Method for production of potassium sulfate from industrial by-product ammonium sulfate

A technology of ammonium sulfate and by-products, applied in the direction of sulfate/bisulfate preparation, etc., can solve the problems of ammonium sulfate difficult to handle, chemical fertilizer potassium sulfate production process complex, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

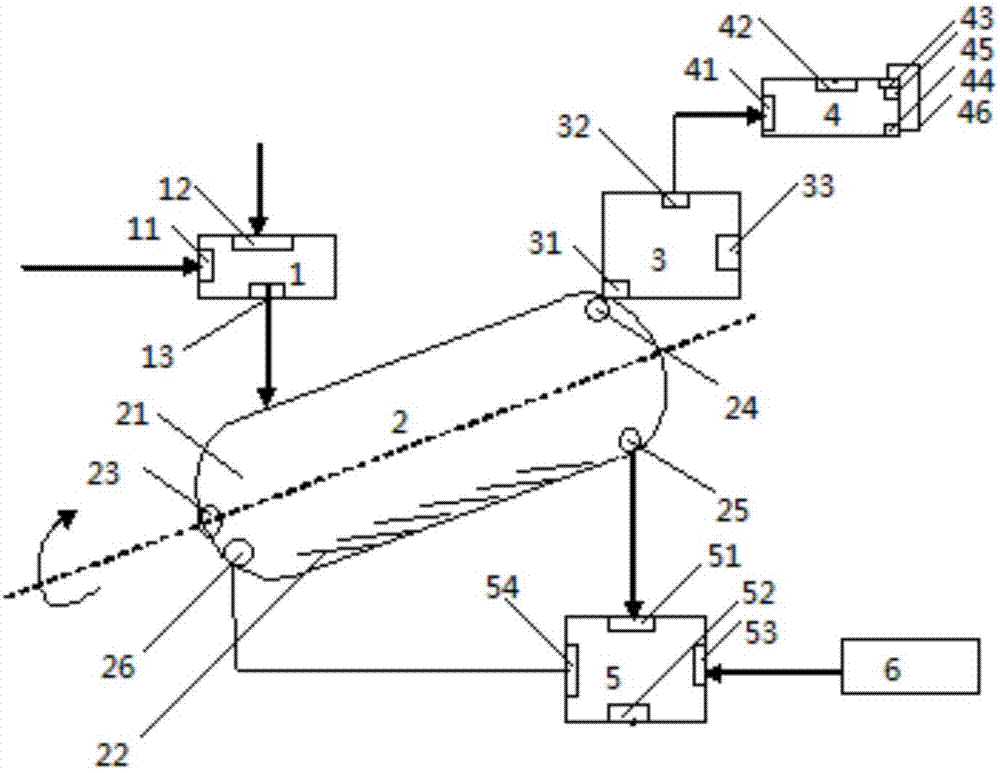

Image

Examples

Embodiment 1

[0107] 2000kg of ammonium sulfate (a by-product of the preparation of methyl methacrylate, wherein the water content is 10%, containing 0.8% of organic impurities) and 2054kg of potassium chloride (purity 98.0%) are stirred and mixed, mixed for 2.0h, and put into a high-temperature reactor , at 400°C, roasted at 60rpm (stirring speed) for 2.0h, at the same time, feed 20°C air into the high temperature reactor, the air flow rate is 6m 3 / h, the solid product after roasting is recovered after being cooled by a potassium sulfate cooler, and the gaseous product after roasting is fixed through a gas trap, wherein the potassium sulfate product is calculated by the weight of potassium element, and the recovery rate of potassium is 98.5%. The purity of the obtained potassium sulfate is 98.7%, which meets agricultural needs; the ammonium chloride product is based on the weight of nitrogen, and the recovery rate of ammonium is 98%, and the purity of ammonium chloride is 98.0%. Compared ...

Embodiment 2

[0110] 2000kg of ammonium sulfate (a by-product of the preparation of methyl methacrylate, wherein the water content is 12%, containing 1.2% of organic impurities) and 1999kg of potassium chloride (purity 98.0%) are stirred and mixed, mixed for 1.5h, and put into a high-temperature reactor , at 420°C, roasting at 40rpm (stirring speed) for 3.0h, at the same time, feed 20°C air into the high temperature reactor, the air flow rate is 10m 3 / h, the solid product after roasting is recovered after being cooled by a potassium sulfate cooler, and the gaseous product after roasting is fixed through a gas trap, wherein the potassium sulfate product is calculated by the weight of potassium element, and the recovery rate of potassium is 98.8%. The purity of the obtained potassium sulfate is 98.5%, which meets agricultural needs; the ammonium chloride product is based on the weight of nitrogen, and the recovery rate of ammonium is 97.8%, and the purity of ammonium chloride is 98.4%. Calcul...

Embodiment 3

[0113] 2000kg of ammonium sulfate (a by-product of the preparation of methyl methacrylate, wherein the water content is 5%, containing 0.5% of organic impurities) and 2176kg of potassium chloride (purity 98.0%) are stirred and mixed, mixed for 1.5h, and put into a high-temperature reactor , at 300°C, roasting at 60rpm (stirring speed) for 2.5h, at the same time, feed 20°C air into the high temperature reactor, the air flow rate is 2m 3 / h, the solid product after roasting is recovered after being cooled by a potassium sulfate cooler, and the gaseous product after roasting is fixed through a gas trap, wherein the potassium sulfate product is calculated by the weight of potassium element, and the recovery rate of potassium is 98.9%. The purity of the obtained potassium sulfate is 98.0%, which meets agricultural needs; the ammonium chloride product is based on the weight of nitrogen, and the recovery rate of ammonium is 95.8%, and the purity of ammonium chloride is 98.2%. Compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com