Patents

Literature

37results about How to "Eliminate the refining process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for abstracting tea seed oil from camellia oleifera seed

InactiveCN101096612AReduce the number of operationsQuality controllableEnzymesFatty-oils/fats productionCamellia oleiferaSlurry

The invention discloses an extracting method of tea seed oil from tea seed, which comprises the following steps: adopting tea seed core as raw material; grinding to add water to stir into slurry; adding amylase or / and cellulose enzyme to enzymolyze; separating to obtain the product. The invention improves the oil-out rate more than traditional extracting method, which remains more non-oil nourishing element.

Owner:HUNAN AGRICULTURAL UNIV

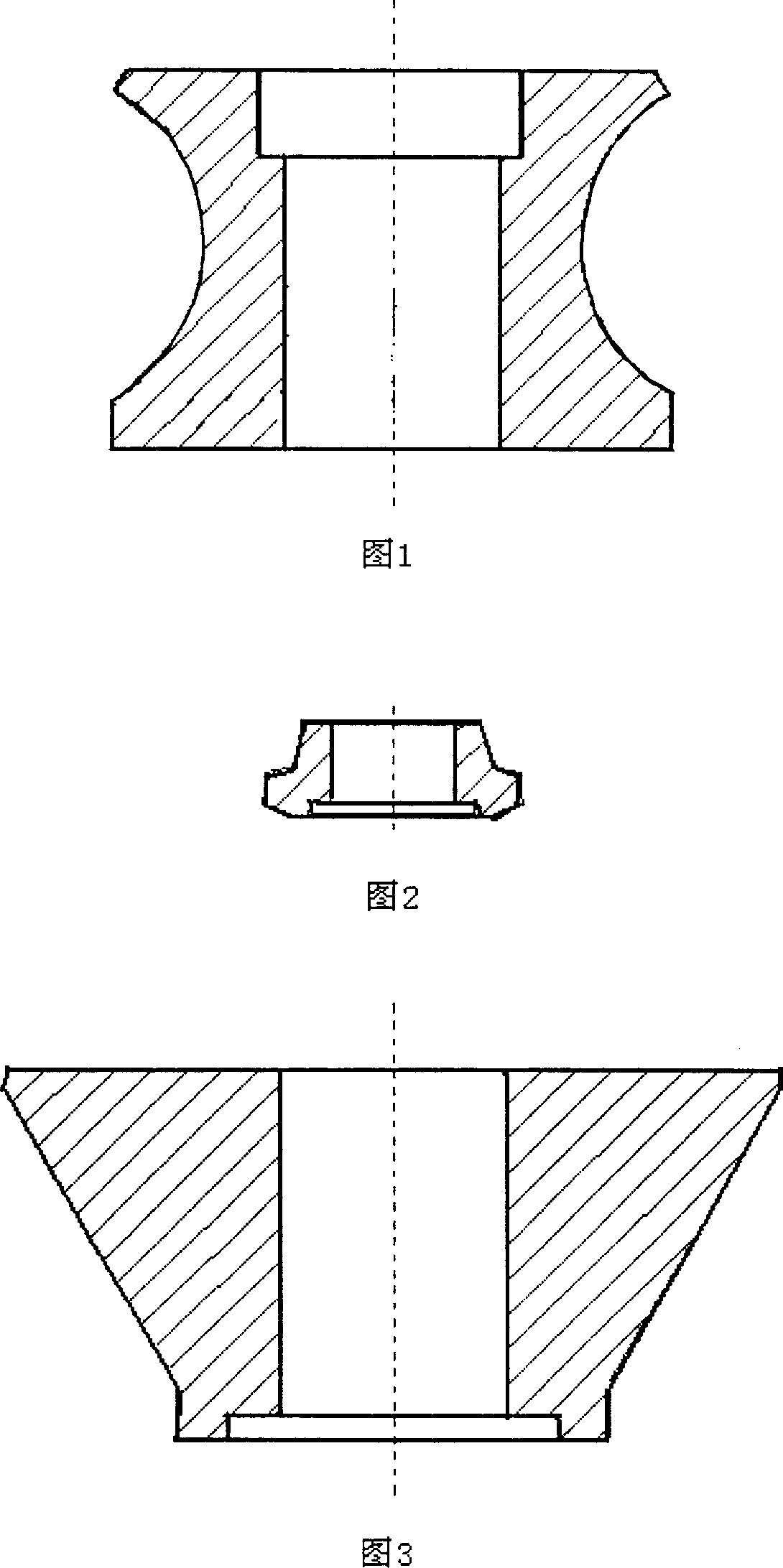

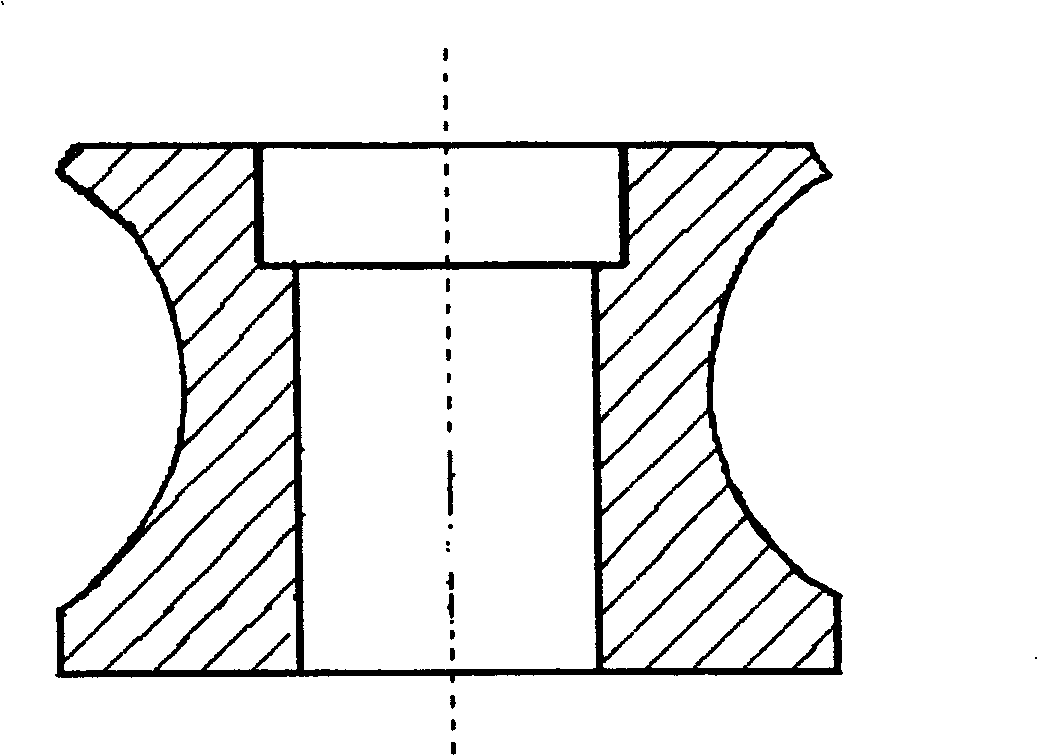

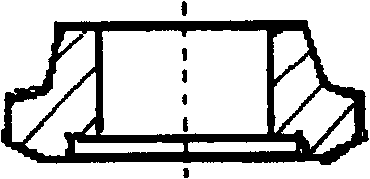

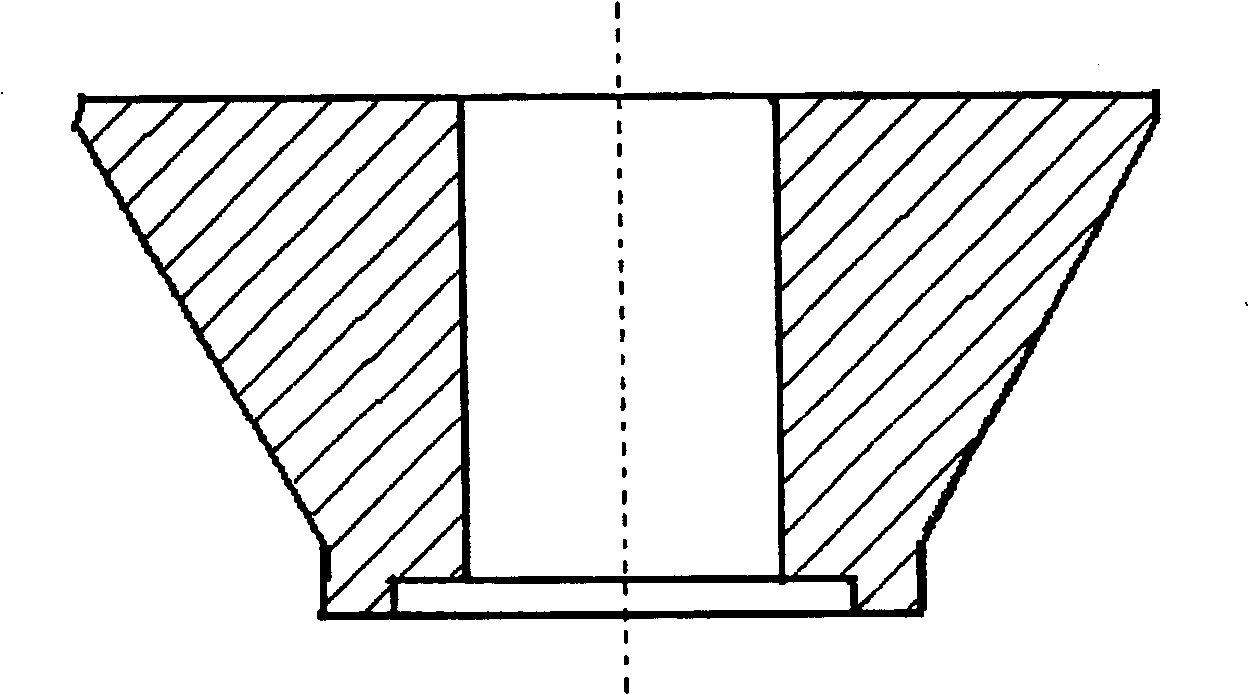

Casting high ferrochrome or casting high chromium steel roll for welding steel pipe

ActiveCN101015836AReduce the amount of processingHigh material utilizationRollsMetal rolling arrangementsSteel tubeFerrochrome

The invention provides a cast high chrome iron or cast high chrome steel roller used to roll weld steel tube and on straight-slim welding steel tube roller, or the like, wherein the cast high chrome iron roller comprises C in 1.8-2.8%, Si <=1.0%, Mn <=1.0%, P<=0.05%, S<=0.05%, Cr in 12-22%, Ni in 0.5-3.0%, Mo in 0. 0%, Ti in 0-0.3%, V in 0-1.0%, Cu in 0-1.0%, RE in 0.01-0.5%, and the left is Fe. The inventive roller has uniform organism, high abrasion resistance and flexibility, while its service life is 2-5 times of general product and material utilization can reach 70% or 80%, with low cost.

