Preparation method of rubber vulcanizing accelerator TBBS

A technology of rubber vulcanization and accelerator, applied in the field of preparation of rubber additives, can solve the problems of not being able to fundamentally solve the problem of waste water, increasing cost, not mentioning the recovery of decoking agent, etc., so as to reduce process safety risks and environmental problems. The effect of low pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

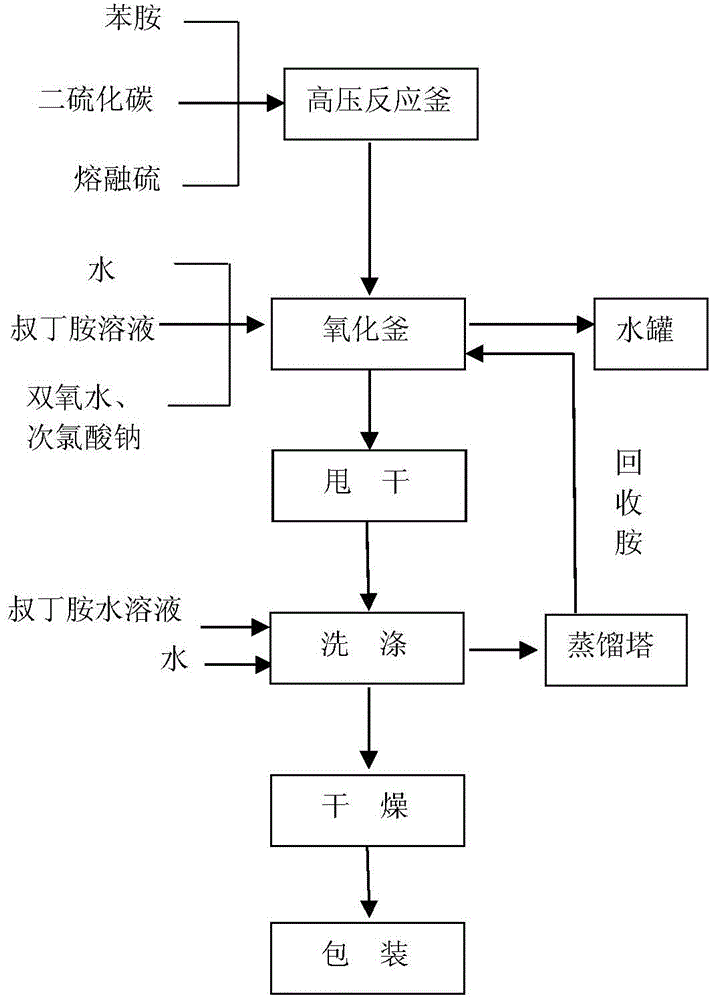

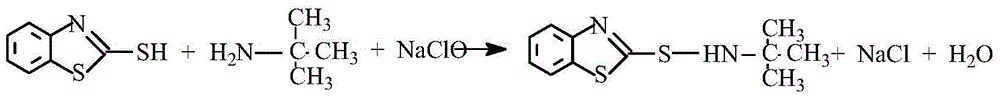

Method used

Image

Examples

Embodiment 1

[0019] (1) Crude product of synthetic accelerator MBT: 400 kg of aniline, 137.6 kg of molten sulfur obtained from the Claus process, and 326.9 kg of carbon disulfide were respectively put into an autoclave. The reaction temperature is 250°C, the final pressure is 9.05MPa, and the crude product of rubber accelerator MBT is synthesized after reaction for 5 hours. The crude MBT content is more than 90%.

[0020] (2) utilize crude product MBT to prepare accelerator TBBS:

[0021] A. Dispersion: Put 3.6t of water into the oxidation kettle and start stirring. The crude product M was transported to the oxidation kettle, stirred for 0.5 h, and the temperature was lowered to obtain the crude product MBT with a smaller particle size. Water was vented from the reaction kettle.

[0022] B. Oxidation: Add 5231kg of 30% tert-butylamine into the oxidation kettle. After mixing evenly, add hydrogen peroxide oxidant dropwise, the concentration of hydrogen peroxide is 5%. The oxidation te...

Embodiment 2

[0025] (1) Crude product of synthetic accelerator MBT: 400 kg of aniline, 165.2 kg of molten sulfur obtained from the Claus process, and 490 kg of carbon disulfide were respectively put into an autoclave. The reaction temperature is 260°C, the final pressure is 11MPa, and the crude product of rubber accelerator MBT is synthesized after reaction for 3 hours. The crude MBT content is more than 90%.

[0026] (2) utilize crude product MBT to prepare accelerator TBBS:

[0027] A. Dispersion: Put 7.2t of water into the oxidation kettle and start stirring. The crude product M was transported to the oxidation kettle, stirred for 1 hour, and the temperature was lowered to obtain the crude product MBT with a smaller particle size. Water was vented from the reaction kettle.

[0028] B. Oxidation: Add 6277kg of 50% tert-butylamine into the oxidation kettle. After mixing evenly, add hydrogen peroxide oxidant dropwise, the concentration of hydrogen peroxide is 10%. The oxidation temper...

Embodiment 3

[0031] (1) Crude product of synthetic accelerator MBT: 400 kg of aniline, 151.4 kg of molten sulfur obtained from the Claus process, and 393 kg of carbon disulfide were respectively put into an autoclave. The reaction temperature is 280°C, the final pressure is 9.8MPa, and the crude product of rubber accelerator MBT is synthesized after reaction for 4 hours. The crude MBT content is more than 90%.

[0032] (2) utilize crude product MBT to prepare accelerator TBBS:

[0033] A. Dispersion: Put 5t of water into the oxidation kettle and start stirring. The crude product M was transported to the oxidation kettle, stirred for 2 hours, and the temperature was lowered to obtain the crude product MBT with a smaller particle size. Water was vented from the reaction kettle.

[0034] B. Oxidation: Add 5492kg of 40% tert-butylamine into the oxidation kettle. After mixing evenly, add hydrogen peroxide oxidant dropwise, the concentration of hydrogen peroxide is 7%. The oxidation tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com