Clean production method for continuously synthesizing hydantoin

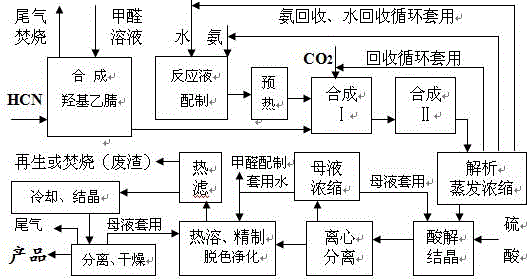

A production method and chemical synthesis technology, which are applied in the field of continuous chemical synthesis of hydantoin clean production, can solve the problems of product quality and device operation stability, automation control production difficulties, incomplete solution of environmental protection problems, etc., and achieve the suppression of harmful impurities. Generate, easy to automate control, improve the effect of investment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

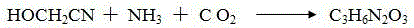

[0037] Example 1: 37% formaldehyde solution was used to absorb purified hydrocyanic acid gas to obtain 500 g / l aqueous solution of hydroxyacetonitrile; ammonia, carbon dioxide, and water were prepared in a molar ratio of 1:1:10 to prepare a carbon dioxide ammonia water reaction system.

[0038] Continuously feed the above carbon dioxide and ammonia water system into the preheater with a pressure metering pump at a feed rate of 4T / hour, preheat the material temperature to 90°C, and inject the material into the first part of the combined continuous reactor: the volume is 200L A tube test reactor with an inner diameter of 65 mm and a tube length of about 60 meters. The material enters from the inlet end; at about 1.0 meters from the material inlet end, another plunger metering pump is used to feed the hydroxyacetonitrile aqueous solution at a rate of 400 kg / hour. Feed speed Continuous feed is mixed and reacted with the preheated carbon dioxide and ammonia water reaction system. Th...

Embodiment 2

[0039] Example 2: Absorb purified hydrocyanic acid gas with 37% formaldehyde solution to prepare a 500 g / l aqueous solution of hydroxyacetonitrile; ammonia, carbon dioxide, and water are prepared in a molar ratio of 1:1:10 to prepare a carbon dioxide ammonia water reaction system.

[0040] The above carbon dioxide and ammonia water system is continuously fed into the preheater with a pressure metering pump at a feed rate of 2T / hour, the temperature of the preheated material is 85°C, and the material is injected into the first part of the combined continuous reactor: the volume is 200L The tube test reactor, the inner diameter of the tube is 65 mm, the tube length is about 60 meters, and the material enters from the inlet end; at 1.0 meters from the material inlet end, a plunger metering pump is used to feed the hydroxyacetonitrile aqueous solution at a rate of 200 kg / hour The speed continuous feeding is mixed and reacted with the preheated carbon dioxide and ammonia water react...

Embodiment 3

[0041] Example 3: 37% formaldehyde solution was used to absorb purified hydrocyanic acid gas to obtain 500 g / l aqueous solution of hydroxyacetonitrile; ammonia, carbon dioxide, and water were prepared in a molar ratio of 1:1:10 to prepare a carbon dioxide ammonia water reaction system.

[0042] The above carbon dioxide and ammonia water system is continuously fed into the preheater with a pressure metering pump at a feed rate of 4T / hour, the temperature of the preheated material is 80°C, and the material is injected into the first part of the combined continuous reactor: the volume is 200L The tube test reactor, the inner diameter of the tube is 65 mm, the tube length is about 60 meters, and the material enters from the inlet end; at 1.0 meters from the material inlet end, a plunger metering pump is used to feed the hydroxyacetonitrile aqueous solution at a rate of 400 kg / hour The speed continuous feeding is mixed and reacted with the preheated carbon dioxide and ammonia water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com