Owner:SHANDONG PROVINCE SIFANG TECHN DEV

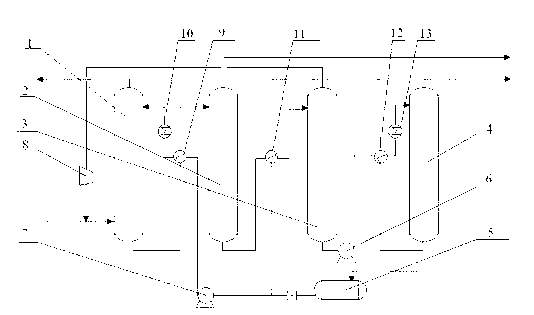

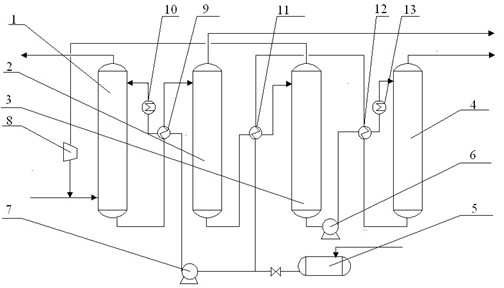

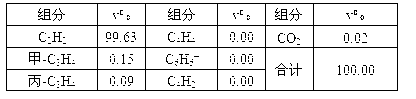

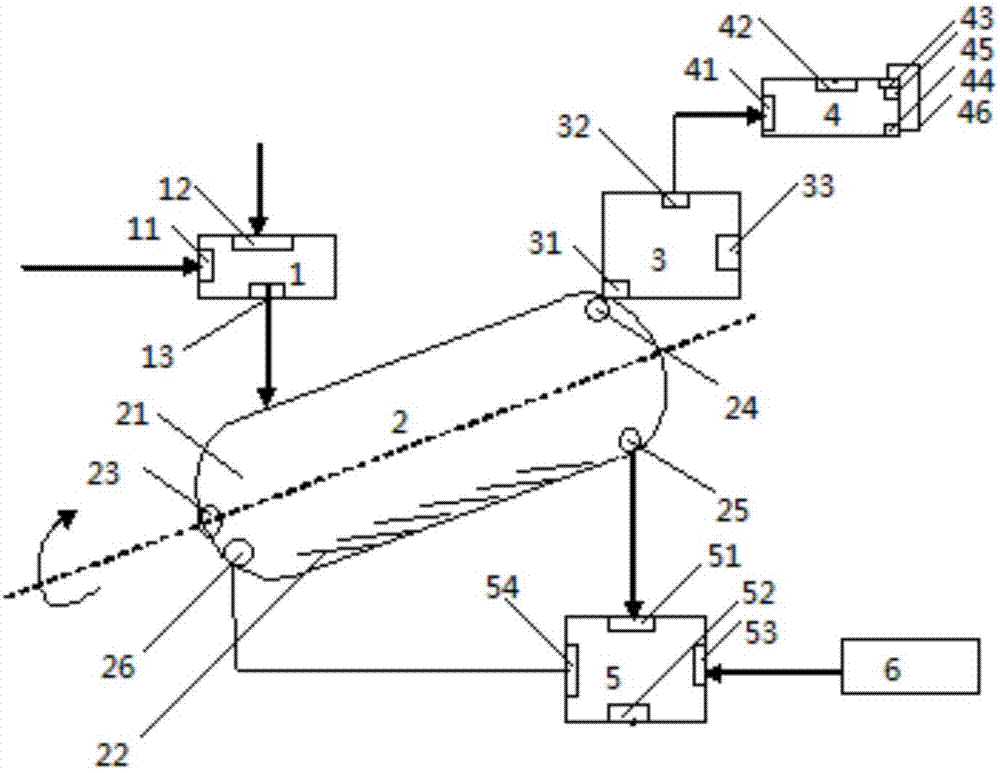

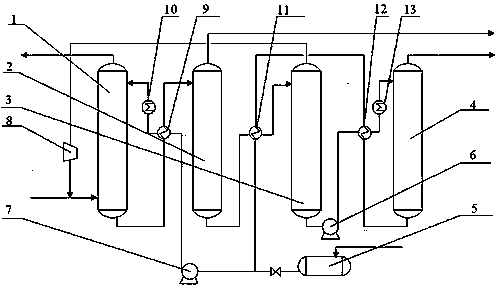

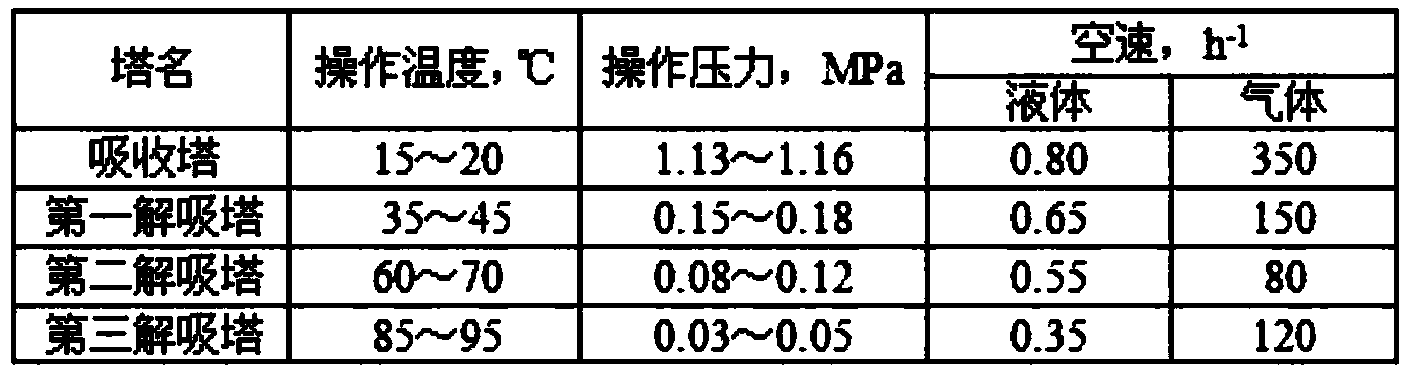

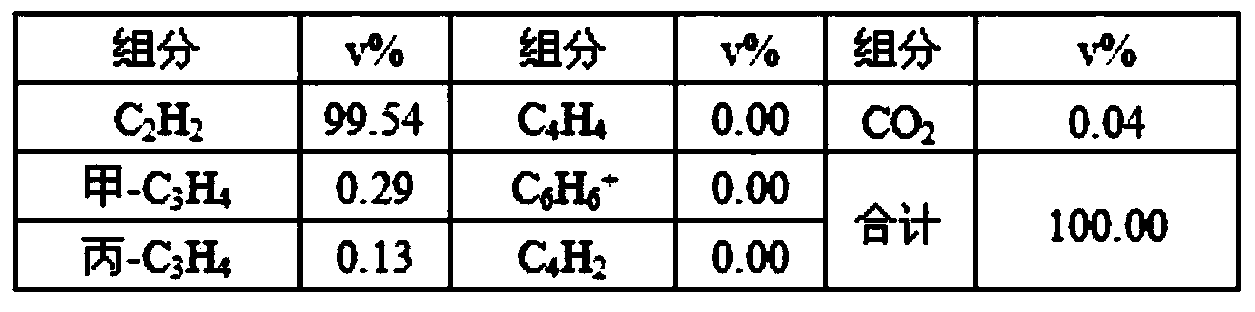

Composite solvent for purifying acetylene and purification method thereof

InactiveCN102701896AHigh selectivityImprove stabilityHydrocarbonsAbsorption purification/separationHigh concentrationAlkyne

The invention relates to a composite solvent used for purifying acetylene in acetylene mixed gas prepared from hydrocarbon and a purification method of the composite solvent. High-purity acetylene and higher alkyne, which are obtained from the acetylene feed gas, can be used as chemical materials. The invention adopts the technical scheme that the components of the composite solvent are as follows in mass percentage: 70-85 percent of physical solvent, 10-20 percent of CO2-removing chemical assistant, 1-5 percent of polymerization inhibitor in an addictive, and 0.5-5 percent of corrosion inhibitor. A device used in the purification method consists of an absorption tower, three desorbers and accessory equipment; the feed gas is firstly in countercurrent contact with the composite solvent in the absorption tower, wherein the acetylene, the higher alkyne and CO2 are absorbed by the composite solvent, then the high-concentration acetylene is absorbed out in the first desorber, the residual acetylene is absorbed out in the second desorber, and the higher alkyne and the CO2 are absorbed out in the third desorber. The composite solvent is high in selectivity, excellent in stability and easy to regenerate; and the purification method is simple in flow and mild in operation conditions, and the acetylene product whose purity is higher than 99.5 percent can be obtained.

Owner:SOUTHWEST PETROLEUM UNIV

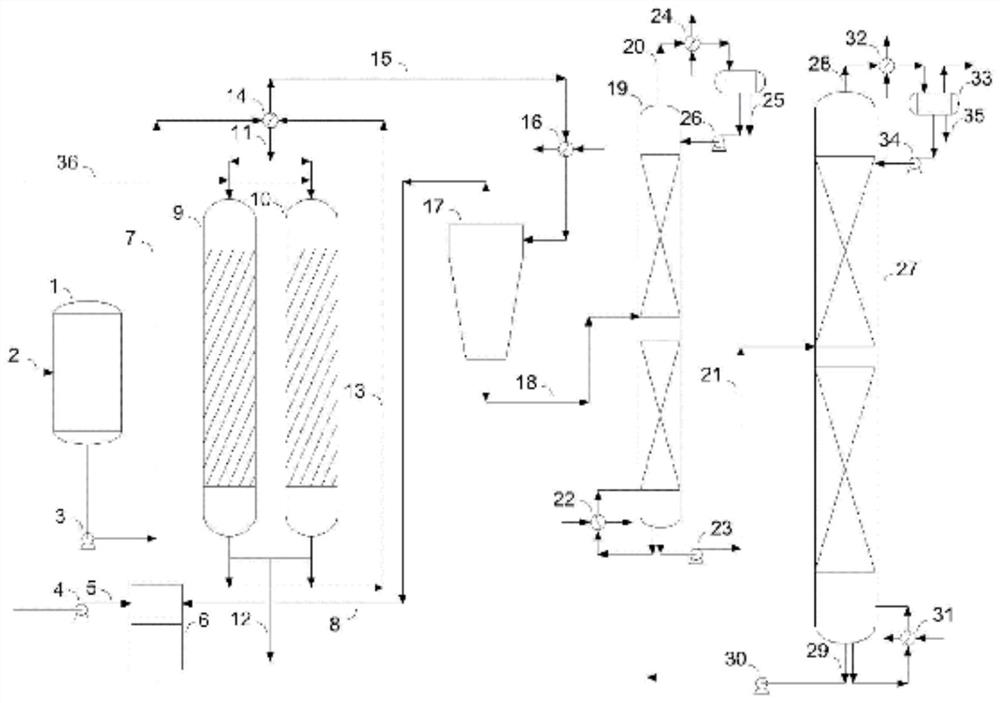

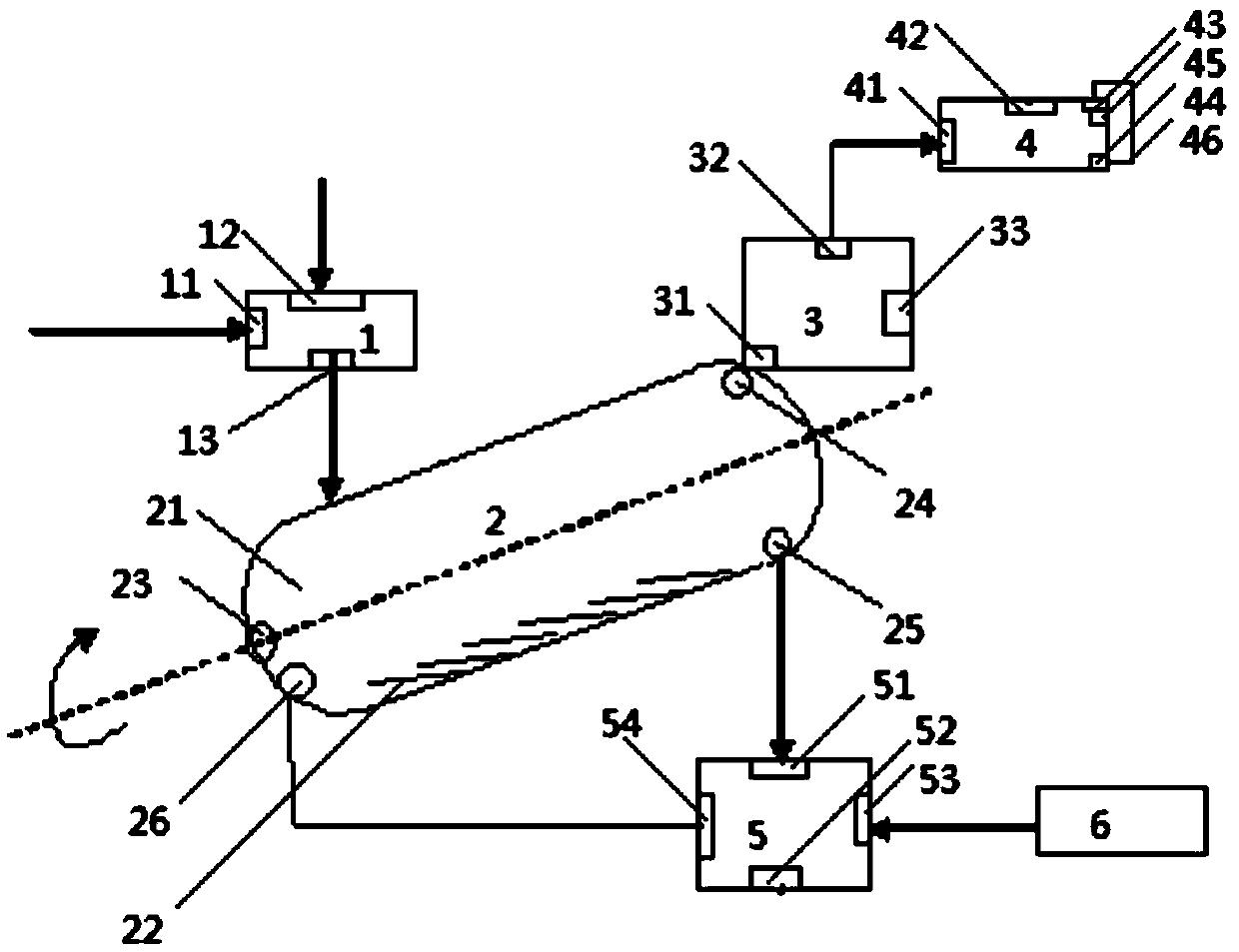

Static mixed rotational flow separation and extraction process of regenerative base oil N-methyl pyrrolidone

