Casting high ferrochrome or casting high chromium steel roll for welding steel pipe

A technology for welding steel pipes and high-chromium iron, which is applied in the field of casting rolls, can solve the problems of poor performance and use effect, low wear resistance, long process flow, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

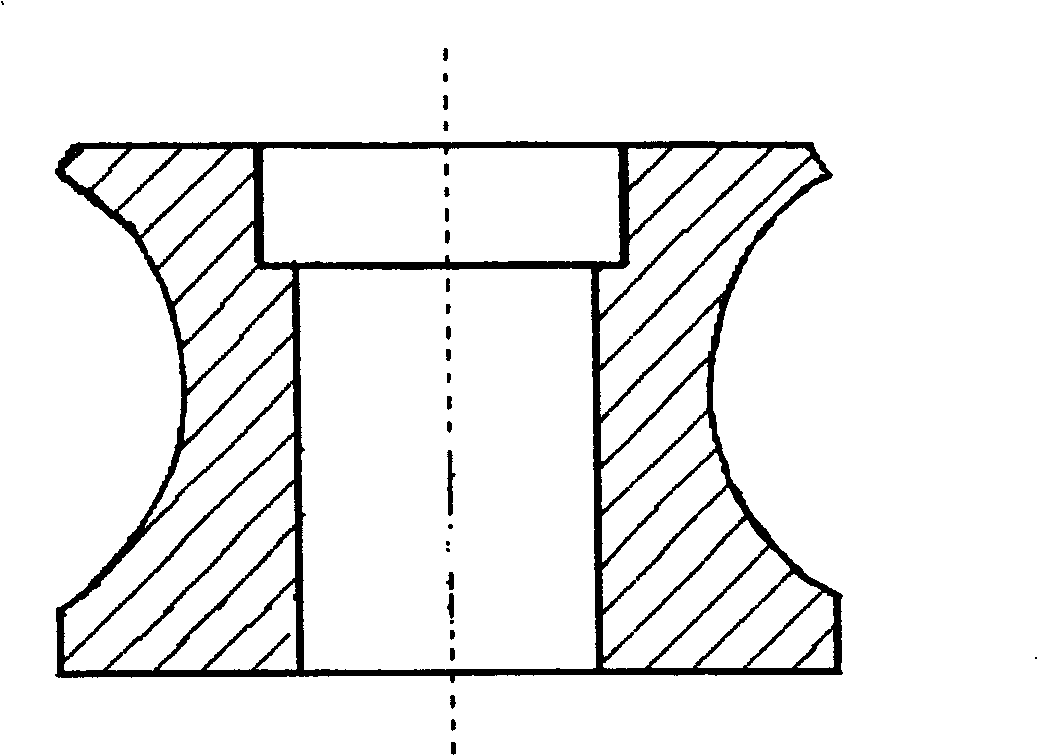

[0028] refer to figure 1 As shown, in this embodiment, according to the application of cast high-chromium iron or cast high-chromium steel rolls to rolling mills for rolling welded steel pipes according to the present invention, a set of 2 pieces of Φ530.0 welded Side extrusion rolls for steel pipes, the composition of which is selected from the following high-chromium iron components (by weight): C: 1.8%, Si: ≤1.0%, Mn: ≤1.0%, P: ≤0.05%, S: ≤0.05% , Cr: 13%, Ni: 1.0%, Mo: 1.2%, Ti: 0.2%, V: 0.2%, Cu: 0.5%, RE: 0.05%, and the rest is Fe. The hardness after heat treatment in this embodiment is HRC58-59.8.

[0029] Select the ratio of raw materials according to the composition requirements, melt and cast in an intermediate frequency induction furnace to obtain the required blank, and then perform heat treatment, turning, grinding and other processing to manufacture side extrusion rolls for welded steel pipes.

[0030]The side extrusion roll for the welded steel pipe of the pre...

Embodiment 2

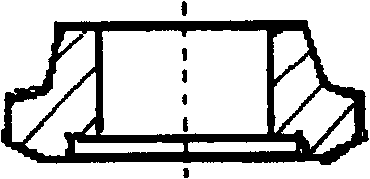

[0032] Implementation 2 is shaped like figure 2 shown. According to the purpose of the present invention, a set of 2 pieces of Φ273.1 welded steel pipes has been manufactured by the casting production process, and its composition is selected from the following high-chromium steel composition (in weight percentage): C: 0.9%, Si : ≤1.0%, Mn: ≤1.0%, P: ≤0.05%, S: ≤0.05%, Cr: 10%, Ni: 0.5%, Mo: 0.8%, Ti: 0.3%, V: 0.5%, W: 0.3%, RE: 0.015%, the rest is Fe.

