A kind of smelting production method of titanium microalloyed low-cost q355b steel plate

A Q355B, micro-alloying technology, applied in the field of iron and steel metallurgy, can solve the problems of long processing time, reduced production efficiency, low titanium yield, etc., and achieve the effect of improving the purity of molten steel, reducing process costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail with a specific embodiment below.

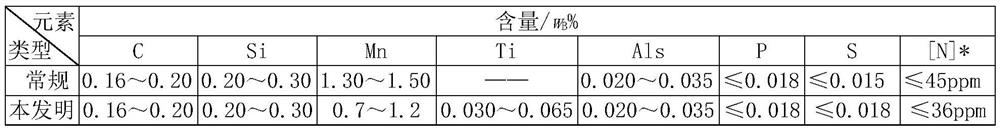

[0051] Based on a 180t top-bottom combined blowing converter in a steel plant, Q355B low-alloy structural steel continuous casting slabs are produced based on the converter smelting-argon station treatment-slab continuous casting process. percentage:

[0052] 1) Raw material requirements

[0053] The amount of molten iron is 160-170t, and the phosphorus content of the molten iron is ≤0.12%. The molten iron is desulfurized by KR pretreatment. After desulfurization, the sulfur content of the molten iron is ≤30ppm. The temperature of the molten iron is ≥1280°C before it is blended into the converter. First, 15-20t of low-sulfur scrap steel is blended into the furnace, and then the molten iron is blended. Due to the subsequent cancellation of LF treatment, the purpose of deep desulfurization of molten iron and adding low-sulfur scrap steel is to control the sulfur content of fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com