Gear engine and drive system

A technology of engines and gears, applied in the field of engine systems, can solve the problems of easy evaporation of liquid, lower engine efficiency, and easy generation of back pressure, etc., to achieve high speed and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The real-time mode of the present invention will be described in detail below in conjunction with the accompanying drawings.

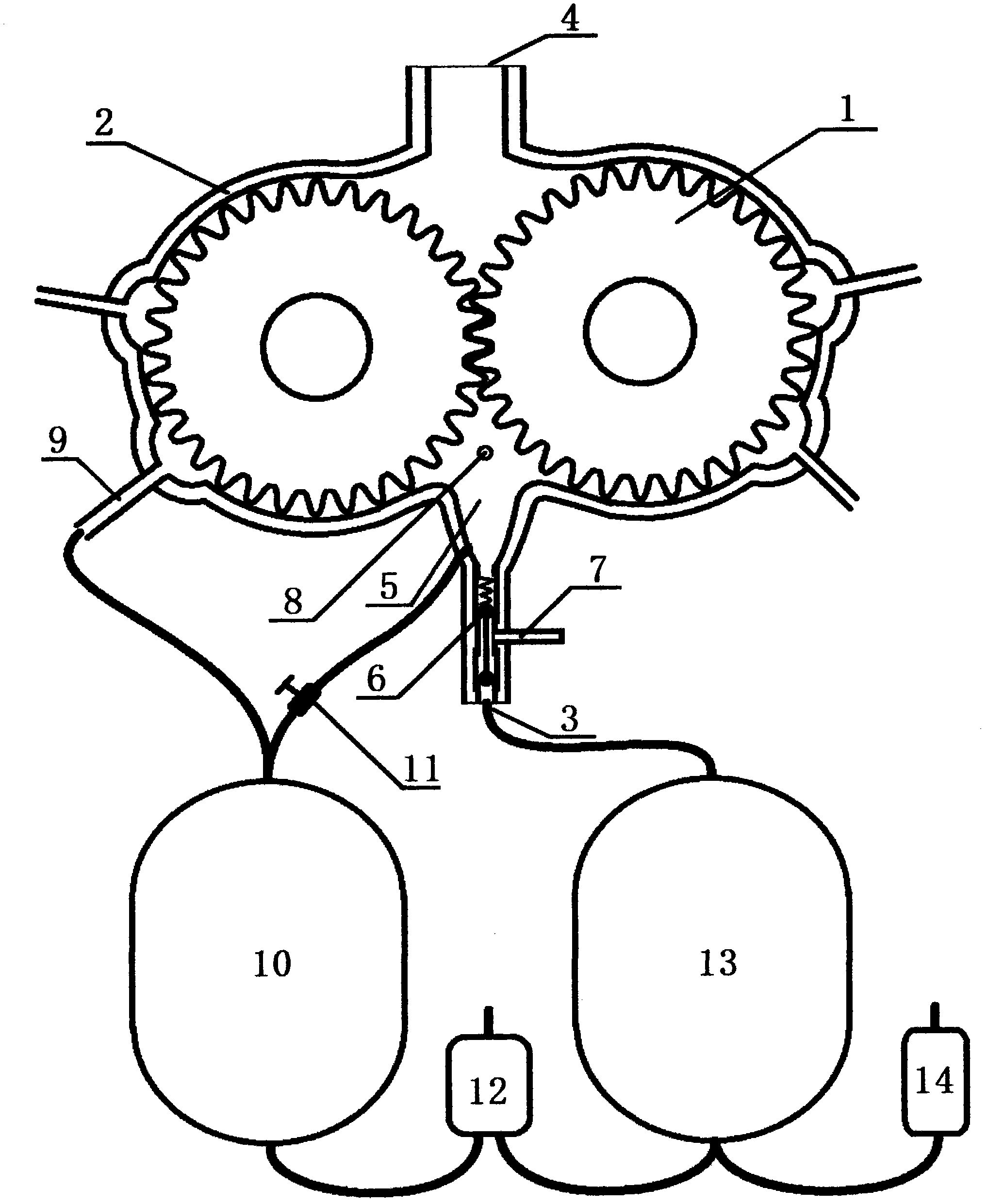

[0032] figure 1 is a schematic diagram of a geared engine.

[0033] 1. The gear motor, including: a double gear 1, a housing 2, an inlet 3, and an outlet 4, which are similar in structure to those in the gear pump, and are characterized in that: on the inner side of the housing 2, the inlet 3 and the two gears 1 are set as The combustion chamber 5 and the inlet 3 are connected to the compressed air tank 13 through the one-way valve 6 , the fuel nozzle 7 is arranged in the inlet 3 , and the ignition device 8 is arranged in the combustion chamber 5 .

[0034] The fuel injection pipe is set in the intake pipe. Although the fuel flows through the compressed air, it enters the combustion chamber through the one-way valve. After ignition, the pressure in the combustion chamber increases, the one-way valve closes, and the gas in the combustion chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com