Equipment for adsorbing heavy metal elements

A technology for adsorbing heavy metals and elements, applied in the direction of adsorption of water/sewage treatment, water/sewage multi-stage treatment, water pollutants, etc., can solve problems such as complex structure, waste of resources, heavy metal elements cannot be collected by heavy metal elements, etc., and achieve treatment efficiency High, resource-saving, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

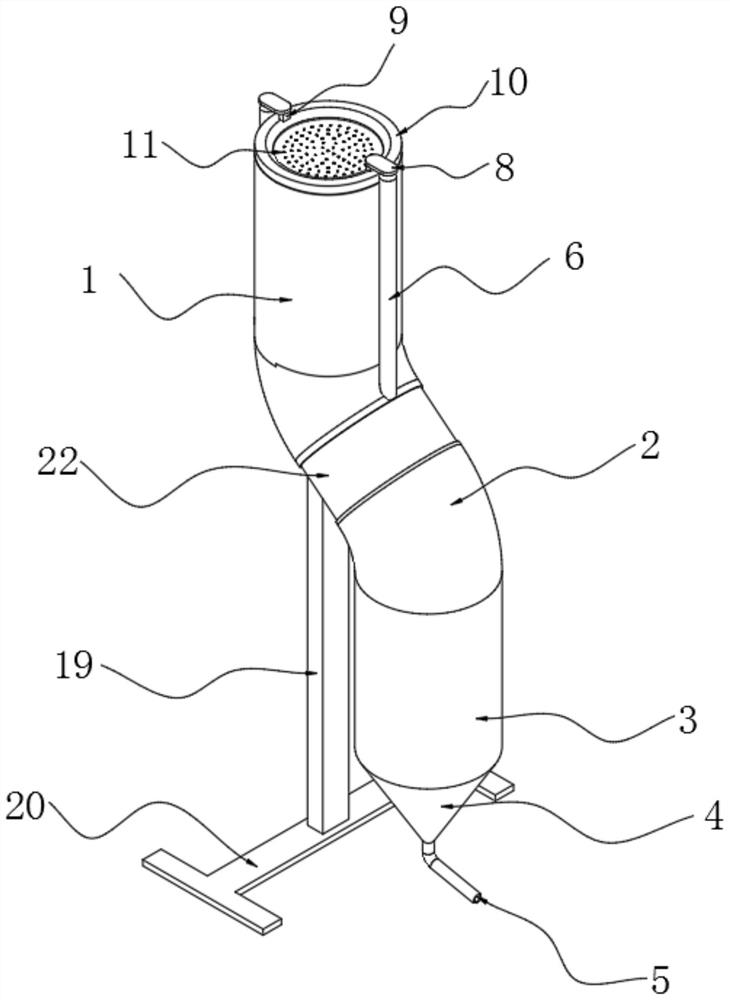

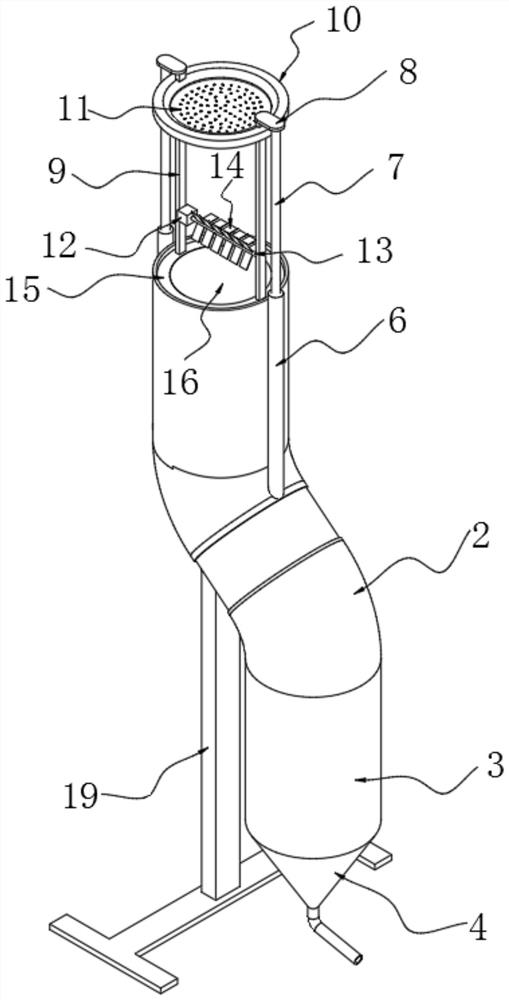

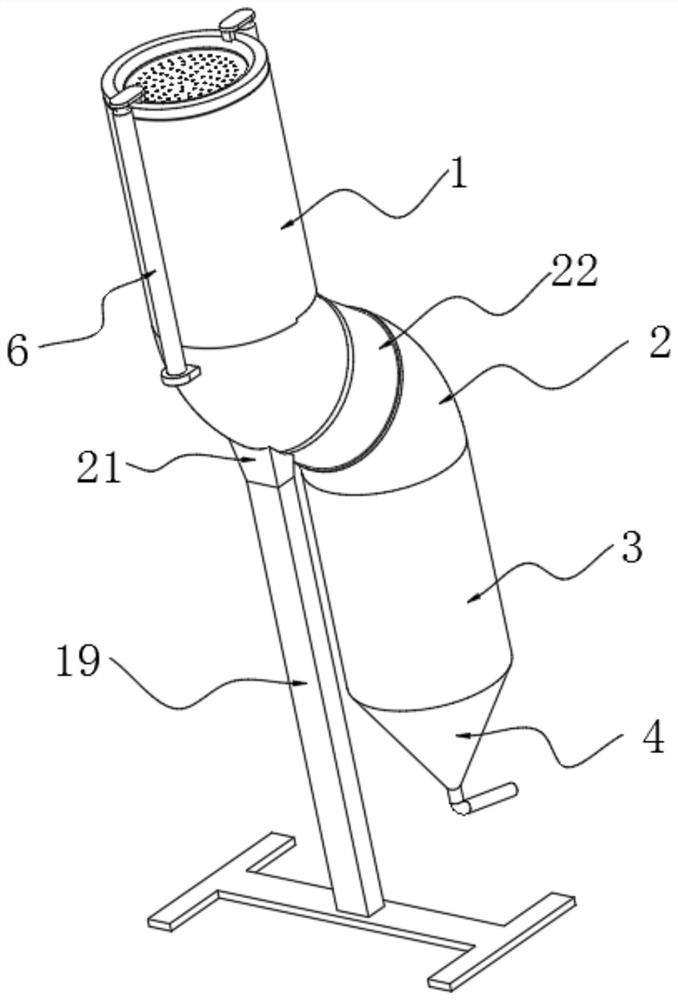

[0028] see figure 1 - Figure 5 , the present invention provides the following technical solutions: a kind of equipment for adsorbing heavy metal elements includes a processing channel, the processing channel includes a first processing channel 1, an arc-shaped processing channel 2, a second processing channel 3 and a conical connecting pipe 4, the first processing channel 1. The arc-shaped processing channel 2, the second processing channel 3 and the conical connecting pipe 4 are sequentially connected from top to bottom. The first processing channel 1 is provided with a recyclable adsorption mechanism, which includes two electric telescopic rods 6 , two electric telescopic rods 6 are connected to the circumferential surface of the first processing channel 1, extension ends 7 are arranged inside the two electric telescopic rods 6, and connection plates 8 are fixed on the upper ends of the two extension ends 7, and the two connection plates The bottoms of 8 are fixed with con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com