Method for producing strontium-silicon alloy by utilizing high-purity ferrosilicon powder

A technology of high-purity silicon powder and ferrosilicon, which is applied in the field of smelting, can solve the problems of high labor intensity, complicated manufacturing path, increased equipment and auxiliary material costs, etc., to improve the total recovery rate of the alloy, improve the furnace operation rate, save The effect of de-refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

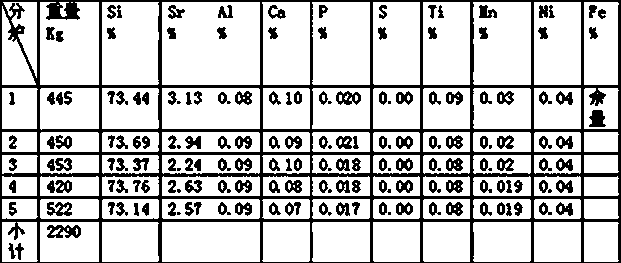

Examples

Embodiment Construction

[0017] This patent provides a variety of parallel schemes, and the different expressions belong to the improved scheme based on the basic scheme or the parallel scheme. Each scheme has its own unique characteristics.

[0018] Main raw materials and requirements: high-purity silicon powder: SI 73-75%, Al, Ca99%, Chongqing Yuanhe Metal Company.

[0019] Main equipment: 1000Kg medium frequency induction furnace and related tapping equipment

[0020] Tools: slag skimmer, slag cleaning shovel, shovel, 330 thermometer, stirrer, some steel brazing, X-ray fluorescence spectrometer and related laboratory equipment.

[0021] 1. Raw material preparation: Calculate the amount of raw materials based on 450Kg of alloy per furnace, in which the yield of high-purity silicon powder alloy is 90-98%, and the yield of strontium metal is 75-90%, and the slag remover is calculated based on the slag-iron ratio of 3-5%. , delivered to the operating platform after measurement.

[0022] 2. High-puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com