Preparation method of gas sensor for hydrocarbon gas detection

A gas sensor, hydrocarbon gas technology, applied in measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of high processing cost, high operating temperature, complex synthesis process, etc., and achieve low processing cost and sensitivity. High, easy to synthesize effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

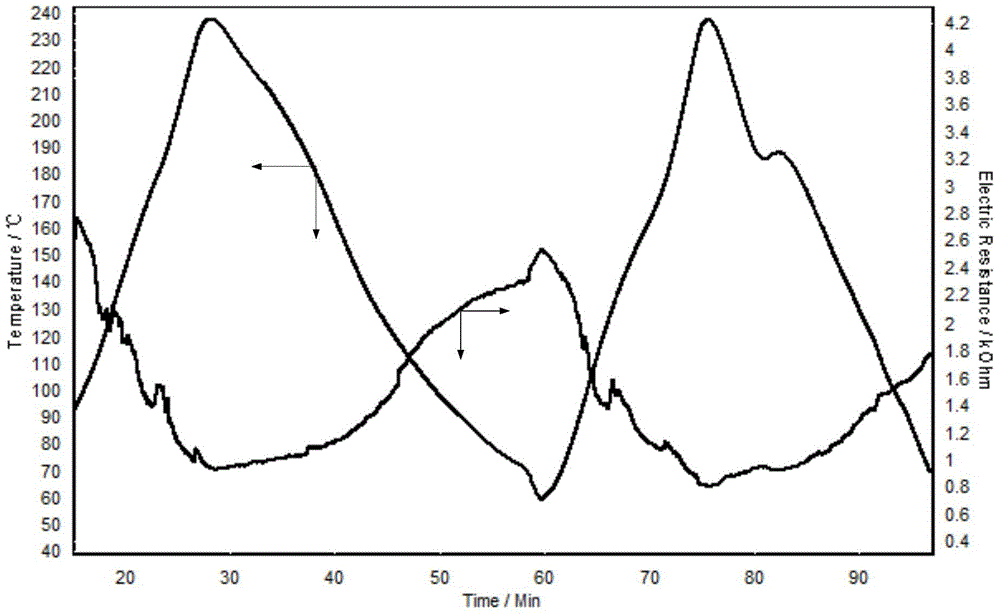

Image

Examples

Embodiment 1

[0021] The invention provides a method for preparing a tin oxide thin film gas sensor for hydrocarbon gas detection, comprising the following steps:

[0022] (1) Pretreatment of the substrate: treat the ceramic substrate with concentrated hydrochloric acid for 5 minutes, then treat it with concentrated ammonia water for 15 minutes, and dry it in an oven at 100°C.

[0023] (2) Preparation of tin dioxide: at 50°C, add 10 grams of SnCl to 50 mL of absolute ethanol 2 2H 2 O, make it dissolve into a transparent solution with sufficient stirring, the concentration is 0.25kg / L.

[0024] (3) Preparation of tin dioxide thin film: under the condition of constant temperature water bath at 72°C, put the treated substrate into the solution to coat the film, and ensure that the thickness of the film on the substrate is uniform during the coating process, and let it dry naturally in the air , repeated 5 times, and placed in an oven at 107°C for 1 hour. The weight ratio of the pretreated s...

Embodiment 2

[0035] The invention provides a method for preparing a tin oxide thin film gas sensor for hydrocarbon gas detection, comprising the following steps:

[0036] (1) Pretreatment of the substrate: treat the ceramic substrate with concentrated hydrochloric acid for 3 minutes, then treat it with concentrated ammonia water for 10 minutes, and dry it in an oven at 80°C.

[0037] (2) Preparation of tin dioxide: at 45°C, add 20 grams of SnCl to 50 mL of absolute ethanol 2 2H 2 O, make it dissolve into a transparent solution with sufficient stirring, the concentration is 0.5kg / L.

[0038] (3) Preparation of tin dioxide film: under the condition of 65°C constant temperature water bath, put the treated substrate into the solution to coat the film, and ensure that the thickness of the film on the substrate is uniform during the coating process, and let it dry naturally in the air , repeated 2 times, and placed in an oven at 90°C for 2 hours. The weight ratio of the pretreated substrate t...

Embodiment 3

[0041] The invention provides a method for preparing a tin oxide thin film gas sensor for hydrocarbon gas detection, comprising the following steps:

[0042] (1) Pretreatment of the substrate: treat the ceramic substrate with concentrated hydrochloric acid for 8 minutes, then treat it with concentrated ammonia water for 20 minutes, and dry it in an oven at 120°C.

[0043] (2) Preparation of tin dioxide: at 43°C, add 10 grams of SnCl to 100 mL of absolute ethanol 2 2H 2 O, under full stirring to dissolve into a transparent solution with a concentration of 0.13kg / L.

[0044] (3) Preparation of tin dioxide film: under the condition of constant temperature water bath at 75°C, put the treated substrate into the solution to coat the film, and ensure that the thickness of the film on the substrate is uniform during the coating process, and let it dry naturally in the air , repeated 5 times, and placed in an oven at 120° C. to continue drying for 0.5 hours. The weight ratio of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com