The invention relates to a static mixed rotational flow separation and extraction process of regenerative base oil N-methyl pyrrolidone, comprising the following steps in sequence: (a) carrying out sedimentation of used oil and removing moisture and solid impurities; (b) filtering by a filter, and removing tiny solid particles and colloids; (c) adding sodium hydroxide solution and flocculating; (d) removing floccules and residual sodium hydroxide solution; (e) carrying out reduced pressure distillation by a distiller, and collecting distillate oil; (f) mixing the distillate oil with organic solvent by a static mixer on line; (g) separating out raffinate oil and raffinate oil containing organic solvent from mixed liquor by a swirler; (h) carrying out the reduced pressure distillation on the raffinate oil by a climbing film evaporator, and removing the organic solvent in the raffinate oil; and (i) carrying out the reduced pressure distillation by a molecule (short range) distiller, removing residual organic solvent and peculiar smell gas, and obtaining the regenerative base oil. The separation and extraction process provided by the invention has the advantages of conciseness in procedure, safety in operation, less equipment investment, high product yield, energy conservation, environmental friendliness and the like.

Owner:ANHUI GUOFU LUBRICANT IND

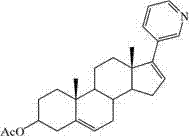

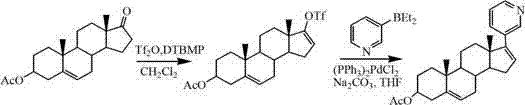

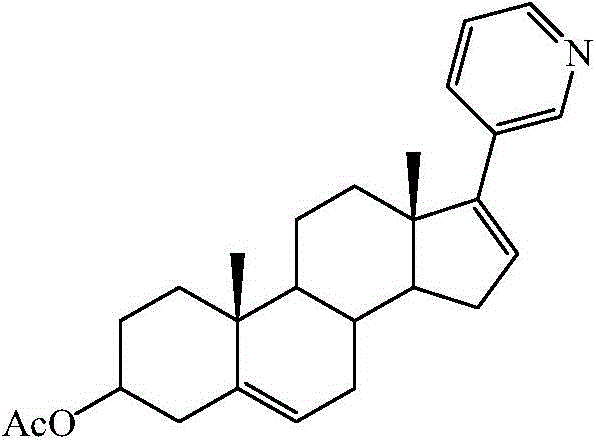

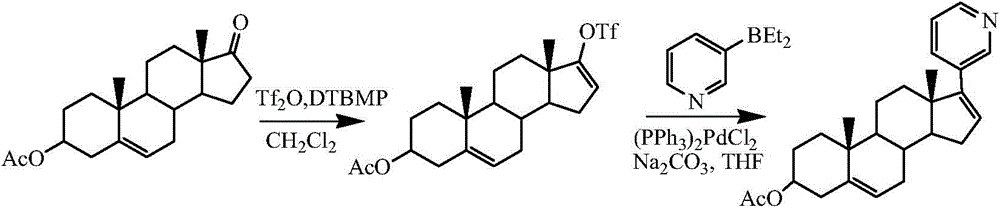

Purifying method for abiraterone acetate

Owner:LUNAN PHARMA GROUP CORPORATION

Preparation method of methyl-glycine diacetate tri-sodium

ActiveCN102993034AEliminate the refining processAchieve preparationOrganic compound preparationAmino-carboxyl compound preparationAcetic acidGlycinonitrile

The invention relates to a preparation method of methyl-glycine diacetate tri-sodium, successively comprising the following steps of: preparation of hydroxy acetonitrile solution, preparation of iminodiacetonitrile solution, preparation of methyl-flycine nitrile diacetonitrile crystal, preparation of methyl-glycine diacetate tri-sodium (MGDA-3Na) and preparation of solid product MGDA-3Na. In the method, the yield of methyl-flycine nitrile diacetonitrile crystal is higher than 92%, the total yield of MGDA-3Na can reach more than 86%, the content of NTA (nitrilotriacetic acid) is less than 0.08%; and the equipment investment and energy consumption in the hydrocyanic acid refining process are saved on the premise that high yield and low toxic side product content are met, and the hydrocyanic acid refining process is not required, so that the production cost is reduced and the environment pollution is reduced.

Owner:CHONGQING UNISPLENDOUR CHEM

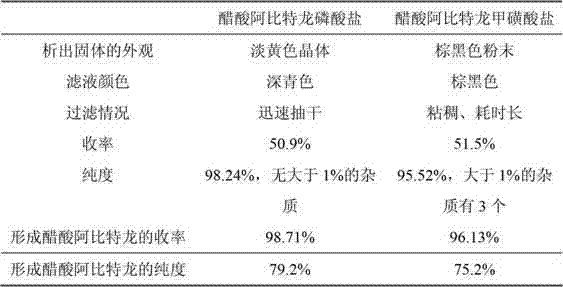

Method for preparing rubber accelerator DM (2,2'-dithiobis(benzothiazole)) from 2-mercaptobenzothiazole coarse product as raw material

A method for preparing a rubber accelerator DM (2,2'-dithiobis(benzothiazole)) from 2-mercaptobenzothiazole coarse product as a raw material is provided and is characterized by comprising the steps of adding water and rubber accelerator coarse product M (2-mercaptobenzothiazole) into a reaction kettle with weight ratio of (1-20) to 1, and adding sodium hydroxide with weight ratio of sodium hydroxide to rubber accelerator coarse product M of 100 to (24-60), and reacting to generate M sodium salt liquid; standing solution, collecting supernatant and adding into an oxidation pot, dripping a mixed solution containing hydrogen peroxide with concentration of 1% to 27.5% and dilute sulphuric acid with concentration of 1% to 30% into the oxidation pot with the flow velocity of 1 to 8 m<3> / h under the condition that the temperature is 20 to 60 DEG C and the mixing speed is 50 to 1000rpm, and stopping dripping oxidant solution till the pH value of the solution reaches 4 to 9; and filtrating and washing DM material with the solution, and removing impurities in DM. The process is simple in process, the solvent can be recovered and recycled for use and the loss is small; and the method is nontoxic and harmless to the people, free from the waste gas and high in environmental protection property.

Owner:KEMAI CHEM

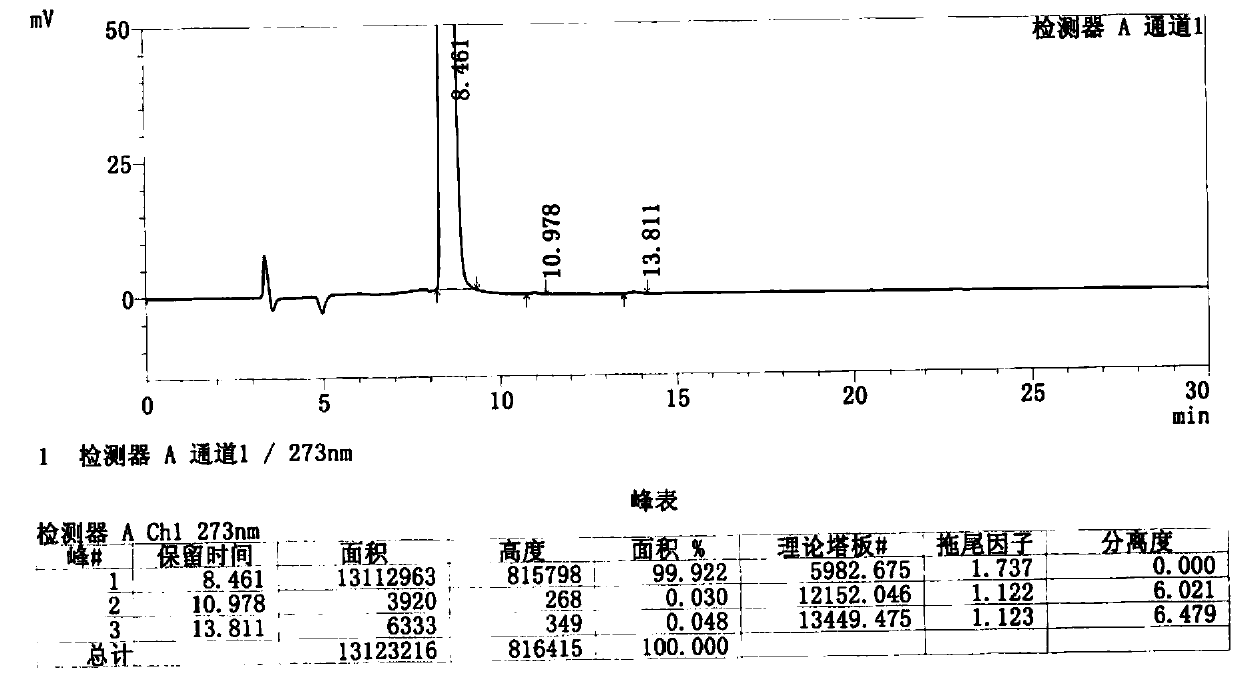

Preparation method of rubber vulcanization accelerator DCBS

InactiveCN102838564AEliminate the refining processReduce the generation of "three wastes"Organic chemistrySaline waterVulcanization

The invention relates to a preparation method of a rubber vulcanization accelerator DCBS. The preparation method comprises the following steps of: directly adding crude MBT obtained in a high-pressure reaction into a container filled with water under violent stirring, dropping a sodium hydroxide aqueous solution into the container to ensure that the MBT is completely dissolved into an M-Na saline solution, standing still, and then transferring supernatant liquor into a measuring tank; simultaneously dropping a sodium hypochlorite solution, the M-Na saline solution and a sulfuric acid solution into a container filled with isopropanol and dicyclohexylamine, and after the M-Na saline solution is finished being dropped, stopping dropping the other two solutions; standing still a reaction mixture obtained at a reaction endpoint, separating out saline water and the isopropanol, wherein the isopropanol is directly recycled; carrying out suction filtration on a material layer, washing a filter cake with water to neutrality, and distilling material washing water to recover the isopropanol; and drying the material to obtain a DCBS finished product. According to the preparation method, because the MBT crude product is used as a raw material to directly synthesize the accelerator, the preparation method has the advantages of simple operation, low cost, small environmental pollution and high yield.

