Composite solvent for purifying acetylene and purification method thereof

A composite solvent and acetylene technology, applied in chemical instruments and methods, hydrocarbons, organic chemistry, etc., can solve the problem of large solvent loss, achieve high selectivity, mild absorption and desorption operating conditions, and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

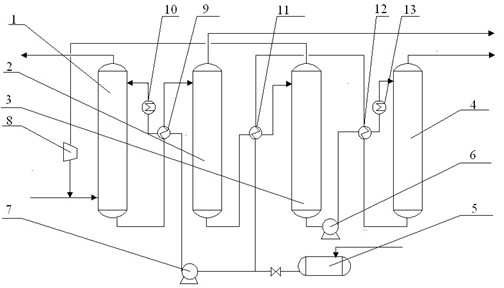

Method used

Image

Examples

example 1

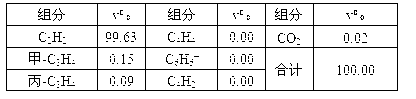

[0017] The composition of the acetylene raw material gas is shown in Table 1. The physical solvent in the composite solvent is 25% NMP, 40% ethylene glycol, and 10% diethylene glycol. 2 The chemical auxiliary agent is 7% diethanolamine, 8% polyethylene glycol dimethyl ether, the polymerization inhibitor is 5% phenol, and the corrosion inhibitor is 5% diethylenetriamine. The operating parameters of each tower in the purification process are shown in Table 2. The composition of the refined acetylene product obtained after purification is shown in Table 3.

[0018] Table 2 Operating parameters of each column

[0019]

[0020] Table 3 Composition of refined acetylene products

[0021]

[0022] Acetylene product concentration is 99.54%, CO 2 The removal rate was 99.05%, and the removal rate of higher alkynes was 90.35%.

example 2

[0024] The composition of the acetylene raw material gas is shown in Table 1. The physical solvent in the composite solvent used is 45% DMF, 20% dimethyl sulfoxide, and 20% diethylene glycol. 2 The chemical additives are 5% monoethanolamine and 5% ethylenediamine, the polymerization inhibitor is 1% phenylenediamine and 2% tert-butylcatechol, and the corrosion inhibitor is 2% aniline. The operating parameters of each tower are shown in Table 4, and the composition of the refined acetylene product obtained after purification is shown in Table 5.

[0025] Table 4 Operating parameters of each column

[0026]

[0027] Table 5 Composition of refined acetylene products

[0028]

[0029] Acetylene product concentration is 99.63%, CO 2 The removal rate is 99.72%, and the removal rate of higher alkynes is 94.67%.

example 3

[0031] The composition of the acetylene raw material gas is shown in Table 1. The physical solvent in the composite solvent used is 50% dimethyl sulfoxide and 32% ethylene glycol. 2 The chemical auxiliary agent is 12% polyamine, the polymerization inhibitor is 3% benzoquinone, and the corrosion inhibitor is 3% picoline. The operating parameters of each tower are shown in Table 6, and the composition of the refined acetylene product obtained after purification is shown in Table 7.

[0032] Table 6 Operating parameters of each column

[0033]

[0034] Table 7 Composition of refined acetylene products

[0035]

[0036] Acetylene product concentration is 99.72%, CO 2 The removal rate is 100%, and the removal rate of higher alkynes is 92.38%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com