[0033] Select the ratio of raw materials according to the composition requirements, melt and cast in a medium frequency induction furnace to obtain the required blank, and then perform heat treatment, turning, grinding and other processing to manufacture welded steel pipes with extrusion rolls.

[0034] Example 2 is an upper extrusion roll for welded steel pipes, the weight of the blank is 91.6kg / piece, the weight of the finished product is 65.5kg / piece, and the material utilization rate is 71.5%. In this embodiment, if the...

Embodiment 3

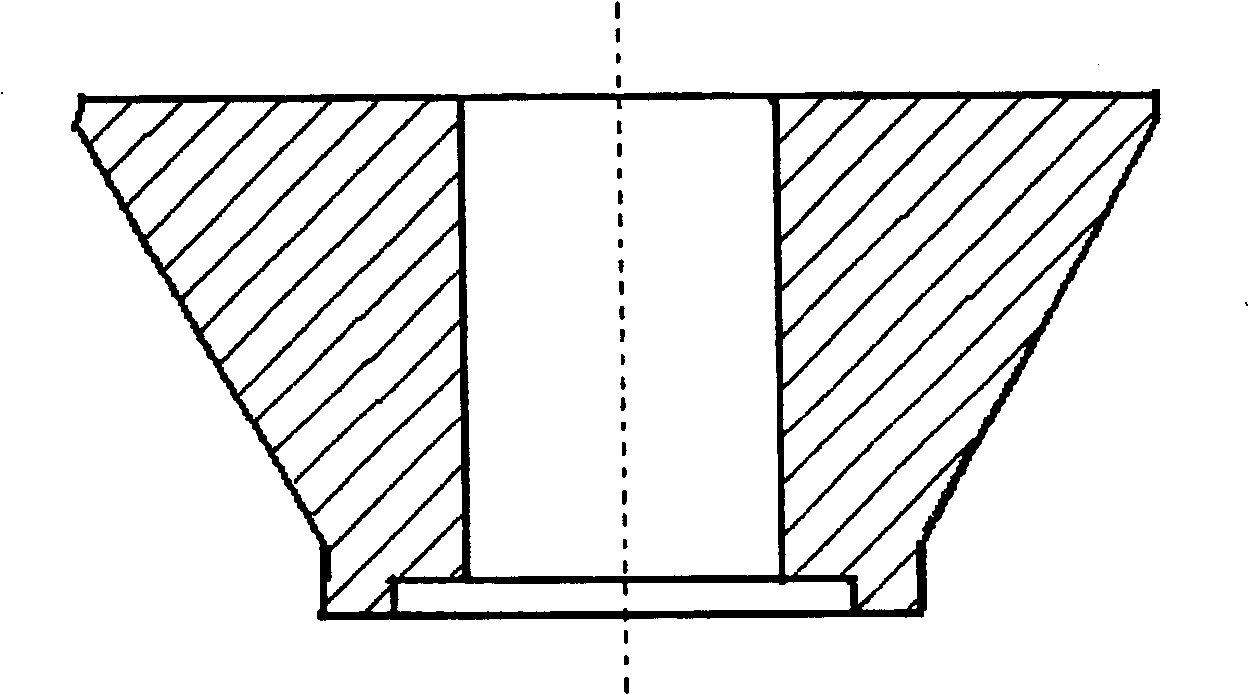

[0036] Implementation 3 is shaped like image 3 shown. According to the purpose of the present invention, a set of 2 pieces of 500 * 500mm welded rectangular steel pipes has been manufactured with the casting production process, and its composition is selected from the following high-chromium iron composition (in weight percent): C: 2.8%, Si: ≤1.0%, Mn: ≤1.0%, P: ≤0.05%, S: ≤0.05%, Cr: 22%, Ni: 2.5%, Mo: 2.0%, Ti: 0.1%, V: 0.3%, Cu: 0.5 %, RE: 0.1%, the rest is Fe.

[0037] Select the ratio of raw materials according to the composition requirements, melt and cast in an intermediate frequency induction furnace to obtain the required blank, and then perform processing such as turning and grinding to produce the lower roll for welding rectangular steel pipes.

[0038] Embodiment 3 is a lower roll for welding rectangular steel pipes of 500×500mm, the blank weight is 3513kg / piece, the finished product weight is 2780kg / piece, and the material utilization rate is 79.1%. The roll h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com