Air-screen cleaning device for self-propelled longitudinal dual-axial millet combine harvester

A technology of combine harvester and cleaning device, applied in application, agricultural machinery and implements, threshing equipment, etc., can solve the problems of tangling and agglomeration, entrainment and discharge of grains, and silting and blocking of cleaning screen area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

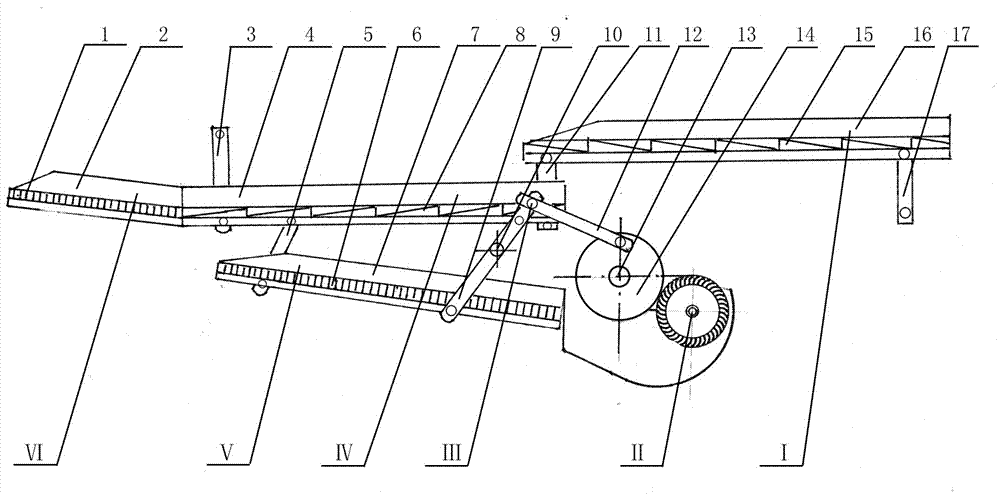

[0028] as attached figure 1 As shown in the figure, the self-propelled longitudinal double axial flow millet combine harvester used in the wind screen cleaning device researched and designed by this patent includes a stepped shaking plate (I), a stepped punching type upper cleaning screen (IV), and a braided lower screen. Cleaning screen (Ⅴ), braided tail screen (Ⅵ), cross-flow fan (Ⅱ), crank swing arm drive mechanism (Ⅲ) and other main functional components, the overall air screen cleaning device is installed and arranged in the form of longitudinal correspondence. In the inner cavity of the machine body below the longitudinal double axial flow threshing separation device provided in the main machine, the front end is hinged to the shaking plate support seat provided on the inner side of the front part of the left and right side walls of the main machine respectively through the left and right shaking plate swing arms (17). The rear end is hinged to the upper screen hanger pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com