Preparation method of rubber vulcanization accelerator DCBS

A rubber vulcanization and accelerator technology, applied in organic chemistry and other fields, can solve problems such as environmental hazards, high raw material costs, and unqualified product quality, and achieve the effects of low environmental pollution, low cost, and reduction of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

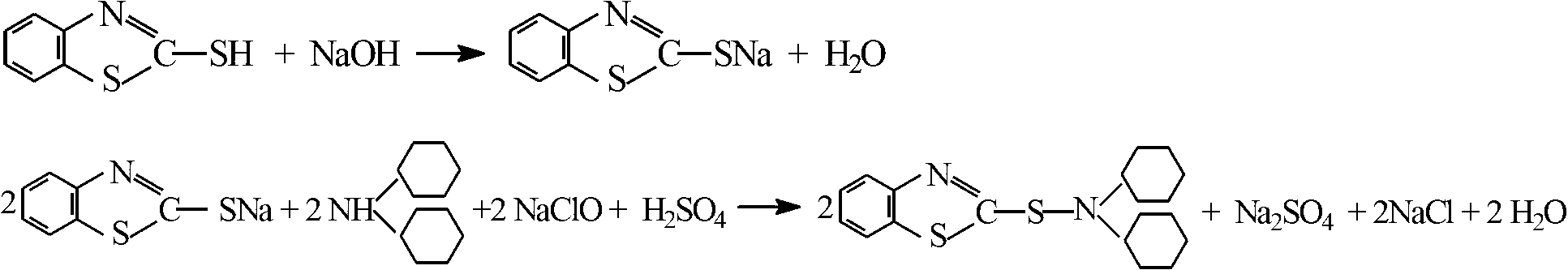

Method used

Image

Examples

Embodiment 1

[0030] Add 100g of crude MBT obtained from the high pressure reaction (measured MBT purity is 89.0%, mass percentage) directly into a container containing 44.5g of water (the weight ratio of water to purified MBT is 0.5:1) under stirring , add dropwise the sodium hydroxide aqueous solution of mass content 20% in the container, maintain the pH value in the container at 9.5, MBT is all dissolved and made M-Na salt solution, after the sodium hydroxide aqueous solution consumes 74.5g, the pH of the reactant Keep 9.5 unchanged within 30 minutes, and transfer the supernatant to the metering tank after standing;

[0031] 1780g of isopropanol (the weight ratio of isopropanol to MBT (after conversion) is 20:1) and 96.5g of dicyclohexylamine (the molar ratio of dicyclohexylamine to MBT (after conversion) is 1 : 1) The sodium hypochlorite solution with 12% available chlorine, M-Na salt solution, and 20% sulfuric acid solution are added dropwise in the container at the same time. During t...

Embodiment 2

[0033] Add 100g of crude MBT obtained from the high pressure reaction (measured MBT purity is 89.0%, mass percentage content) directly into a container containing 89g of water (the weight ratio of water to crude MBT is 1:1) under stirring, and pour into the container Add an aqueous sodium hydroxide solution with a mass content of 20% dropwise to maintain the pH value in the container at 9.5, so that MBT is completely dissolved to make a M-Na salt solution. After the aqueous sodium hydroxide solution consumes 75.3g, the pH of the reactant is within 30min Keep 9.5 unchanged, and transfer the supernatant to the metering tank after standing;

[0034] 1780 g of isopropanol (the weight ratio of isopropanol to MBT (after conversion) is 20:1) and 96.5 g of dicyclohexylamine (the molar ratio of dicyclohexylamine to MBT (after conversion) is 1 : 1) The sodium hypochlorite solution with 12% available chlorine, M-Na salt solution, and 25% sulfuric acid solution were added dropwise in the ...

Embodiment 3

[0036] The crude MBT 100g obtained by the high pressure reaction (measured MBT purity is 89.0%, mass percentage content) is directly added to the container containing 53.4g water (the weight ratio of water and crude MBT is 0.6:1) under stirring, Add dropwise sodium hydroxide aqueous solution with a mass content of 40% in the container to maintain the pH value in the container at 9.5, so that MBT is completely dissolved to make M-Na salt solution. After 85.5 g of sodium hydroxide aqueous solution is consumed, the pH of the reactant is 30 minutes Keep 9.5 unchanged, and after standing, transfer the supernatant to the metering tank;

[0037] 1780g of isopropanol (the weight ratio of isopropanol to MBT (after conversion) is 20:1) and 96.5g of dicyclohexylamine (the molar ratio of dicyclohexylamine to MBT (after conversion) is 1 :1) Add sodium hypochlorite solution with 12% available chlorine, M-Na salt solution, and 20% sulfuric acid solution dropwise in the container at the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com