Owner:KEMAI CHEM

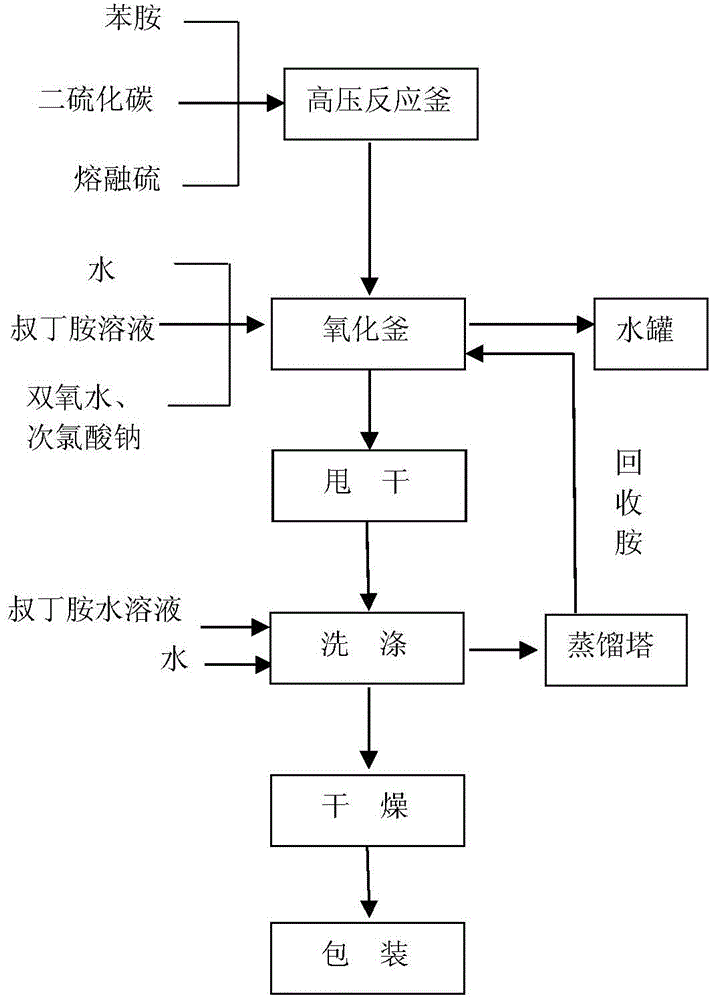

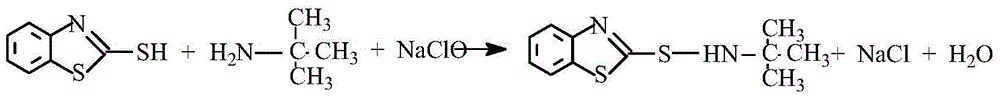

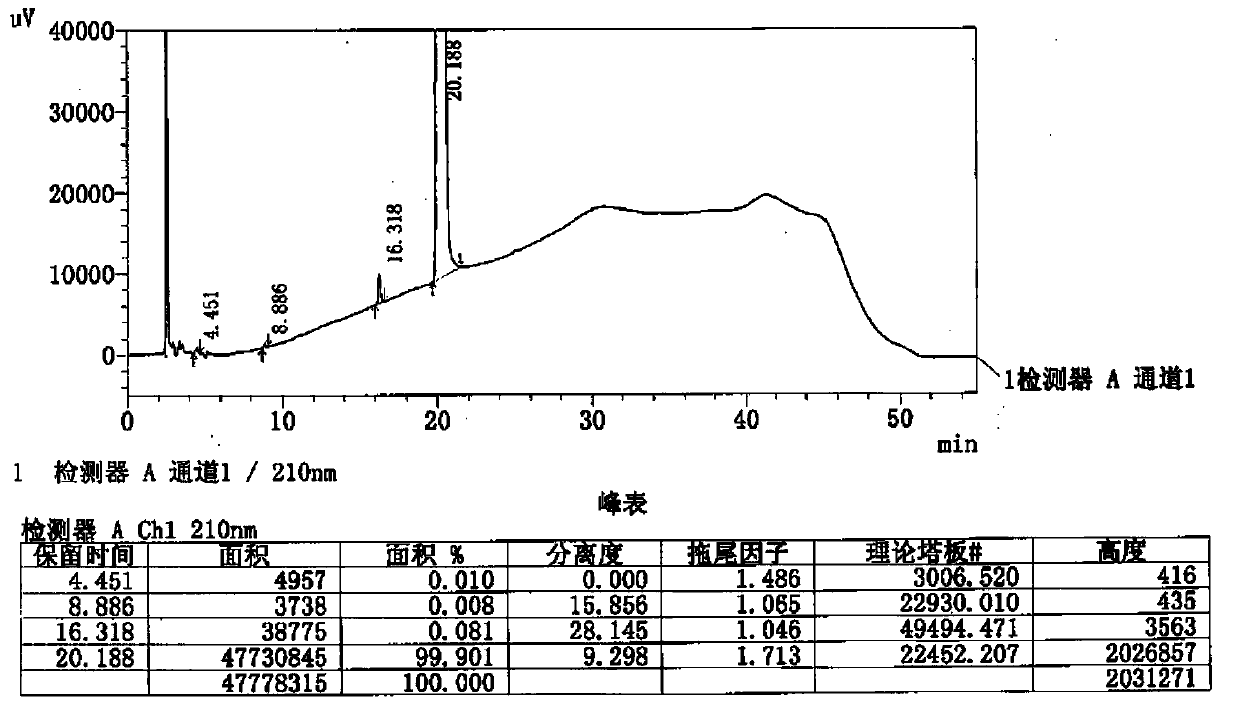

Preparation method of rubber vulcanizing accelerator TBBS

InactiveCN104610193AReduce pollutionReduce Process Safety RisksOrganic chemistryPotassium iodineAccelerant

The invention relates to a preparation method of a rubber vulcanizing accelerator TBBS. The preparation method comprises the following steps: (1), synthesizing a crude product MBT, to be specific, directly adding molten sulfur as raw material sulfur, and eliminating the procedure of dissolving sulfur by carbon disulfide so as to reduce the potential risks of production; (2), synthesizing the accelerant TBBS by the crude product MBT, to be specific, adding the molten crude MBT in an oxidization kettle which contains water and starts stirring, after stirring the molten crude MBT and the water, cooling, and draining; adding a tert-butylamine water solution into the oxidization kettle, after uniformly stirring, adding hydrogen peroxide so as to perform oxidation synthesis, dripping sodium hypochlorite in the later period, and determining the end by using ammonium sulfate and a potassium iodide solution; performing suction filtration after reaction, washing filter cakes by the tert-butylamine water solution, washing the washed filter cakes with water till being neutral, and drying the filter cakes so as to obtain the qualified vulcanizing accelerator TBBS. According to the preparation method disclosed by the invention, the crude MBT is used as raw materials to directly synthesize the accelerant TBBS, the environment-friendly hydrogen peroxide is used as an oxidizing agent, the refining process of MBT is eliminated, waste water containing salt is generated, and little pollution to the environment is caused.

Owner:内蒙古科迈化工有限公司

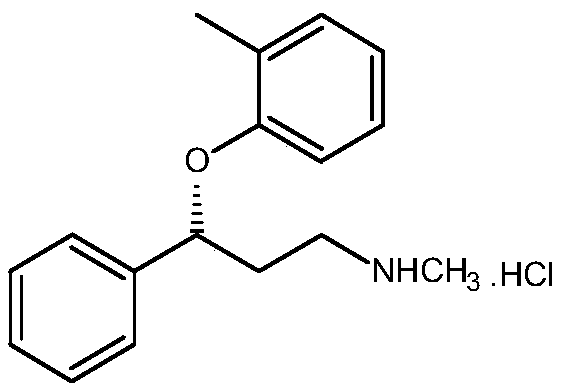

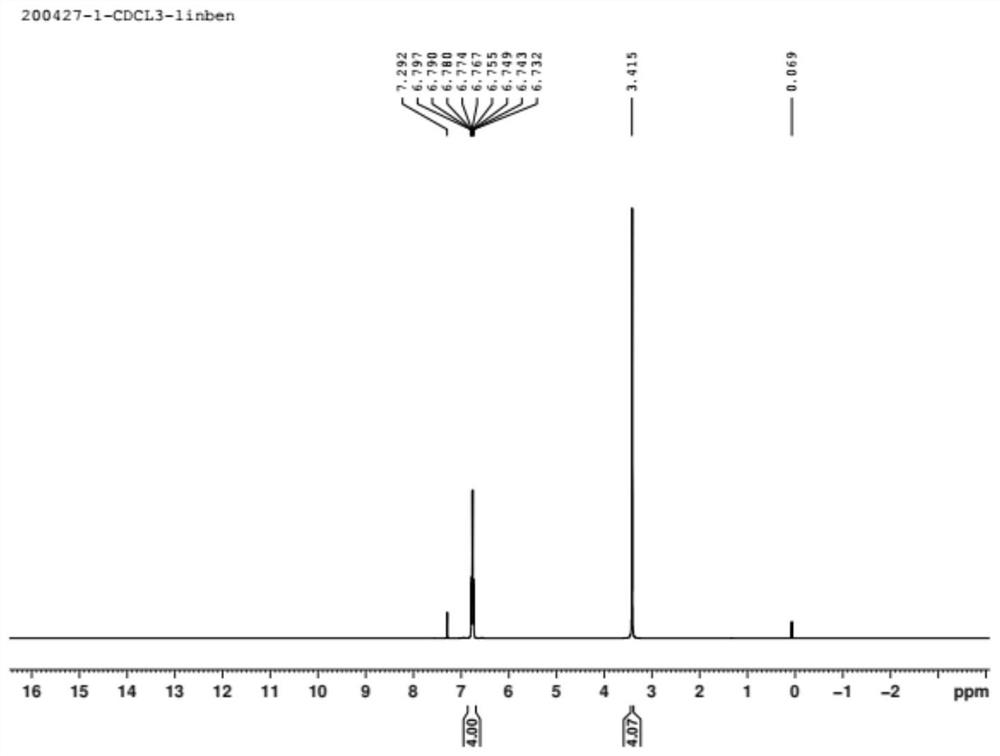

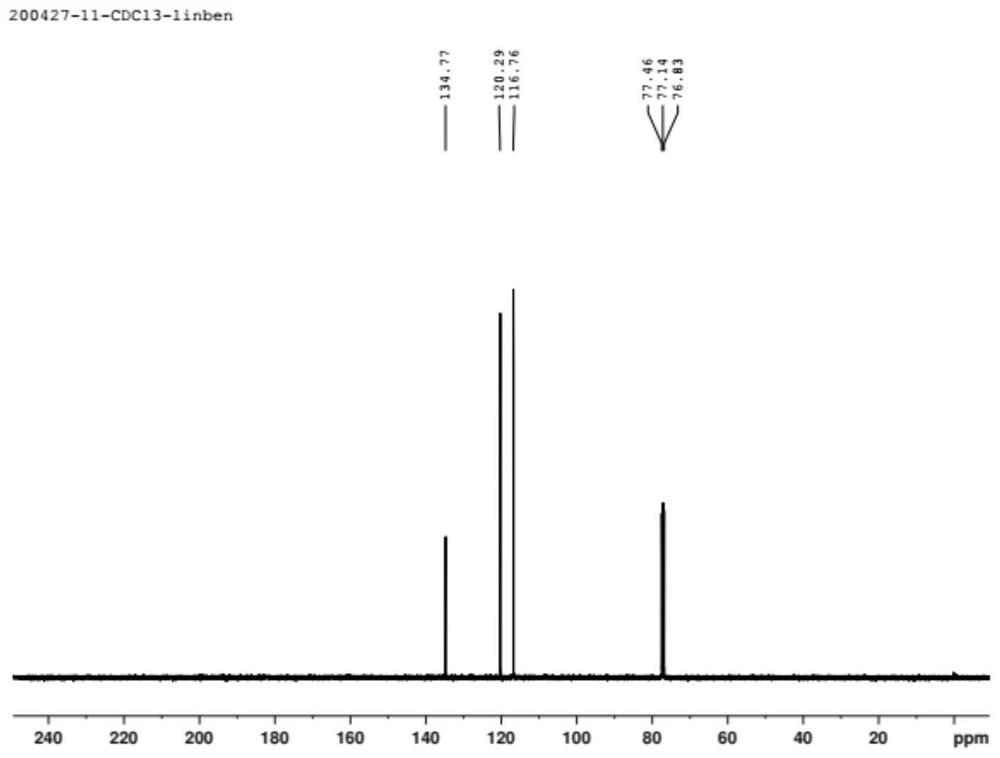

R-(-)-atomoxetine hydrochloride preparation method

ActiveCN110194719AEliminate the refining processFew reaction stepsOrganic compound preparationOrganic chemistry methods1-PropanolSolvent

The invention provides an R-(-)-atomoxetine hydrochloride preparation method, which comprises: preparing 3-methylamino-1-phenyl-1-propanol by using 1-phenyl-2-propenyl-1-one as a starting raw material, carrying out etherification on the 3-methylamino-1-phenyl-1-propanol and o-halo toluene in an inorganic alkali environment, splitting with L-(+)-mandelic acid to obtain R-(-)-tomoxetine-S-(+)-mandelate, refining the R-(-)-tomoxetine-S-(+)-mandelate, and carrying out hydrochloride forming to obtain the R-(-)-atomoxetine hydrochloride. According to the present invention, the method eliminates theoxalate refining step so as to reduce the reaction step, has advantages of cheap and easily available raw materials, less side reactions, low toxicity of the reaction solvent, high yield, high purity,low cost and the like, and is suitable for industrial production.

