A kind of preparation method of gravel-carrying filter pipe

A technology of water filter pipes and water pipes, which is applied in the field of water filter pipes, can solve the problems of poor effect of suction filtration, impact on strength, high cost, etc., and achieve the effects of improved efficiency, good sealing, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

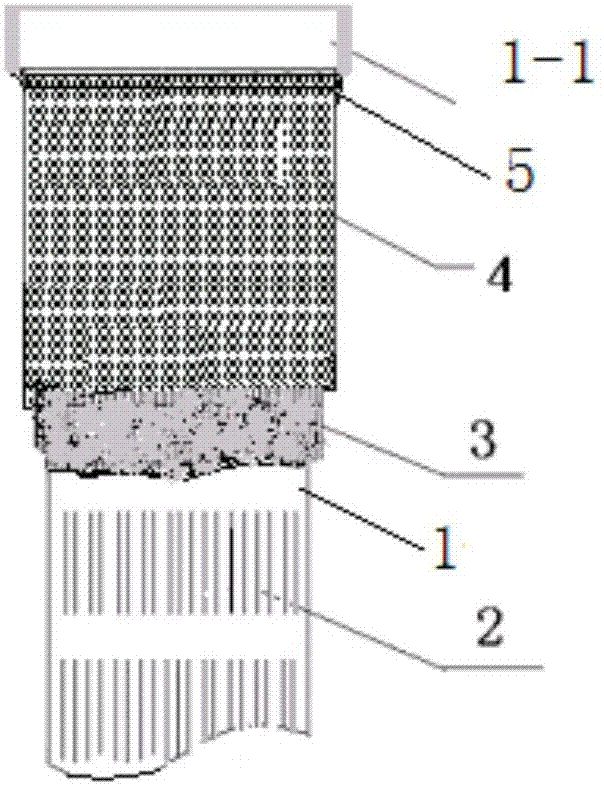

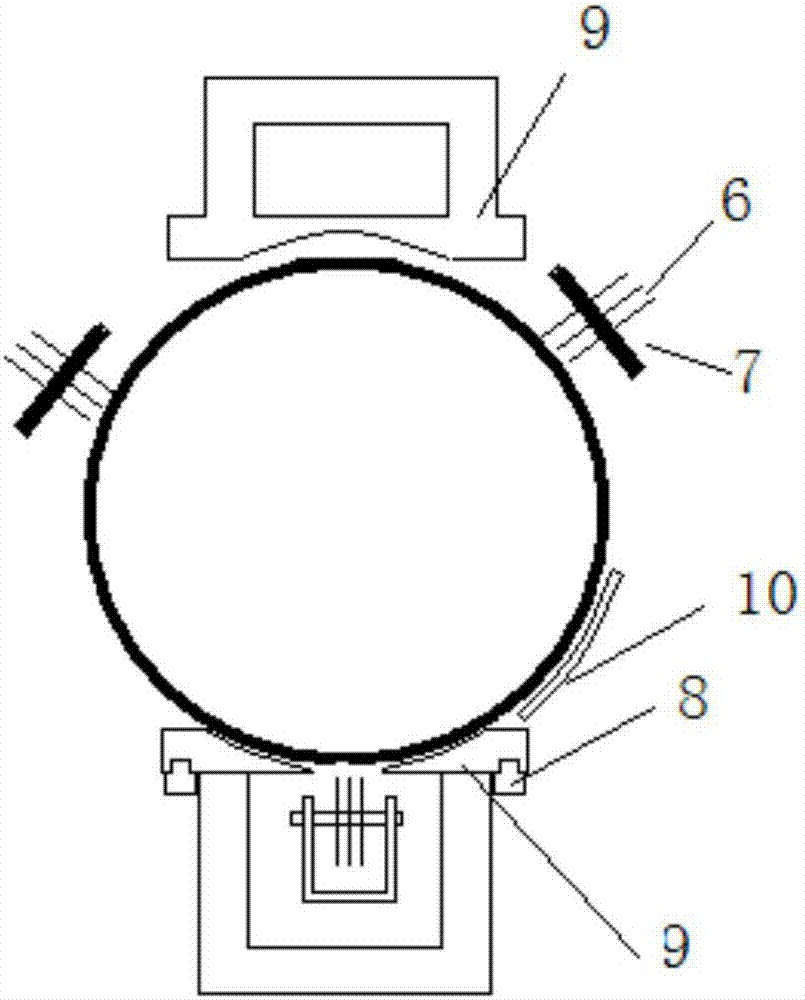

[0017] combine figure 1 and 2 , to further describe the present invention:

[0018] The present invention is successively made up of water pipe 1, slit 2, filter material 3, filter screen 4, fixed bracket 5 from inside to outside.

[0019] Gravel-carrying water pipes, including water pipes made of polymer materials, are evenly cut on the pipe wall in the axial direction of the water pipe, that is, in the length direction. Make a cut. The two ends of the water pipe are connected with thread buckle ring structure. The total length of the slit of each water pipe is 1500-2000cm; the outside of the slit of the water pipe is covered with a filter screen, and a uniform granular filter material (or powder filter material) is provided between the filter screen and the wall of the water pipe. The upper hoop has at least two two-layer ring-shaped fixing brackets, in which the covering filter screen is fixed between the two layers of fixing brackets, and the gap formed by the inner fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com