Integrated device and method for producing handrails

A technology of a railing and a soot blowing device, which is applied to a device for coating liquid on a surface, a spray device, a fence, etc., can solve the problems of physical injury of the operator, difficulty in obtaining the painting effect, prolonging the painting time, etc., to reduce labor intensity, The effect of improving processing efficiency and processing quality and reducing the number of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

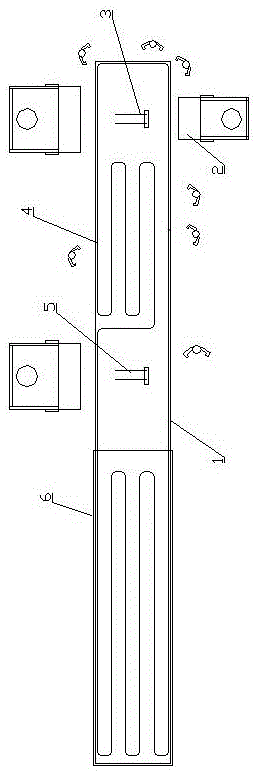

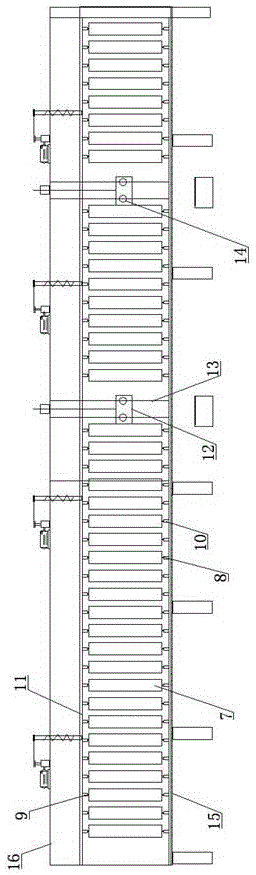

[0026] Embodiment 1, with reference to figure 1 and figure 2 , an integrated device for producing railings, including a frame 16, a railing conveying guide rail 1 is arranged on the frame 16, one end of the railing conveying rail 1 is a feed end, and the other end is a discharge end, from the feed end to the discharge end One side of the railing conveying guide rail 1 at the material end is provided with an automatic soot blowing device 2, an automatic color repairing device 3, a drying device 4, a surface paint spraying device 5 and a drying bin 6, and the automatic soot blowing device 2, the automatic repairing device The railing conveying rail 1 opposite to the coloring device 3 and the spraying paint device 5 is provided with a rotary drive mechanism that makes the railing 7 rotate; the railing conveying rail 1 includes an upper conveying chain 11 and a lower conveying chain 15 arranged in parallel, Between the conveying chain 11 and the lower conveying chain 15, there i...

Embodiment 2

[0027] Embodiment 2, in the integrated device for producing railings described in Embodiment 1: the described rotary drive mechanism includes a rotating wheel located below the lower conveying chain 15, the axle of the rotating wheel is collinear with the axis of the lower thimble 8, and the rotating wheel Installed on the lower thimble 8, the frame opposite to the automatic soot blowing device 2, the automatic color correction device 3 and the paint spraying device 5 is provided with a transmission wheel meshed with the rotating wheel, and the frame is provided with The motor that drives the transmission wheel to roll facilitates the circumferential processing of the railing.

Embodiment 3

[0028] Embodiment 3, in the integrated device for producing railings described in Embodiment 1: in the integrated device for producing railings: both the first lifting mechanism and the second lifting mechanism include vertically arranged guide columns 13 and the elevating frame 12 that is contained on the guide column 13, described spray gun 14 or soot blowing nozzle are contained on the elevating frame 12, and the frame is provided with the driving oil cylinder that drives elevating frame lifting, facilitates the vertical processing of railing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com