Owner:SHANDONG UNIV

Preparation method of methyl-glycine diacetate tri-sodium

ActiveCN102993034BEliminate the refining processAchieve preparationOrganic compound preparationAmino-carboxyl compound preparationAcetic acidGlycinonitrile

The invention relates to a preparation method of methyl-glycine diacetate tri-sodium, successively comprising the following steps of: preparation of hydroxy acetonitrile solution, preparation of iminodiacetonitrile solution, preparation of methyl-flycine nitrile diacetonitrile crystal, preparation of methyl-glycine diacetate tri-sodium (MGDA-3Na) and preparation of solid product MGDA-3Na. In the method, the yield of methyl-flycine nitrile diacetonitrile crystal is higher than 92%, the total yield of MGDA-3Na can reach more than 86%, the content of NTA (nitrilotriacetic acid) is less than 0.08%; and the equipment investment and energy consumption in the hydrocyanic acid refining process are saved on the premise that high yield and low toxic side product content are met, and the hydrocyanic acid refining process is not required, so that the production cost is reduced and the environment pollution is reduced.

Owner:CHONGQING UNISPLENDOUR CHEM

Method for production of potassium sulfate from industrial by-product ammonium sulfate

InactiveCN106927487AReduce crystallizationOmit centrifugationSulfate/bisulfate preparationOrganic acidDecomposition

The invention discloses a method for production of potassium sulfate from industrial by-product ammonium sulfate. The method directly uses the industrial by-product ammonium sulfate as the raw material to prepare potassium sulfate with potassium chloride by means of thermal double decomposition, wherein the industrial by-product ammonium sulfate contains a small amount of organic impurities and is obtained as a by-product generated in preparation of organic acid or ester compound by employing an organic nitrile compound or amide compound as the raw material and using sulfuric acid as the catalyst. According to the method provided by the invention, in a heating process of the raw materials, organic impurities in ammonium sulfate can burn and be removed. At the same time, the reaction system utilizes the heat released by organic impurities during burning to promote the thermal double decomposition reaction of ammonium sulfate and potassium chloride, thus reducing energy consumption of the preparation process. At the same time, the problems that ammonium sulfate containing organic impurities cannot be utilized and is difficultly discharged can be solved.

Owner:CHONGQING UNISPLENDOUR CHEM

Acetic ether hydrogenation catalyst and technological method

ActiveCN106622254AReduce energy consumptionEliminate the refining processOrganic compound preparationHydroxy compound preparationEthyl esterEther

The invention relates to acetic ether hydrogenation catalyst and a technological method. The acetic ether hydrogenation catalyst is used to mainly solve the problem that an acetic ether conversion rate and ethyl alcohol selectivity are lower in the prior art. The acetic ether hydrogenation catalyst is prepared from copper of copper oxide, a second component, a third component and a fourth component, wherein the mass content of the copper or the copper oxide is 20 to 70%, the mass content of the second component is 15 to 60%, the mass content of the third component is 1 to 40%, and the mass content of the fourth component is 1 to 20%; the second component is zinc oxide; the third component includes at least one of La2O3, CeO2, ZrO2, Fe2O3, MgO, MnO, B2O3 and K2O; the fourth component is CaO. The technical scheme of the technological method better solves the problem, and the acetic ether hydrogenation catalyst can be applied to acetic ether hydrogenation.

Owner:SHANGHAI HUAYI GRP CO

Novel continuous production method of phenylenediamine

ActiveCN111848408AEliminate the refining processFew reaction stepsAmino compound purification/separationOrganic compound preparationProcess engineeringReaction step

The invention relates to a novel continuous production method of phenylenediamine. The method comprises the steps of nitrification, ammonolysis, reduction, rectification and the like. According to themethod, the reaction steps are reduced, and the intermediate refining process is omitted, so that the production procedure is simplified, the production cost is reduced, the working efficiency is greatly improved, the loss is reduced, the rectification requirement is reduced, the product is easier to separate, the energy consumption is reduced, and finally, the high-purity phenylenediamine product is obtained at high yield.

Owner:杨美玲

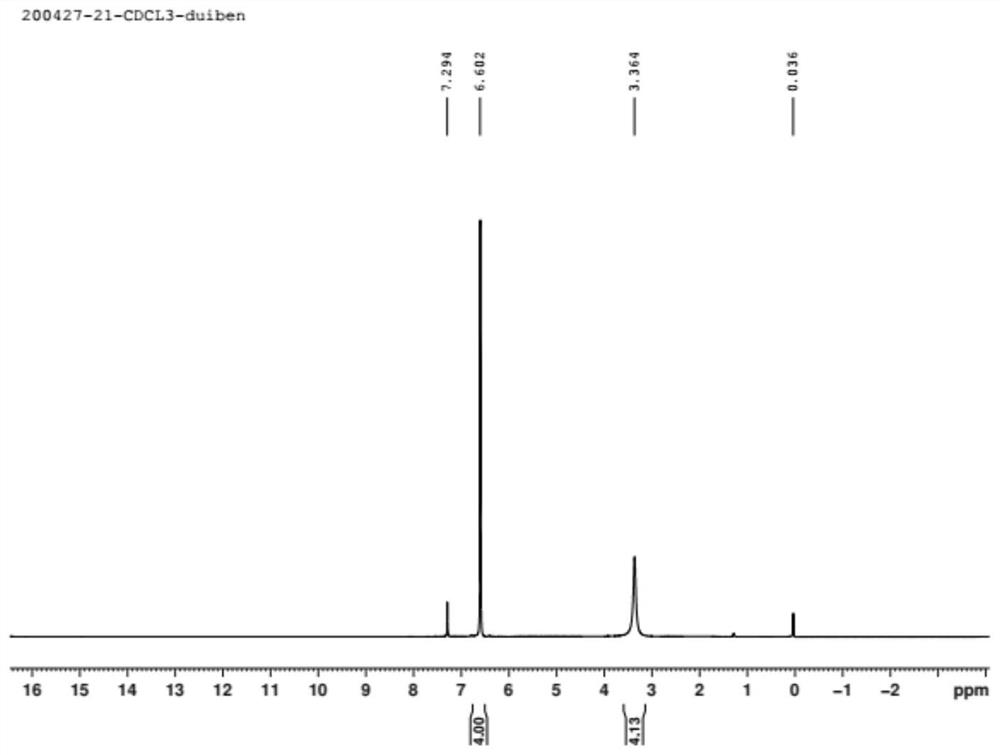

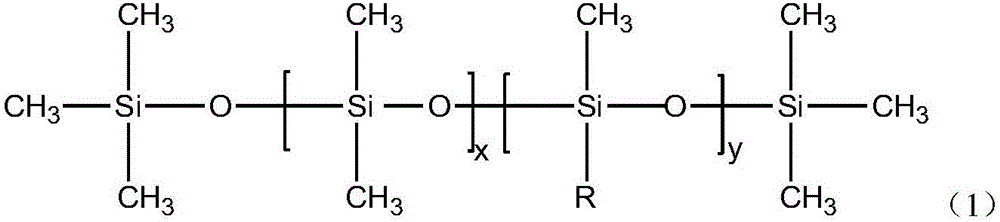

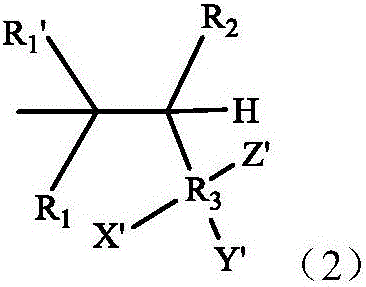

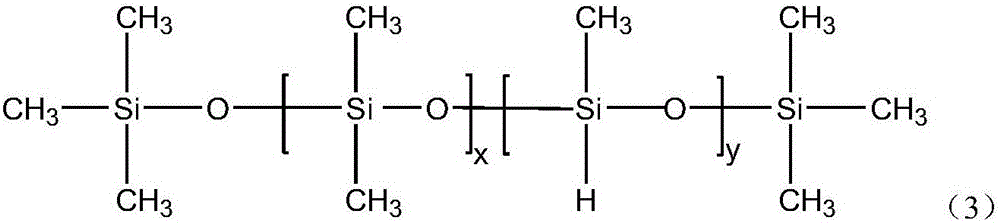

Polyurethane foam stabilizer and preparation method

The invention provides a polyurethane foam stabilizer and a preparation method. The preparation method comprises the following steps of synthesizing of silicone oil with low hydrogen content, synthesizing of unsaturated polyether, synthesizing of isocyanate-terminated unsaturated polyether, and reacting of the silicone oil with low hydrogen content and the isocyanate-terminated unsaturated polyether, so as to obtain the polyurethane foam stabilizer. The preparation method has the advantages that the unsaturated polyether-terminated polyester uses isocyanate as a end-capping reagent, the usage amount is less, the reaction time is short, the waste salt is not produced, the product quality is stable, and the cost is low; the reaction activity is strong, the property is excellent, the problem of existence of terminating in the existing alkyl terminating and unsaturated polyether is solved, and the variety of the existing polyurethane foam stabilizer is enriched by adjusting the type of the isocyanate end-capping reagent.

Owner:联泓(江苏)新材料研究院有限公司

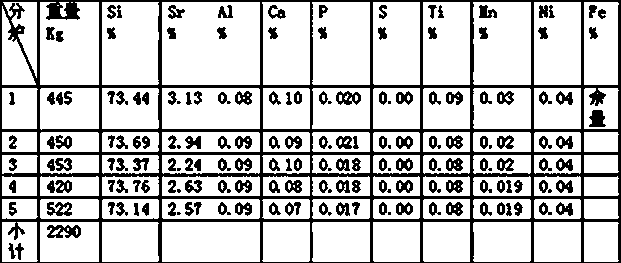

Method for producing strontium-silicon alloy by utilizing high-purity ferrosilicon powder

The invention relates to the field of smelting and in particular relates to a method for producing a strontium-silicon alloy by utilizing high-purity ferrosilicon powder. The method comprises the following steps: preparing raw materials comprising high-purity silicon powder with the purity of 73-75% and metal strontium having the purity of more than 99%, wherein the total content of aluminum and calcium in the silicon powder is less than 0.05% of the total weight of the silicon powder; smelting the high-purity silicon powder, namely performing random layered feeding in an induction furnace crucible until the raw material is totally molten; adding a dreg remover, stirring, polymerizing to remove the surface residues; adding the metal strontium in blocks, and uniformly stirring; enabling thesolution to flow out of an ingot mold after mixing, clipping out when the surface is dark red, transporting to a processing workshop for crushing, screening, and packaging the finished product. Sincesmelting electricity for high-purity ferrosilicon is saved, the cost is greatly reduced. Finally, the obtained material has the components that the content of Si is equal to 72-75%, the content of Sris equal to 0.6-2.2%, the content of Al is equal to 0.1%, and the content of Ca is equal to 0.1%.

