Novel continuous production method of phenylenediamine

A production method and technology of phenylenediamine, applied in chemical instruments and methods, preparation of organic compounds, preparation of nitro compounds, etc., can solve the problems of high energy consumption, cumbersome process, damaged yield, etc., and achieve reduction of reaction steps , Simplify production procedures and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

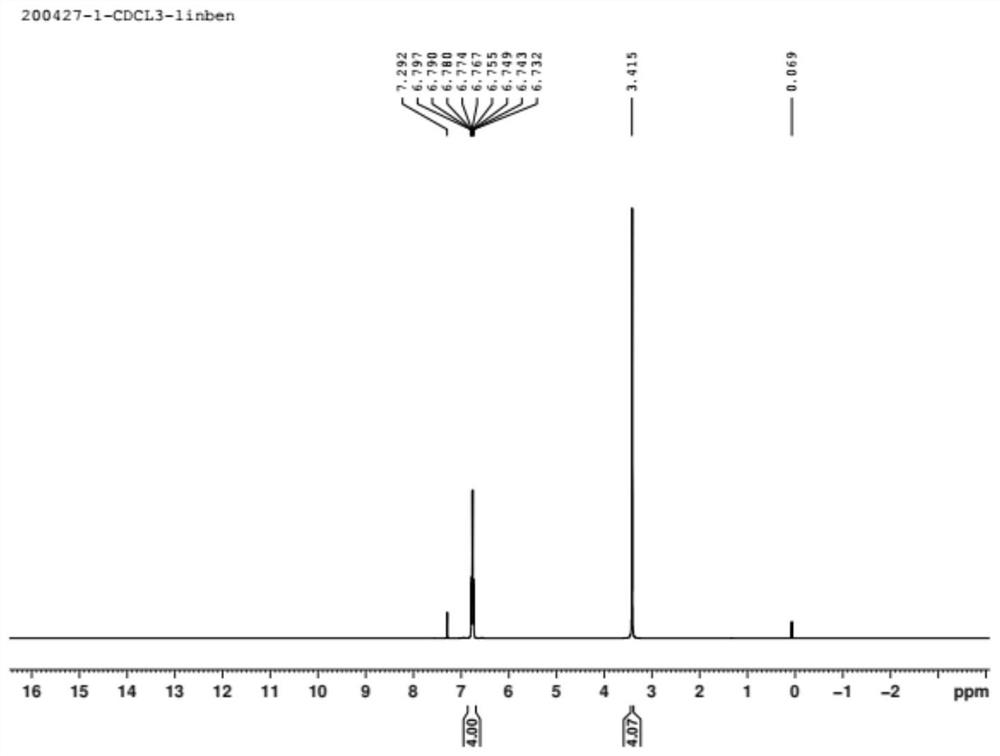

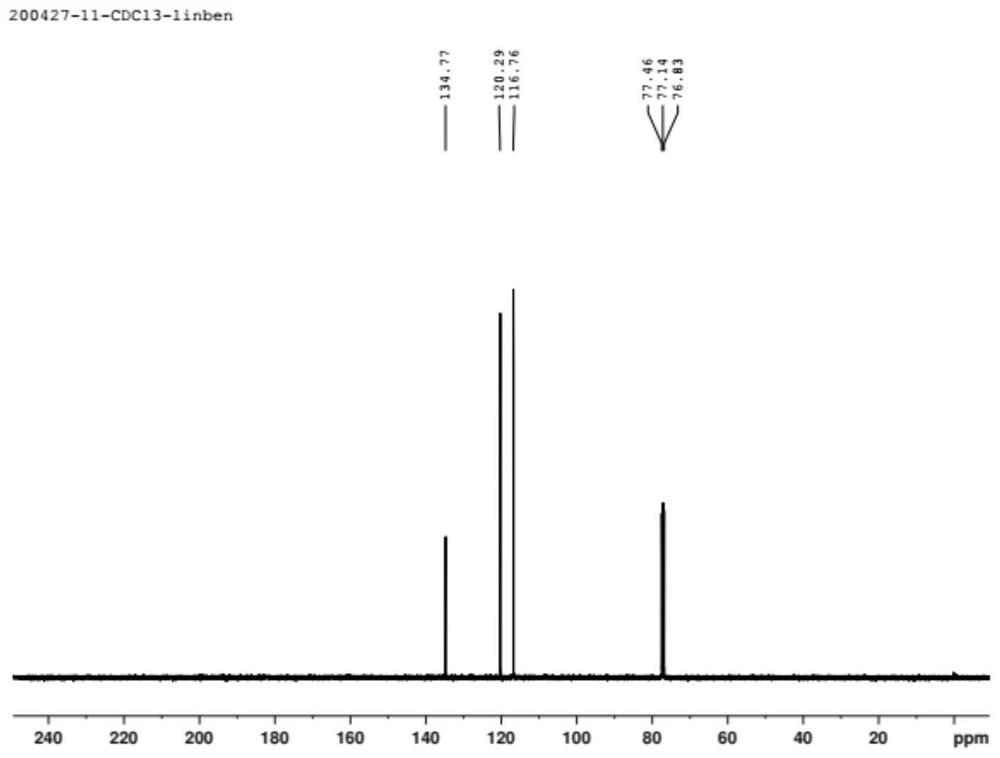

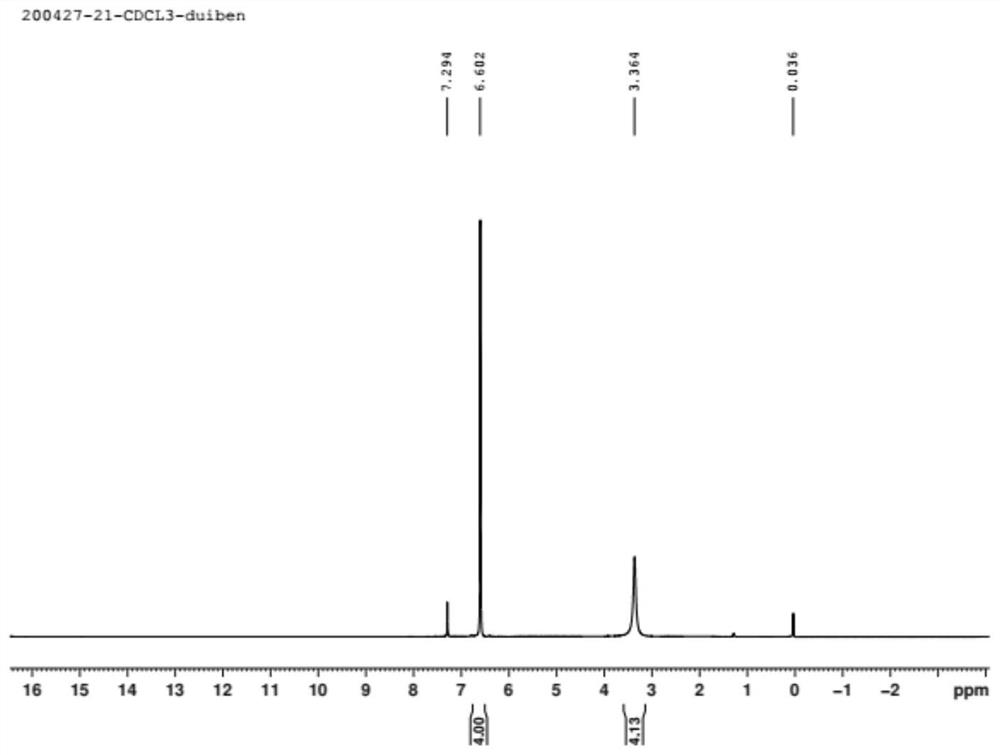

Image

Examples

Embodiment 1

[0063] Prepare mixed acid according to the volume ratio of concentrated nitric acid and concentrated sulfuric acid as 1.2:1, then the mixed acid and chlorobenzene are continuously entered into 1# nitration pot according to the molar ratio of chlorobenzene and nitric acid as 1:1.05, and nitrated at 50-55°C for 40 minutes, and react The material overflows to 2# nitration pot, and continues to react at 60-65°C for 40 minutes, then enters 3# nitration pot, and reacts at 70-75°C for 40 minutes. After the reaction is completed, the material is discharged, neutralized and washed with water to obtain mixed nitrochlorobenzene;

[0064] Mix nitrochlorobenzene directly with ammonia water for ammonolysis, the mass ratio of mixed nitrochlorobenzene and 35% ammonia water is 1:3.5, heat up to 180°C, keep the reaction for 10 hours under 45kg atmospheric pressure (about 45MPa), and then cool down The material was filtered and washed with ice water to obtain mixed nitroanilines.

[0065] The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com