Method for adding grain refinement element Ti into cast aluminum silicon alloy

A technology for casting aluminum-silicon alloys and grain refinement, which is applied in the field of metallurgy, can solve problems such as undiscovered patent documents, achieve excellent refining and refining effects, improve quality, and simplify the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

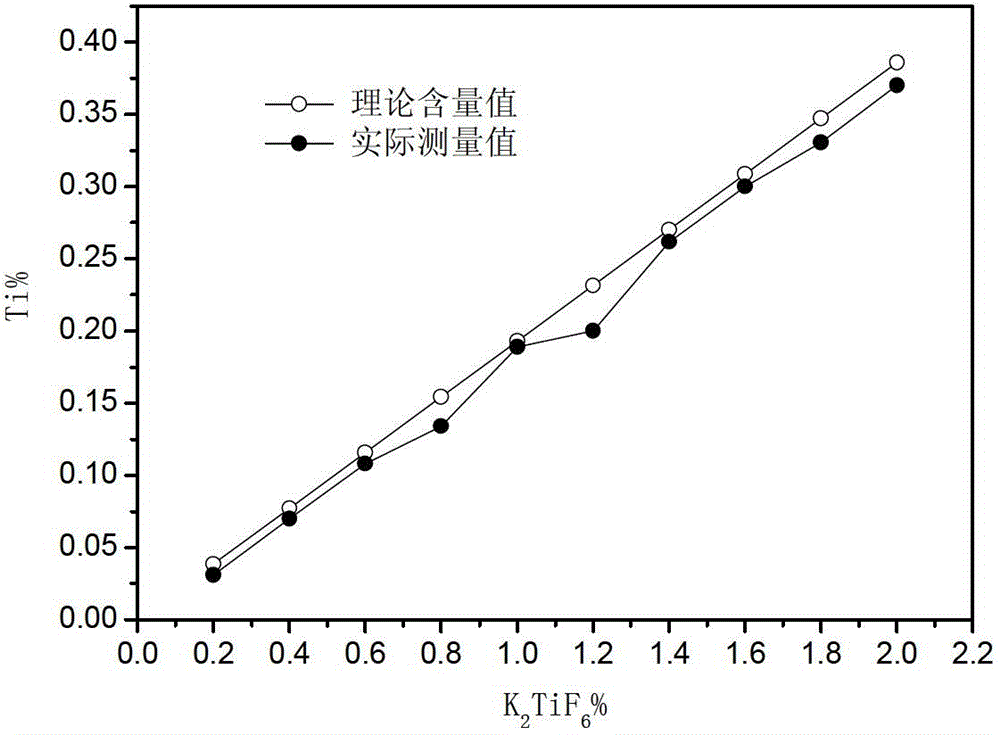

[0023] A method for introducing grain refinement element Ti into a cast aluminum-silicon alloy, the refiner adopts potassium fluorotitanate powder, and the cast aluminum-silicon alloy is A356.2, the steps are:

[0024] ⑴The total feed is 15T, according to the internal control requirements of the composition of A356.2 alloy liquid, the required range of Ti content is: 0.08-0.15%, the Ca element is less than 0.003%; according to the content of 0.12% Ti content, weigh K 2 The mass of TiFx is 93kg;

[0025] (2) Put the weighed potassium fluorotitanate in a constant temperature preheating drying oven at 300°C and dry for 2 hours;

[0026] (3) Add aluminum ingots and metal silicon for remelting into the melting furnace, ignite and heat up, and control the melting temperature between 740 and 780 °C;

[0027] ⑷After the aluminum ingots and metal silicon for remelting are completely melted, metal magnesium is added, and the components are tested after fully stirring;

[0028] ⑸Except...

Embodiment 2

[0035] A method for introducing grain refinement element Ti into a cast aluminum-silicon alloy, the refiner adopts potassium fluorotitanate powder, and the cast aluminum alloy is AS7G03, the steps are:

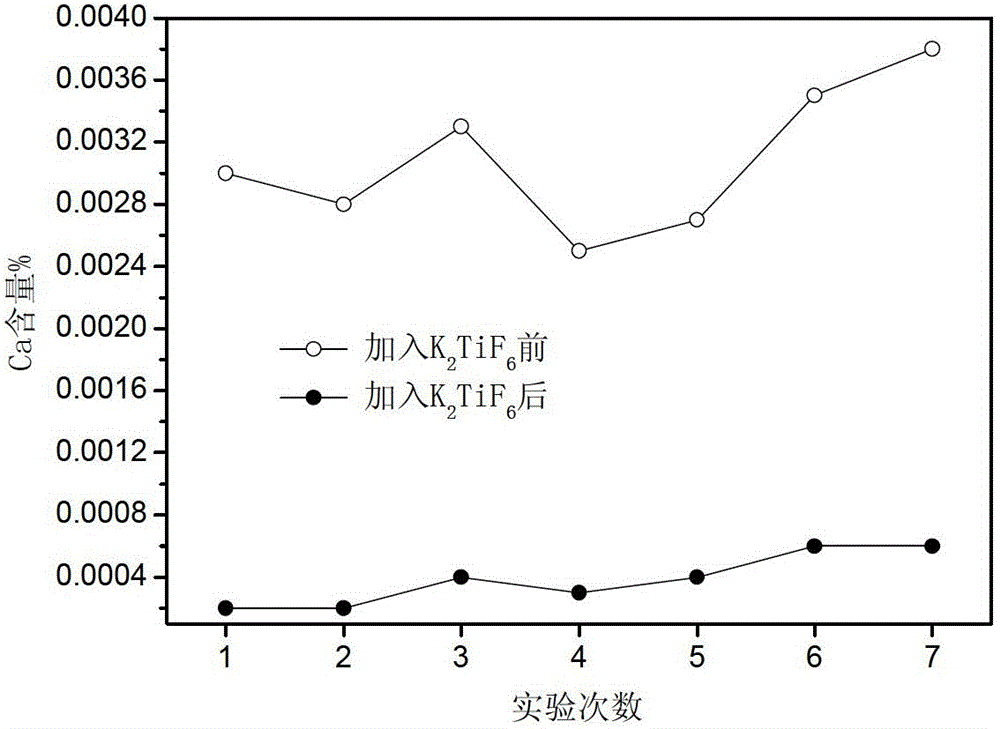

[0036] ⑴The total feeding is 20T, according to the composition internal control requirements of AS7G03 alloy, the required range of Ti content is: 0.10~0.16, the Ca element is less than 0.0018%; according to the content of Ti 0.14, weigh K 2 TiF 6 The mass is 145kg;

[0037] (2) Put the weighed potassium fluotitanate in a constant temperature preheating drying oven at 250°C and dry for 2.5 hours;

[0038] (3) Add aluminum ingots and metal silicon for remelting into the melting furnace, ignite and heat up, and control the melting temperature between 750 and 770°C;

[0039] (4) After the aluminum ingots and metal silicon for remelting are completely melted, add intermediate alloys or pure metals of other elements except titanium, and carry out component detection after fully s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com