Owner:商洛德新诚机械铸件有限公司

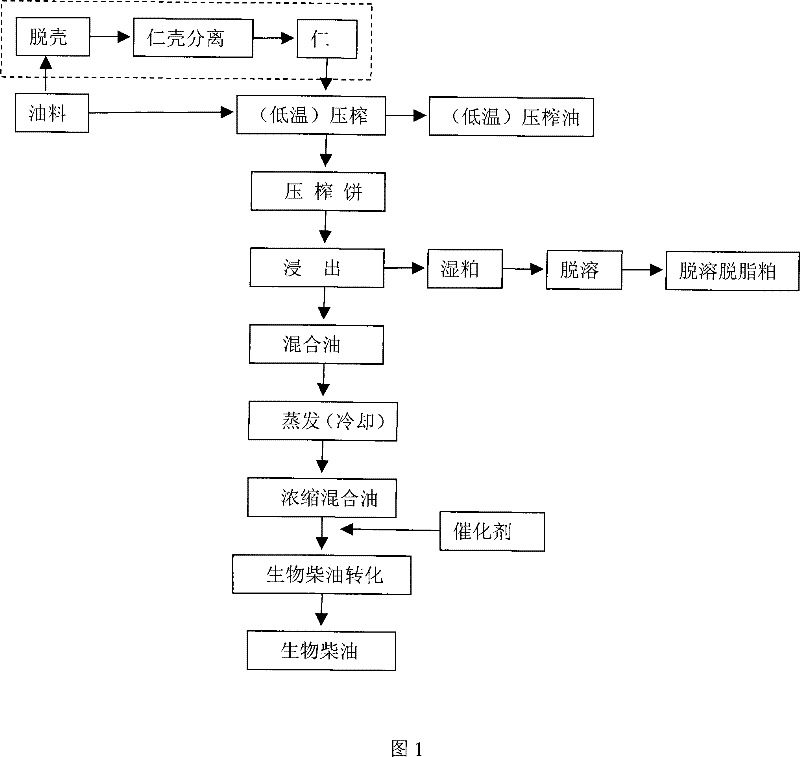

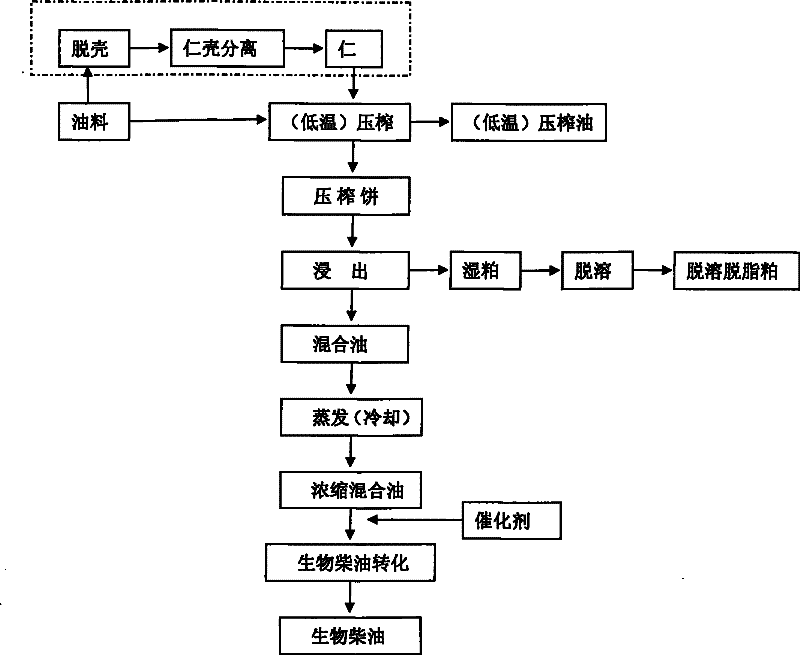

Method for extracting conversion biodiesel from oil pressing cake

InactiveCN101161784BQuality improvementHigh priceFatty oils/acids recovery from wasteBiofuelsOil and greaseBiodiesel

The invention relates to a method for extracting transformation biodiesel from oil-bearing press cake and solves the problems of complex pretreatment and high energy consumption, etc. of the prior art which mainly adopts animal and vegetable oil as raw materials. The invention realizes direct pressing of shelled oilseeds or unshelled oilseeds through a low-temperature screw oil press or a common oil press to obtain press cake and expressed oil; the press cake is leached out through adopting organic solvent with the leaching out solvent ratio ranging between 0.8:1 and 2.0:1 and the leaching out time ranging from 60 min to 200 min; the leached out oil mixtures is converted into 60 percent to 90 percent concentrated oil mixtures after evaporation or cooling and separation, while the leached out wet meal containing solvent is converted into degreased meal with the residual oil rate being less than or equal to 1 percent after exsolution; catalyst which accounts 1 percent to 10 percent of the weight of the concentrated oil mixtures is added in the concentrated oil mixtures for biodiesel transformation with the products separated to obtain biodiesel crude product and glycerol; finally, the biodiesel crude product is made into biodiesel product after distillation. The invention which omits steps such as steam stripping and refining has the characteristics of simple process and low energy consumption, etc.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

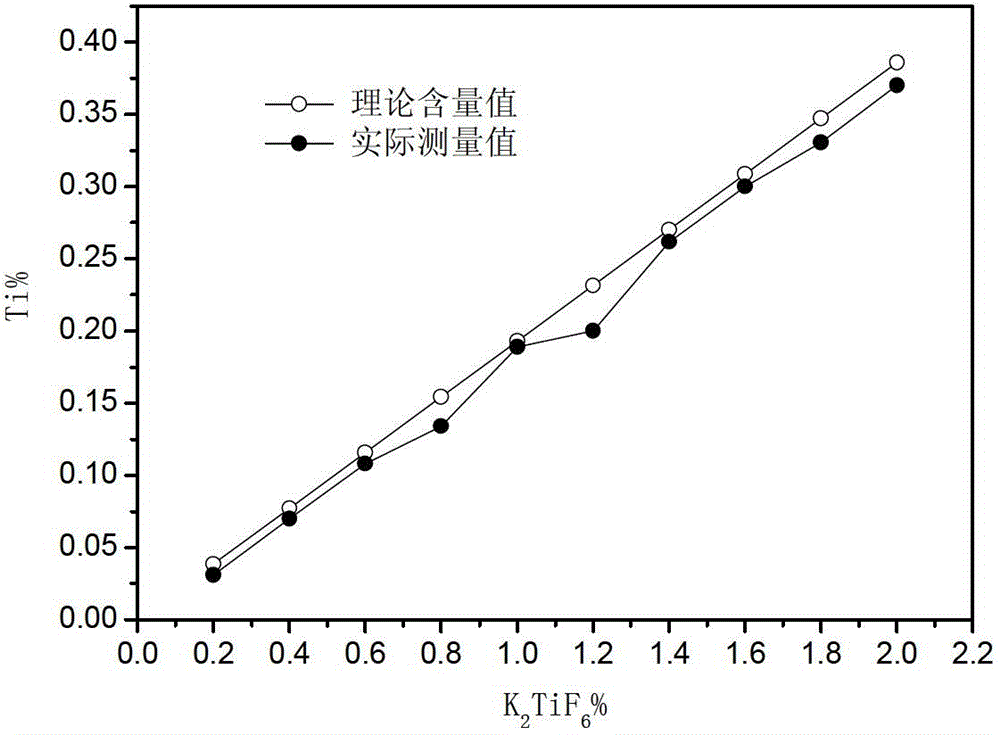

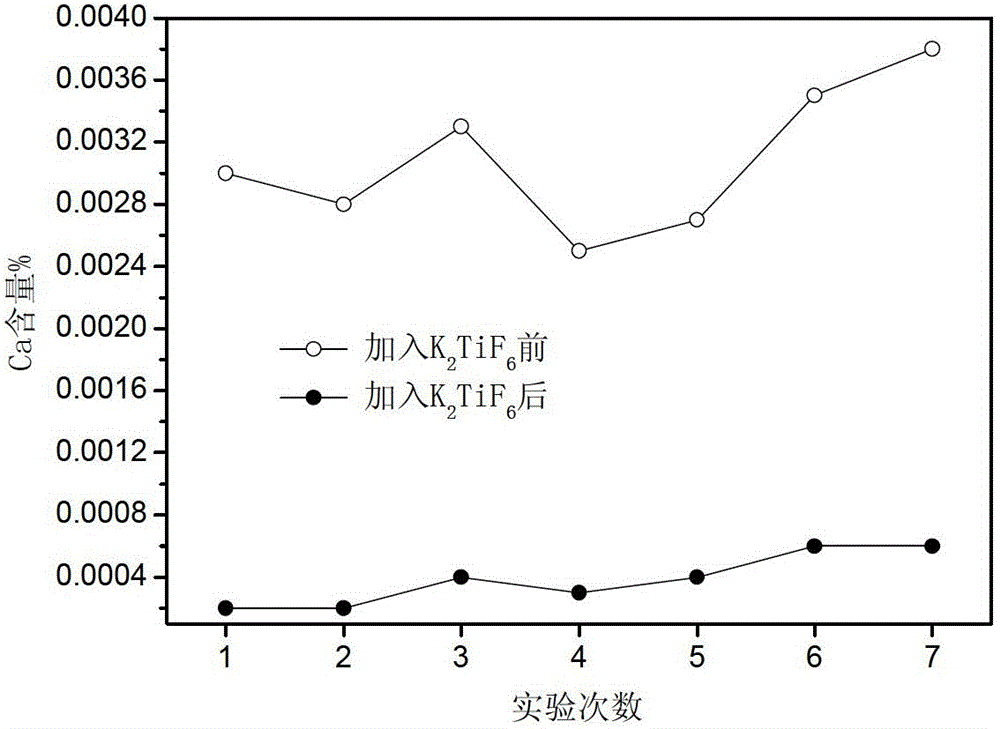

Method for adding grain refinement element Ti into cast aluminum silicon alloy

The invention relates to a method for adding the grain refinement element Ti into cast aluminum silicon alloy. The method comprises the following concrete steps: (1) calculating the usage amount of titanium salt according to the demand of the titanium content in the cast aluminum silicon alloy, weighing and drying for 2-3 h in a constant temperature preheating and drying furnace with a temperature of 200-300 DEG C; (2) when the temperature of a cast aluminum silicon alloy melt reaches 700-760 DEG C, adding the preheated titanium salt into the surface of the aluminum alloy melt in a melting furnace, and stirring for 10-15 min by using a graphite stirring rod under a covering layer; and (3) fully stirring a cast aluminum silicon alloy solution, sampling to measure the components of the cast aluminum silicon alloy solution, and when the Ti content in the cast aluminum silicon alloy is close to the theoretical calculation value, removing dross generated on the surface from the melt, so as to achieve the effects of adding the Ti into the aluminum alloy solution, refining and removing calcium. According to the method, powdery potassium fluotitanate is selected as a refinement element for refinement and calcium removal of the aluminum alloy melt, the steps of preparing intermediate alloy, refining and degassing are removed, and the energy-saving and emission-reduction effects in the production process are achieved.

