Glass fiber and processing technology thereof

A glass fiber and processing technology, applied in the field of glass fiber and its processing technology, can solve the problems of poor acid resistance of glass fiber, affecting production efficiency, and high molding temperature, achieving low processing cost, improving production efficiency, and forming low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

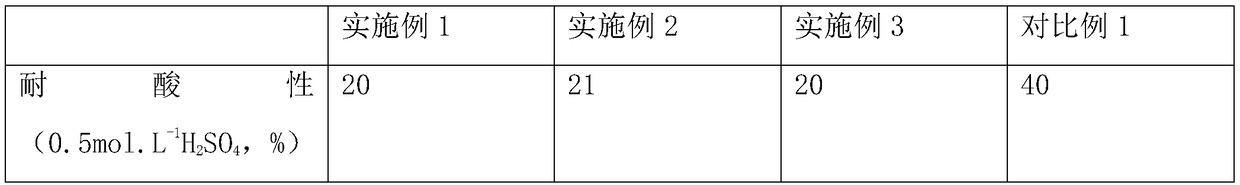

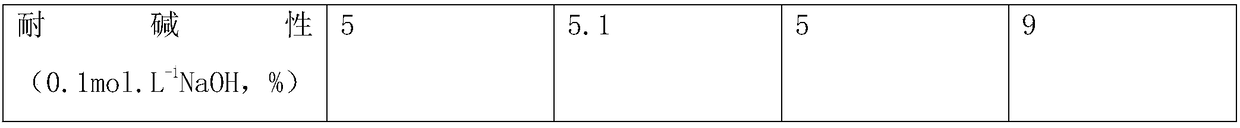

Examples

Embodiment 1

[0025] A glass fiber, consisting of the following raw materials in parts by weight: SiO 2 30 parts, Al 2 o 3 6 parts, CaF 2 1 part, ZrO 2 10 copies, Ln 2 o 3 11 parts, TiO 2 4 copies, H 2 O 60 parts, H 3 BO 3 50 servings.

[0026] A processing technology for the above-mentioned glass fiber, comprising the following steps: (1) SiO2, Al2O3, CaF2, ZrO2, Ln2O3, TiO2, H2O are uniformly ball-milled and mixed to obtain a mixture A in the above parts by weight; (2) the mixture A is passed through a mist (3) Dry the powder B and carry out isostatic pressing in a cold isostatic press at 300MPa to obtain a block C; (4) place the block C at 1300 Melting at a temperature of ℃ to obtain molten glass; (5) putting the above-mentioned obtained molten glass into a wire drawing machine for wire drawing, and the rotating speed of the wire drawing machine is 1200 rpm to obtain the first product of glass fiber; (6) putting the first product of glass fiber into Enter the H of above-...

Embodiment 2

[0029] A glass fiber, consisting of the following raw materials in parts by weight: 50 parts of SiO2, 10 parts of Al2O3, 4 parts of CaF2, 14 parts of ZrO2, 16 parts of Ln2O3, 6 parts of TiO2, 70 parts of H2O, H 3 BO 3 70 servings.

[0030]A processing technology for the above-mentioned glass fiber, comprising the following steps: (1) SiO2, Al2O3, CaF2, ZrO2, Ln2O3, TiO2, H2O are uniformly ball-milled and mixed to obtain a mixture A in the above parts by weight; (2) the mixture A is passed through a mist (3) Dry the powder B and carry out isostatic pressing in a cold isostatic press at 500MPa to obtain block C; (4) place block C at 1400 Melting at a temperature of ℃ to obtain molten glass; (5) putting the above-mentioned obtained molten glass into a wire drawing machine for wire drawing, and the rotating speed of the wire drawing machine is 1600 rpm to obtain the first product of glass fiber; (6) putting the first product of glass fiber into Enter the H of above-mentioned pa...

Embodiment 3

[0033] A glass fiber consisting of the following raw materials in parts by weight: 40 parts of SiO2, 8 parts of Al2O3, 2 parts of CaF2, 12 parts of ZrO2, 13 parts of Ln2O3, 5 parts of TiO2, 65 parts of H2O, H 3 BO 3 60 servings.

[0034] A processing technology for the above-mentioned glass fiber, comprising the following steps: (1) SiO2, Al2O3, CaF2, ZrO2, Ln2O3, TiO2, H2O are uniformly ball-milled and mixed to obtain a mixture A in the above parts by weight; (2) the mixture A is passed through a mist (3) Dry powder B and perform isostatic pressing in a cold isostatic press at 400MPa to obtain block C; (4) Place block C at 1350 Melting at a temperature of ℃ to obtain molten glass; (5) putting the above-mentioned obtained molten glass into a wire drawing machine for wire drawing, and the rotating speed of the wire drawing machine is 1400 rpm to obtain the first product of glass fiber; (6) putting the first product of glass fiber into Enter the H of above-mentioned parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com