Connecting device for rotors and indexing monitoring equipment for machining wheel grooves of rotors of steam turbines

A technology for steam turbine rotors and monitoring equipment, which is applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

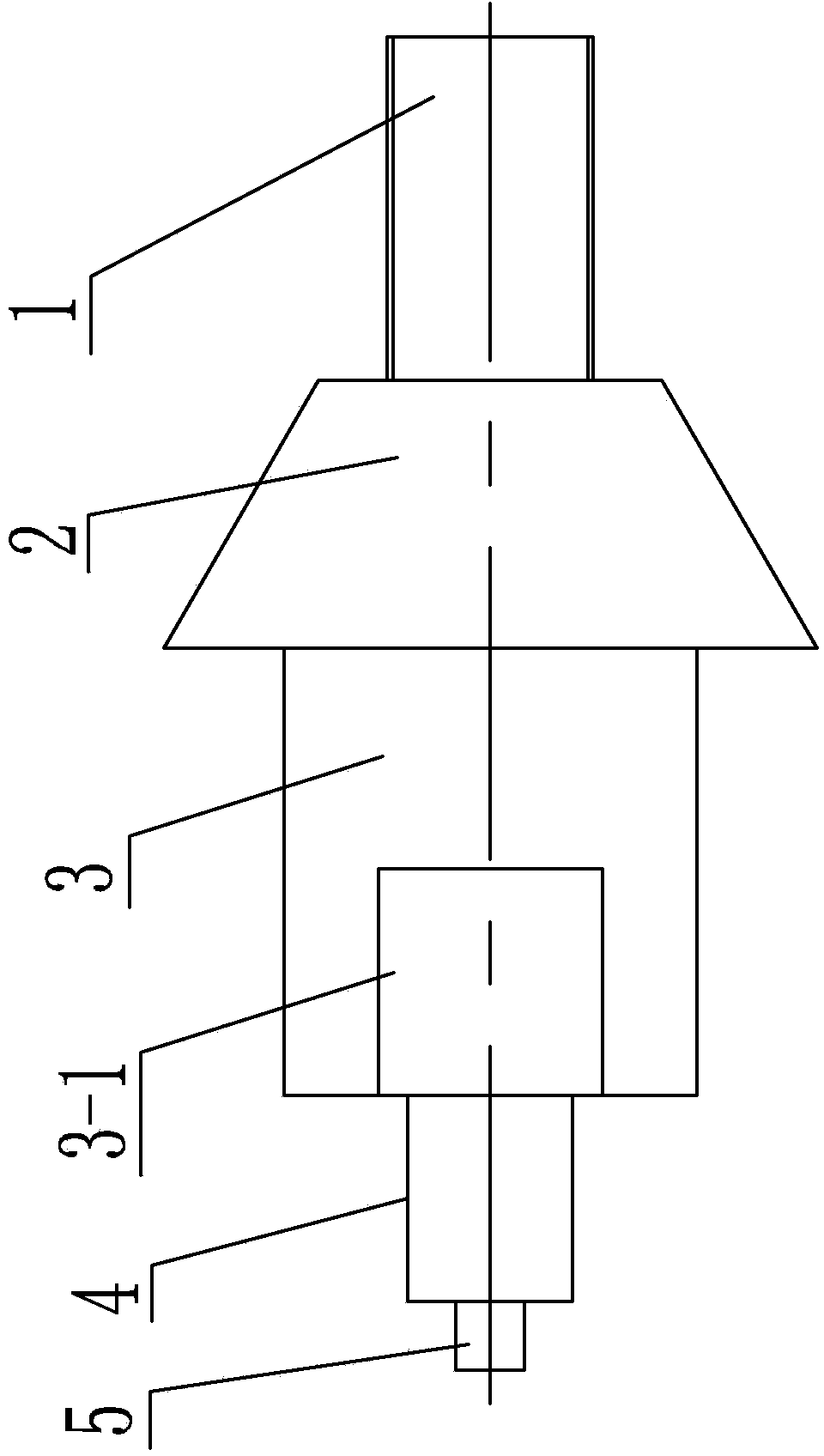

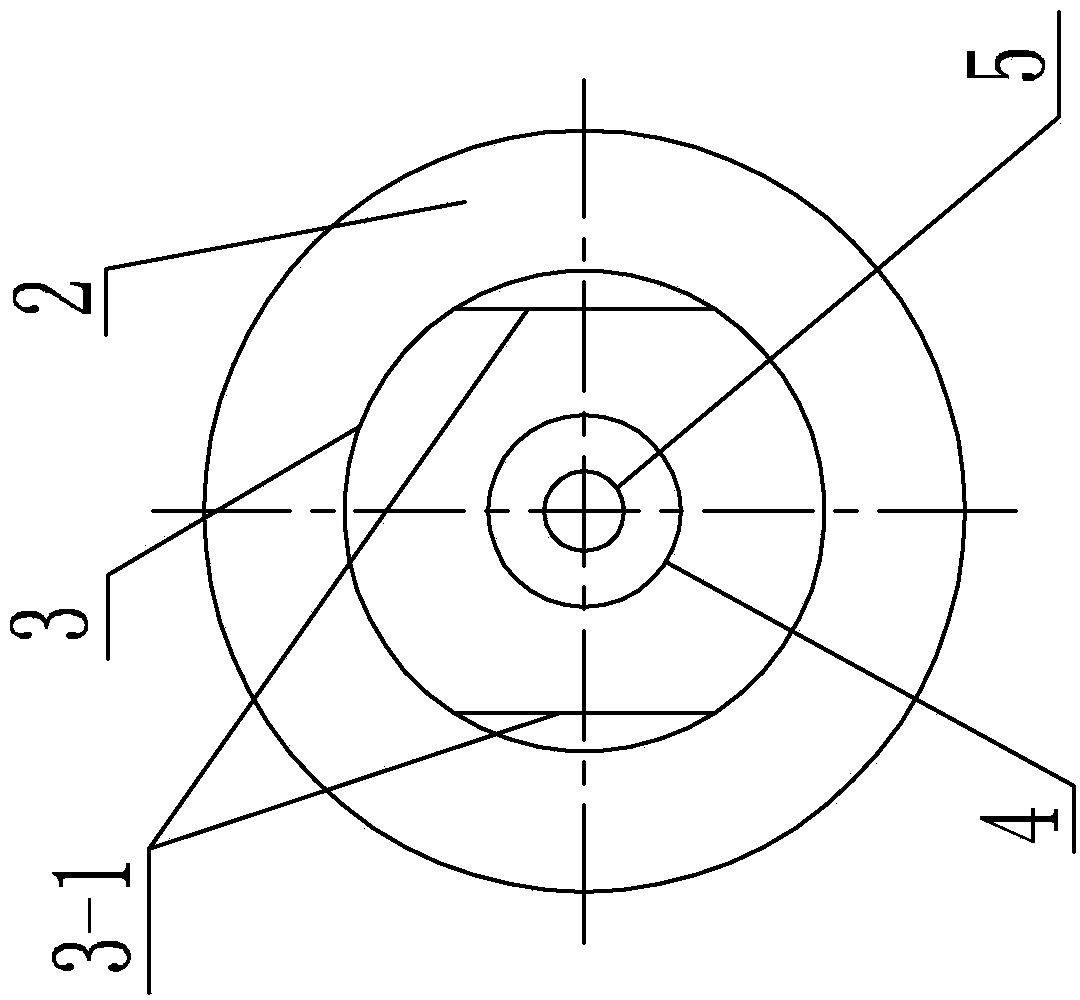

[0009] Specific implementation mode one: as Figure 1~2 As shown, the connection device between the indexing monitoring equipment for machining the wheel groove of the steam turbine rotor and the rotor in this embodiment includes a first cylindrical section 1, a circular platform section 2, a second cylindrical section 3, a fourth cylindrical section 4 and a fifth cylindrical section 5 , the first cylindrical section 1, the circular frustum section 2, the second cylindrical section 3, the fourth cylindrical section 4 and the fifth cylindrical section 5 are fixed together in sequence along the axial direction, one end of the first cylindrical section 1 and the small One end of the second cylindrical section 3 is affixed to the large end of the round table section 2, the first cylindrical section 1 is processed with external threads along the length direction, and the second cylindrical section 3 is symmetrically processed with two rectangular platforms 3- 1.

[0010] The exter...

specific Embodiment approach 2

[0011] Specific implementation mode two: as figure 1 As shown, the rectangular platform 3 - 1 of this embodiment is located on the side close to the fourth cylinder segment 4 . With such a design, the first cylindrical section 1 can be fastened to the top hole of the rotor with a wrench. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: as figure 1 As shown, the outer diameters of the second cylindrical section 3 , the fourth cylindrical section 4 and the fifth cylindrical section 5 in this embodiment are set from large to small. In such a design, the fifth cylindrical section 5 is used for positioning with the pin hole of the indexing monitoring equipment, the fourth cylindrical section 4 is fixedly connected with the indexing monitoring equipment through the jackscrew, and the second cylindrical section 3 can realize the first cylindrical section 3 through a wrench. The segment is fastened to the rotor. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com