Owner:天津新立中合金集团有限公司

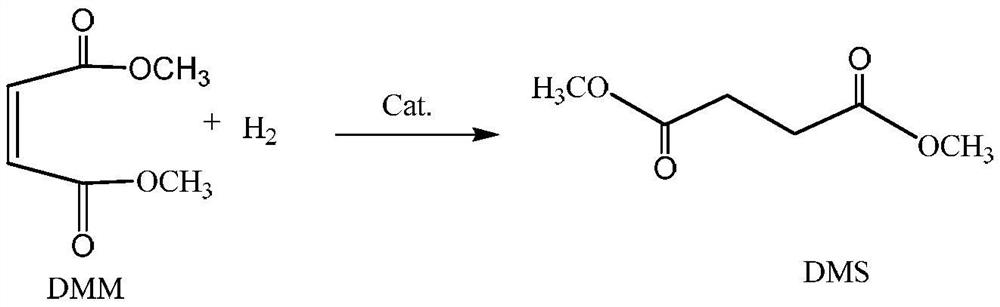

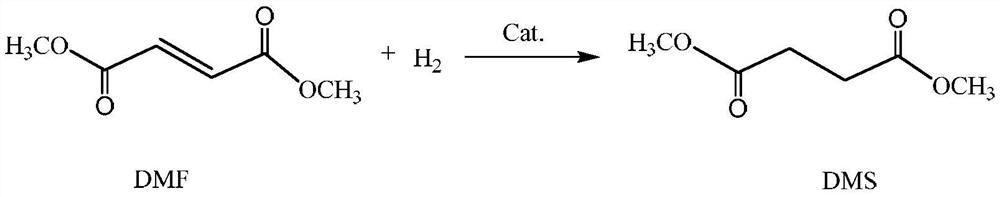

Process method for preparing succinic acid glycol ester

InactiveCN113200853AEliminate the refining processSimple processOrganic compound preparationChemical industryButanedioic acidPtru catalyst

The invention discloses a process method for preparing succinic acid glycol ester, which is characterized by comprising the following steps of: (1) mixing crude maleic acid glycol ester with a proper amount of circulating hydrogen and supplementary new hydrogen, preheating to a certain temperature, feeding the mixture into a fixed bed filled with a catalyst, and carrying out hydrogenation reaction to generate a mixture mainly comprising corresponding succinic acid glycol ester; (2) preheating the raw materials, namely, crude maleic acid glycol ester and hydrogen, by a reaction product and residual hydrogen, generating steam through a steam pocket to realize waste heat utilization, then cooling to below 35 DEG C, feeding the mixture into a gas-liquid separator, and separating out a liquid mixture mainly comprising succinic acid glycol ester and hydrogen; and (3) carrying out double-tower rectification on the liquid mixture mainly comprising succinic acid glycol ester to realize light component removal and heavy component removal to obtain the succinic acid glycol ester with the purity of more than 99.5%. Compared with the prior art, the process method for preparing succinic acid glycol ester is simple in technological process, low in energy consumption and high in product yield.

Owner:宁波窦氏化学科技有限公司

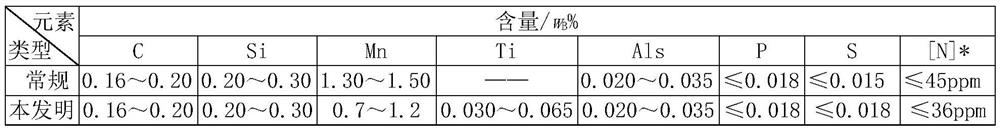

A kind of smelting production method of titanium microalloyed low-cost q355b steel plate

ActiveCN110229992BReduce manganese alloy contentReduce manufacturing costProcess efficiency improvementSmelting processManganese

The invention discloses a smelting production method of a titanium microalloyed low-cost Q355B steel plate. The method comprises the steps of 1, acquiring raw materials, specifically, low-sulfur and low-phosphorus molten iron is slected; 2, smelting through a converter, specifically, deep dephosphorization is carried out by adopting a double slag smelting process; 3, tapping, specifically, any point blowing operations are avoided at the smelting end point, a silicon-manganese alloy is added for deoxidation during the tapping process, and the slag thickness in a molten steel tank is less than or equal to 40 mm after tapping; 4, carrying out argon station treatment, specifically, after molten steel reaches an argon station, argon bottom blowing is kept, an aluminum wire is fed immediately, the Als content in the molten steel is 0.020%-0.040% after the aluminum wire is fed, argon soft blowing is kept for 2-3 minutes, the fine adjustment of the alloy is completed during the period of the argon soft blowing, and then a titanium silicon calcium composite core wire is immediately fed; and 5, continuous casting to carry out protective pouring in the whole process to ensure the Als loss less than or equal to 0.003%. According to the method, titanium microalloying is adopted, and thus, the production cost of Q355B is reduced, and the purity of the molten steel is improved.

Owner:武汉钢铁有限公司

A kind of method utilizing industrial by-product ammonium sulfate to produce potassium sulfate

InactiveCN106927487BReduce crystallizationOmit centrifugationSulfate/bisulfate preparationOrganic acidDecomposition

The invention discloses a method for production of potassium sulfate from industrial by-product ammonium sulfate. The method directly uses the industrial by-product ammonium sulfate as the raw material to prepare potassium sulfate with potassium chloride by means of thermal double decomposition, wherein the industrial by-product ammonium sulfate contains a small amount of organic impurities and is obtained as a by-product generated in preparation of organic acid or ester compound by employing an organic nitrile compound or amide compound as the raw material and using sulfuric acid as the catalyst. According to the method provided by the invention, in a heating process of the raw materials, organic impurities in ammonium sulfate can burn and be removed. At the same time, the reaction system utilizes the heat released by organic impurities during burning to promote the thermal double decomposition reaction of ammonium sulfate and potassium chloride, thus reducing energy consumption of the preparation process. At the same time, the problems that ammonium sulfate containing organic impurities cannot be utilized and is difficultly discharged can be solved.

Owner:CHONGQING UNISPLENDOUR CHEM

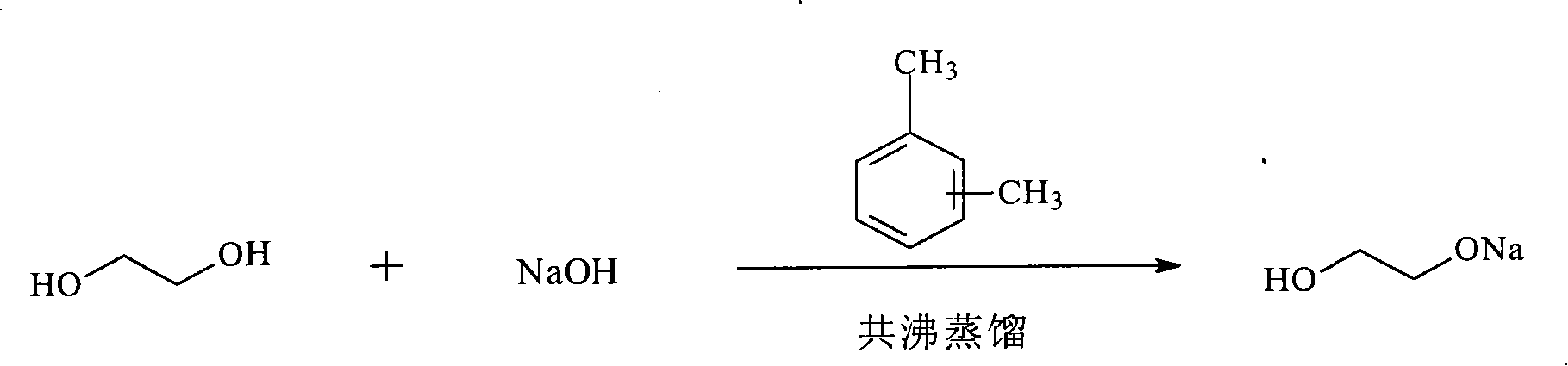

Method for synthesizing 1,4-dioxane-2-ketone by ethylene glycol

Owner:NANTONG FINC PHARMA CHEM +1

A kind of preparation method of r-(-)-atomoxetine hydrochloride

ActiveCN110194719BEliminate the refining processFew reaction stepsOrganic compound preparationOrganic chemistry methodsMandelic acidSide reaction

The invention provides an R-(-)-atomoxetine hydrochloride preparation method, which comprises: preparing 3-methylamino-1-phenyl-1-propanol by using 1-phenyl-2-propenyl-1-one as a starting raw material, carrying out etherification on the 3-methylamino-1-phenyl-1-propanol and o-halo toluene in an inorganic alkali environment, splitting with L-(+)-mandelic acid to obtain R-(-)-tomoxetine-S-(+)-mandelate, refining the R-(-)-tomoxetine-S-(+)-mandelate, and carrying out hydrochloride forming to obtain the R-(-)-atomoxetine hydrochloride. According to the present invention, the method eliminates theoxalate refining step so as to reduce the reaction step, has advantages of cheap and easily available raw materials, less side reactions, low toxicity of the reaction solvent, high yield, high purity,low cost and the like, and is suitable for industrial production.

Owner:SHANDONG UNIV

Casting high ferrochrome or casting high chromium steel roll for welding steel pipe

ActiveCN100423858CEliminate the refining processIncrease profitRollsMetal rolling arrangementsPipeFerrochrome

The invention provides a cast high chrome iron or cast high chrome steel roller used to roll weld steel tube and on straight-slim welding steel tube roller, or the like, wherein the cast high chrome iron roller comprises C in 1.8-2.8%, Si <=1.0%, Mn <=1.0%, P<=0.05%, S<=0.05%, Cr in 12-22%, Ni in 0.5-3.0%, Mo in 0. 0%, Ti in 0-0.3%, V in 0-1.0%, Cu in 0-1.0%, RE in 0.01-0.5%, and the left is Fe. The inventive roller has uniform organism, high abrasion resistance and flexibility, while its service life is 2-5 times of general product and material utilization can reach 70% or 80%, with low cost.

Owner:SHANDONG PROVINCE SIFANG TECHN DEV

Composite solvent for purifying acetylene and purification method thereof

InactiveCN102701896BHigh selectivityImprove stabilityHydrocarbonsAbsorption purification/separationHigh concentrationPurification methods

The invention relates to a composite solvent used for purifying acetylene in acetylene mixed gas prepared from hydrocarbon and a purification method of the composite solvent. High-purity acetylene and higher alkyne, which are obtained from the acetylene feed gas, can be used as chemical materials. The invention adopts the technical scheme that the components of the composite solvent are as follows in mass percentage: 70-85 percent of physical solvent, 10-20 percent of CO2-removing chemical assistant, 1-5 percent of polymerization inhibitor in an addictive, and 0.5-5 percent of corrosion inhibitor. A device used in the purification method consists of an absorption tower, three desorbers and accessory equipment; the feed gas is firstly in countercurrent contact with the composite solvent in the absorption tower, wherein the acetylene, the higher alkyne and CO2 are absorbed by the composite solvent, then the high-concentration acetylene is absorbed out in the first desorber, the residual acetylene is absorbed out in the second desorber, and the higher alkyne and the CO2 are absorbed out in the third desorber. The composite solvent is high in selectivity, excellent in stability and easy to regenerate; and the purification method is simple in flow and mild in operation conditions, and the acetylene product whose purity is higher than 99.5 percent can be obtained.

Owner:SOUTHWEST PETROLEUM UNIV

Converter vacuum steelmaking method

InactiveCN103060507AQuick removalEfficient removalManufacturing convertersProcess efficiency improvementSteelmakingHydrogen

The invention relates to a converter vacuum steelmaking method comprising the steps that: the converter is leaned forward by 15-20 DEG, and iron blending is carried out; the converter is leaned forward by 20-30 DEG, and scrap steel is added; the converter is swung to a blowing position; a vacuuming device is started; the pressure above molten steel in the converter is reduced to 1.33*10<-1> Pa to 133.3Pa; oxygen blowing and smelting are carried out; the vacuuming device is turned off, and sampling and temperature measuring are carried out; and furnace turning and discharging are carried out. With the method, contents of gases such as nitrogen, hydrogen, oxygen, and the like in molten steel can be effectively removed, such that decarbonization and deoxidation reactions can be promoted, metal and non-metal impurities can be reduced, molten steel purity can be improved, and product quality can be improved.

Owner:LAIWU IRON & STEEL GRP

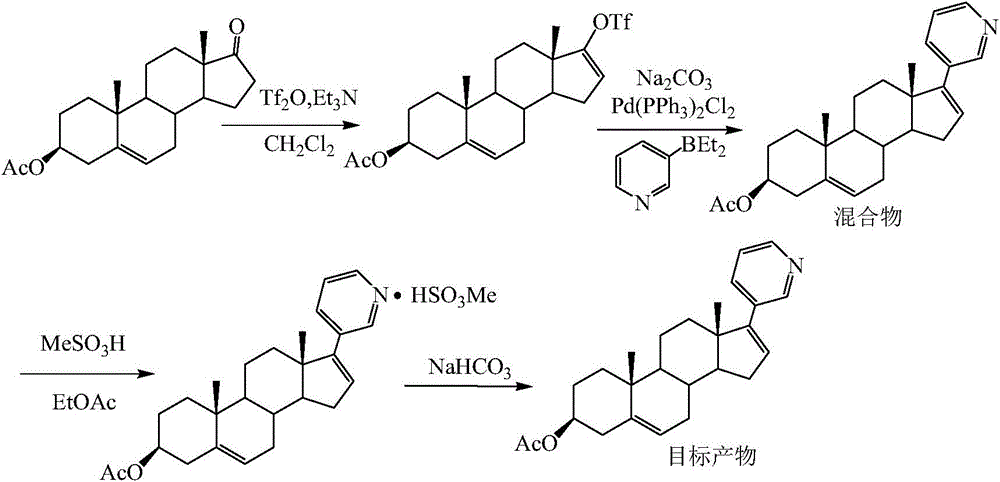

A kind of purification method of abiraterone acetate

The present invention provides a purifying method for abiraterone acetate. According to the method, phosphoric acid is adopted as a salt forming reagent to react with a abiraterone acetate crude product to obtain a light yellow crystal, wherein the light yellow crystal is the abiraterone acetate phosphate, is easily filtered, and has the purity more than 98%, the abiraterone acetate phosphate can be used for the next reaction without further purification to prepare the abiraterone acetate, and the purity of the abiraterone acetate prepared by freeing can be more than 98%; the purification process is simplified, the production cost is reduced, and the method is suitable for industrial production.

