A kind of roll forming method of elongated shaped bar

A profiled and rolling technology, applied in the field of profile processing, can solve the problems of low production efficiency, high processing cost, poor product quality, etc., and achieve the effect of high production efficiency, low processing cost and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

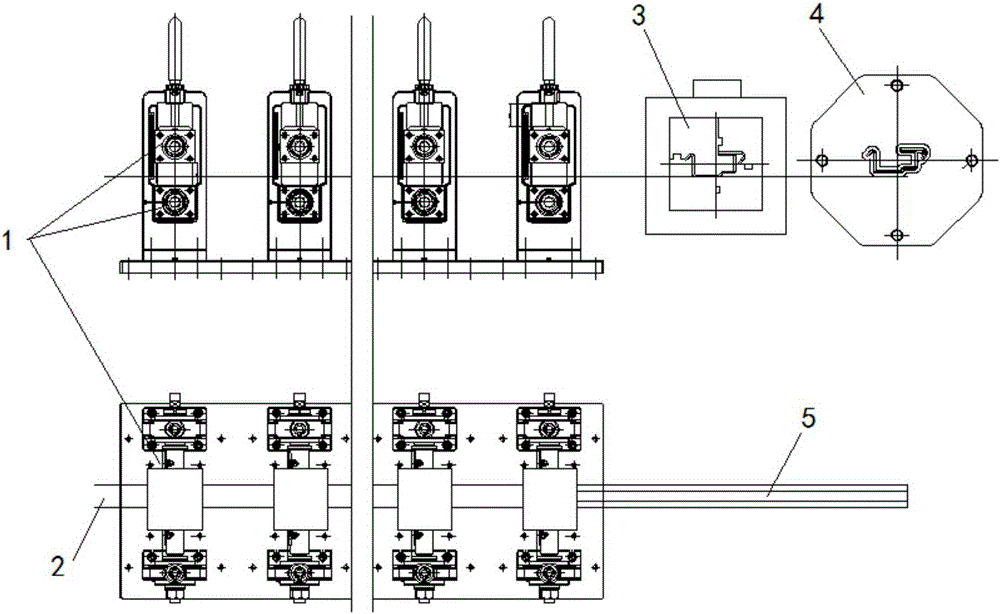

[0053] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

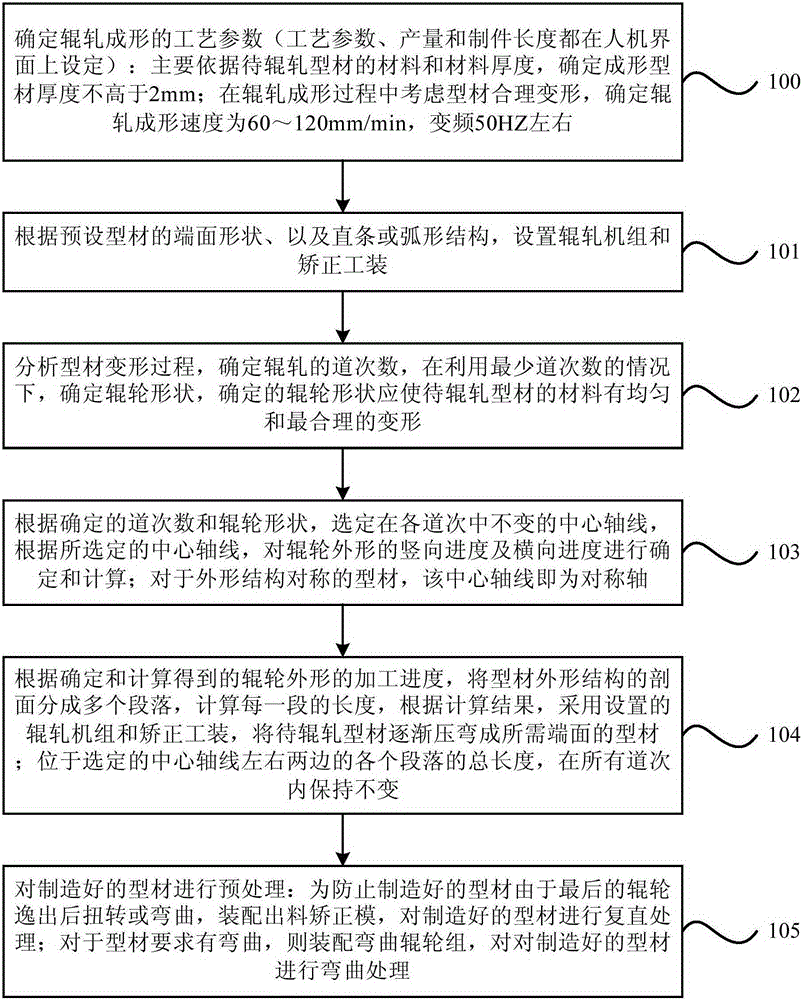

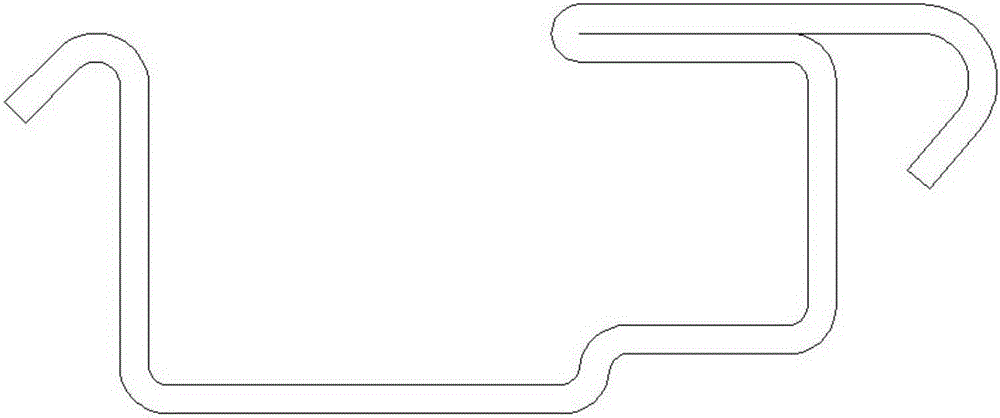

[0054] According to an embodiment of the present invention, such as Figure 1-Figure 6b As shown, a method for roll forming of long profiled bars is provided.

[0055] The roll forming method for elongated profiled materials in this embodiment adopts the roll forming process, specifically: rolling metal flat strips such as coils and profiles through sequentially configured multi-pass forming rolls. When the flat metal strip is fed forward, the flat metal strip is continuously bent transversely to make a preset specific end-face profile processing method. Roll forming is a material-saving, energy-saving and efficient sheet metal forming process and new technology for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com