PP-PA alloy and preparation method thereof

A PP-PA and alloy technology, applied in the field of organic polymer compounds, can solve problems such as market promotion restrictions and poor mechanical strength, and achieve the effects of good toughness, low processing cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

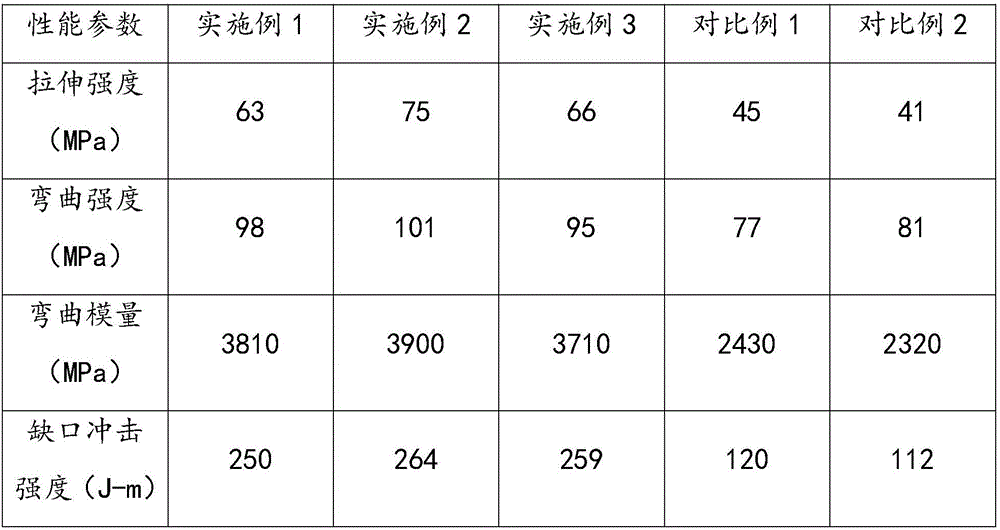

Examples

Embodiment 1

[0024] 40 parts of PP, 30 parts of PA, 5 parts of red mud, 1 part of wollastonite, 1 part of glass microspheres, 1 part of hydrotalcite, 1 part of silane coupling agent, and 1 part of polyolefin elastomer grafted with maleic anhydride , 5 parts of graphite, and 1 part of graft compound containing acrylate functional groups are uniformly mixed, extruded through a twin-screw extruder to obtain a PP-PA alloy; the red mud, wollastonite, glass microspheres, hydrotalcite, graphite It is 1500 mesh, wherein the speed of the twin-screw extruder is controlled at 200rpm, the temperature of the first zone of the twin-screw extruder is 180°C, the temperature of the second zone is 200°C, the temperature of the third zone is 210°C, and the temperature of the fourth zone is 260°C. The temperature of the fifth zone is 270°C, the temperature of the sixth zone is 280°C, the temperature of the seventh zone is 270°C, the temperature of the eighth zone is 250°C, the temperature of the ninth zone is ...

Embodiment 2

[0026] 45 parts of PP, 35 parts of PA, 8 parts of red mud, 3 parts of wollastonite, 3 parts of glass microspheres, 2 parts of hydrotalcite, 3 parts of silane coupling agent, and 3 parts of polyolefin elastomer grafted maleic anhydride compound , 8 parts of graphite, and 2 parts of copolymers containing acrylate functional group compounds are uniformly mixed, and extruded through a twin-screw extruder to obtain a PP-PA alloy; the red mud, wollastonite, glass beads, hydrotalcite, graphite The temperature of the twin-screw extruder is 1700 mesh, the speed of the twin-screw extruder is controlled at 250rpm, the temperature of the first zone of the twin-screw extruder is 190°C, the temperature of the second zone is 210°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 280°C, and the temperature of the fifth zone The temperature is 290°C, the temperature in the sixth zone is 300°C, the temperature in the seventh zone is 280°C, the temperature in the...

Embodiment 3

[0028] 50 parts of PP, 40 parts of PA, 10 parts of red mud, 5 parts of wollastonite, 5 parts of glass beads, 3 parts of hydrotalcite, 5 parts of silane coupling agent, and 5 parts of polyolefin elastomer grafted with maleic anhydride , 10 parts of graphite, and 3 parts of copolymers containing acrylate functional group compounds are evenly mixed, and extruded through a twin-screw extruder to obtain a PP-PA alloy; the red mud, wollastonite, glass microspheres, hydrotalcite, graphite It is 1800 mesh, wherein the speed of the twin-screw extruder is controlled at 300rpm, the temperature of the first zone of the twin-screw extruder is 200°C, the temperature of the second zone is 220°C, the temperature of the third zone is 240°C, and the temperature of the fourth zone is 300°C. The temperature of the fifth zone is 300°C, the temperature of the sixth zone is 300°C, the temperature of the seventh zone is 300°C, the temperature of the eighth zone is 260°C, the temperature of the ninth z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com