Owner:LUNAN PHARMA GROUP CORPORATION

Method for reducing microporosity of casting silicon-aluminum alloy

InactiveCN108315607AImprove liquidityEliminate Casting Performance DropsAcetic anhydrideNitrogen gas

The invention belongs to the technical field of casting silicon-aluminum alloy, and particularly relates to a method for reducing microporosity of casting silicon-aluminum alloy. The method comprisesthe following steps that raw materials are prepared, the raw materials are added into a melting pool at 740 DEG C for melting, after keeping 5-10 minutes, the raw materials are heated up to 800-820 DEG C; when the raw materials are cooled down to 650-670 DEG C, acetic anhydride with the weight counting for 0.8-1.2% of furnace burden is added, slagging-off, discharging from a furnace and casting are carried out after treatment for 6-10 minutes, and heat treatment is carried out after the casting is completed. Compared with the prior art, the method has the following advantage that through scientifically proportioning the content of each element, refining process of a refining agent is omitted, the fluidity of the materials is improved by introducing nitrogen, the problem that the casting performance is lowered due to the content of silicon is solved, addition of dysprosium can effectively reduce the microporous rate of the alloy, surface tension of the alloy during the casting process is improved, and the mechanical properties of the alloy are improved.

Owner:安徽玉成光华铝业有限公司

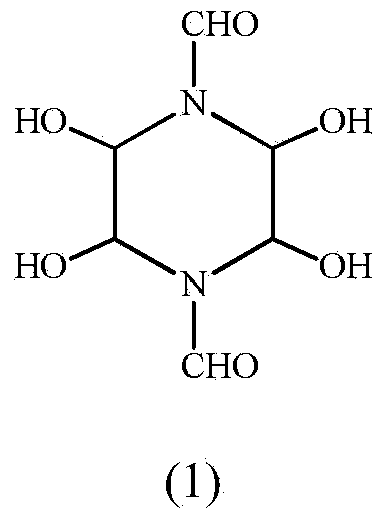

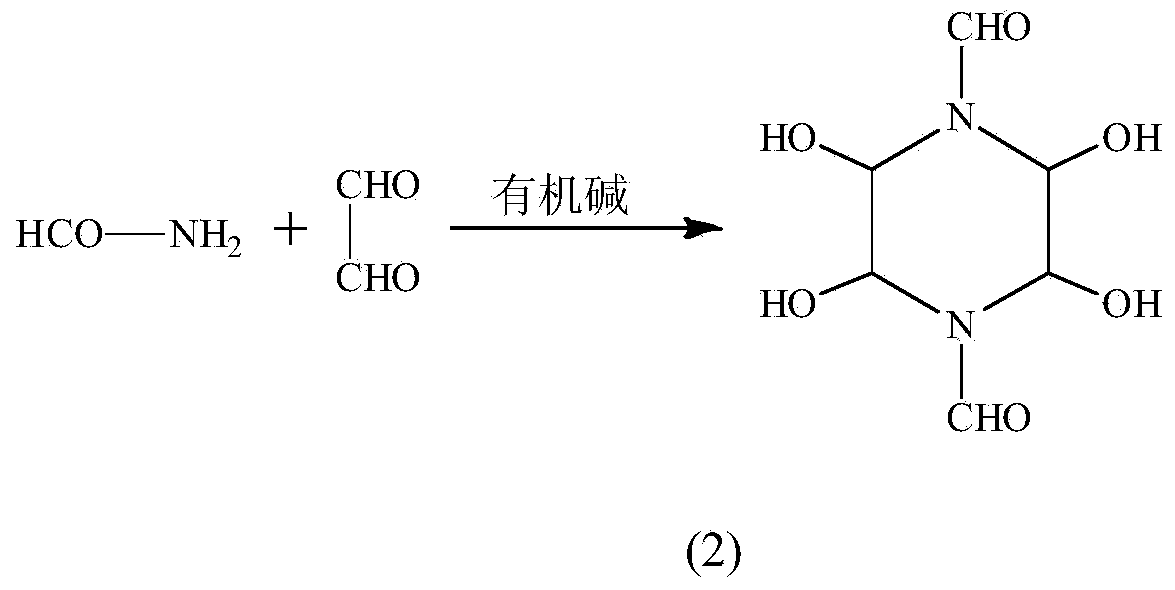

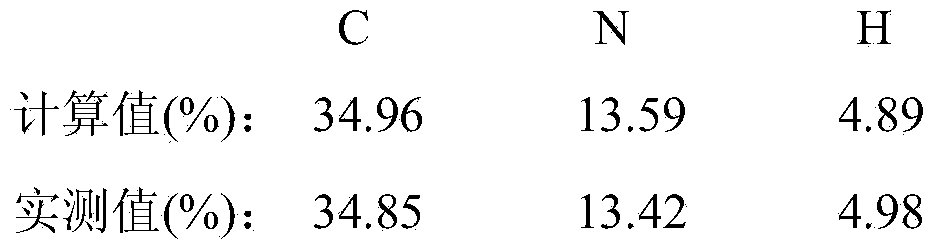

Synthetic method of 1,4-diformyl-2,3,5,6-tetrahydroxypiperazine

InactiveCN104262266AShort synthesis reaction timeEliminate the refining processOrganic chemistryOrganic solventGlyoxal

The invention discloses a synthetic method of 1,4-diformyl-2,3,5,6-tetrahydroxypiperazine. The 1,4-diformyl-2,3,5,6-tetrahydroxypiperazine is shown in structural formula in the specification. The synthetic method comprises the following steps: adding glyoxal aqueous solution and formamide in a reaction vessel according to the molar ratio of 1: (0.5-2), stirring and fully mixing; dropwise adding organic alkali in which the molar ratio of water to glyoxal is 100: (6-15), controlling the temperature within 30-60 DEG C and immediately generating white precipitates after the completion of dropwise adding within 5-10 minutes, filtering, washing the precipitates with water and an organic solvent and drying to obtain the 1,4-diformyl,3,5,6-tetrahydroxypiperazine. The synthetic method is used for the preparation of the 1,4-diformyl-2,3,5,6-tetrahydroxypiperazine.

Owner:XIAN MODERN CHEM RES INST

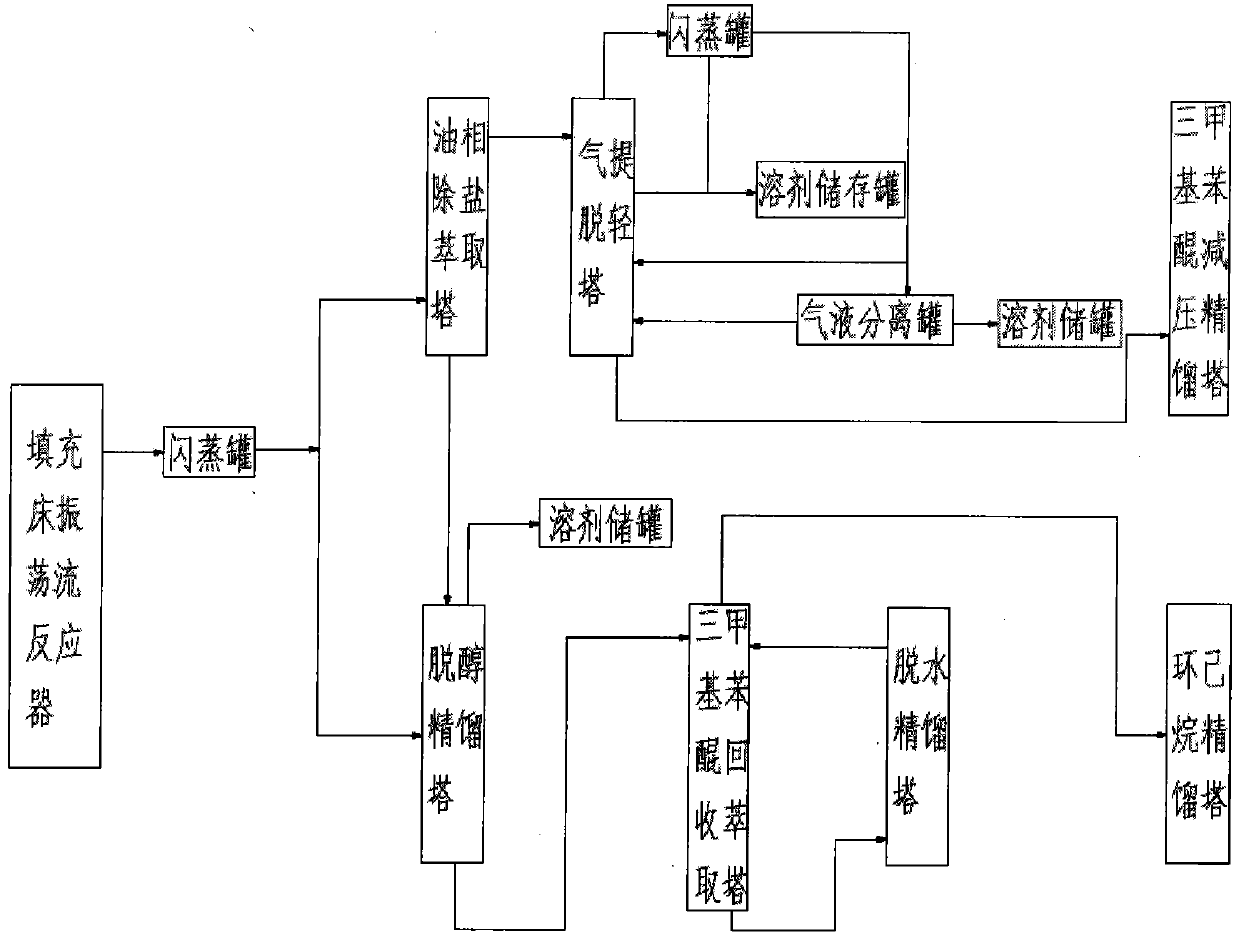

A kind of method for continuously preparing 2,3,5-trimethylbenzoquinone

ActiveCN104557502BLow selectivityReduce the risk of explosionQuinone preparation by oxidationQuinone separation/purificationPtru catalystOil phase

The invention discloses a method for continuously preparing 2,3,5-trimethylquinone. The method comprises a reaction process, an oil phase refining process and a water phase refining process. The reaction process comprises the following steps: a reaction raw material and a catalyst are in oxidizing reaction in a packed bed oscillatory flow reactor to obtain an oil phase and a water phase mainly comprising 2,3,5-trimethylquinone; the oil phase refining process comprises the following steps: the oil phase after the reaction passes through an oil phase desalting extracting tower and a gas stripping light component removal tower and then passes through a decompression rectifying tower to obtain a 2,3,5-trimethylquinone product at the tower top; the water phase refining process comprises the following steps: a water phase material sequentially passes through a dealcoholization rectifying tower, a recycling extracting tower and a cyclohexane rectifying tower to obtain 2,3,5-trimethylquinone. With adoption of the method, the continuity of reaction and separation process of 2,3,6-trimethylphenol is realized, and the problems that the production efficiency is low, the operating strength is high, the product quality is not stable, and the process potential safety hazard is large are solved.

Owner:吴嘉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com