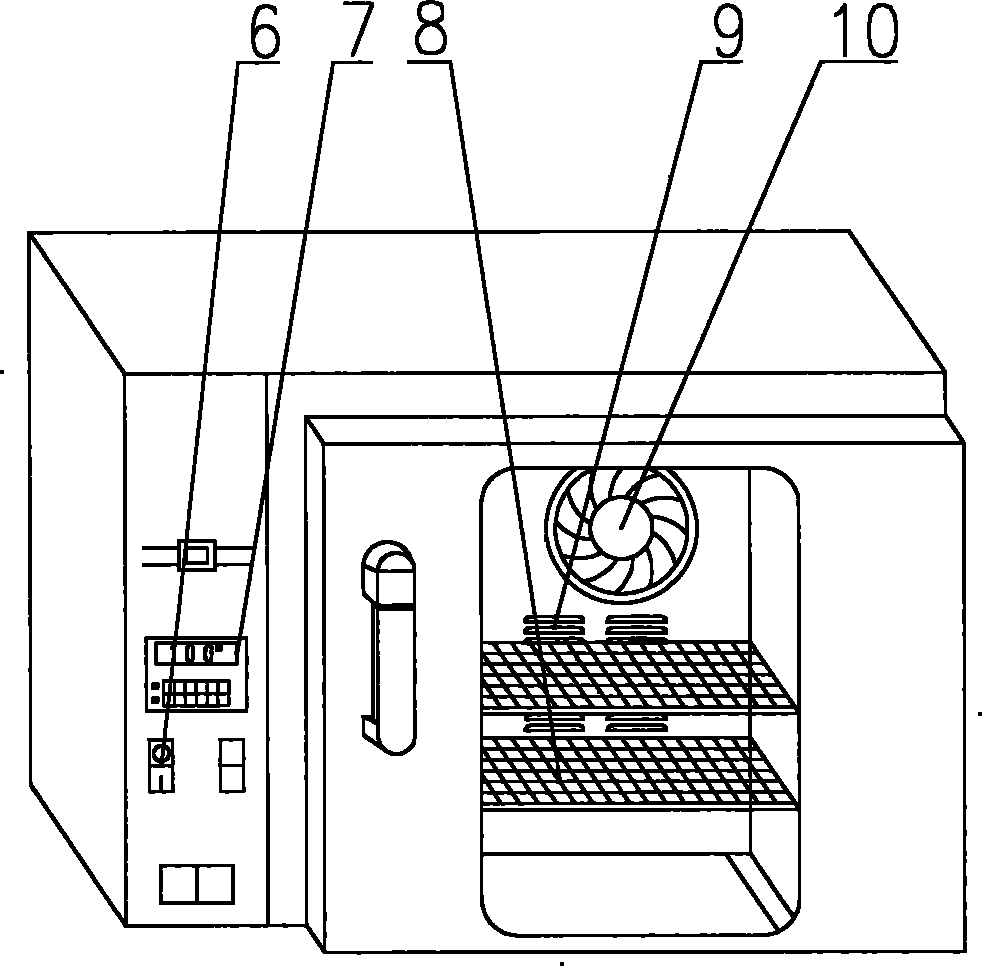

[0026] The specific content and implementation of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0027] The invention combines hot air drying and microwave drying (AMVD), and determines the combined drying process by inspecting the degree of denaturation of northeast corn in the dehydration stage through sensory index observation and physical and chemical indexes.

[0028] AMVD is to divide the entire drying process into two stages: first, the sample is dried with hot air to a certain moisture content, and then the sample is then microwave-dried to the final product. The specific process route is as follows:

[0029] Raw material selection → hot air drying to moisture conversion point → microwave drying to final moisture content → selection → impurity removal → packaging → storage

[0030] The present invention adopts a stage-by-stage joint drying method to improve the cost performance of dehydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com