Meat food safety production chopping and mixing equipment

A safe production and meat-eating technology, which is applied in the fields of mixed meat equipment, processed meat, food science, etc., can solve the problems of shortening the working life, reverse overflow of the feed port, increasing the operation capacity of the chopping shaft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] as attached figure 1 To attach Figure 6 Shown:

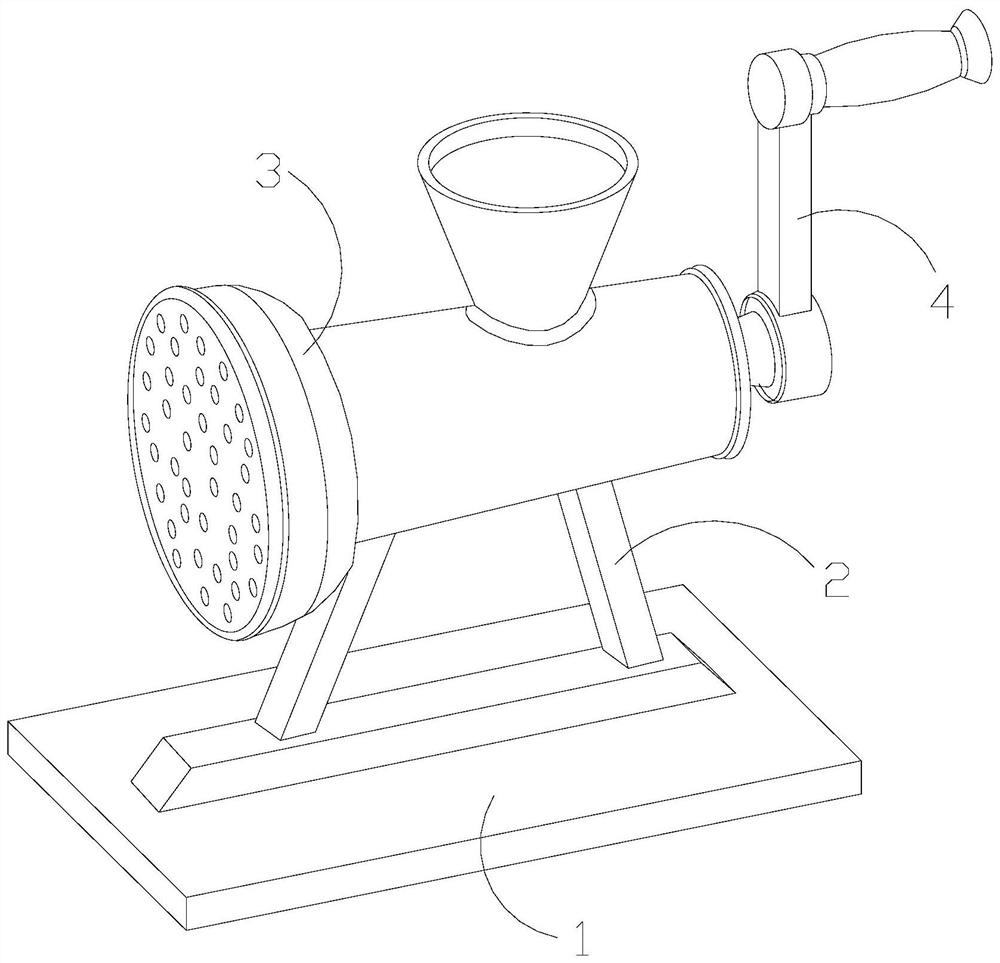

[0032] The invention provides a chopping and mixing equipment for safe production of meat food. Its structure is provided with a base plate 1, a support base 2, an operating device 3, and a hand handle 4. The support base 2 is fixedly installed on the top of the base plate 1, and the operating device 3 Embedded and connected above the support base 2, the handle 4 is connected to the rear end of the operating device 3 and is movably matched.

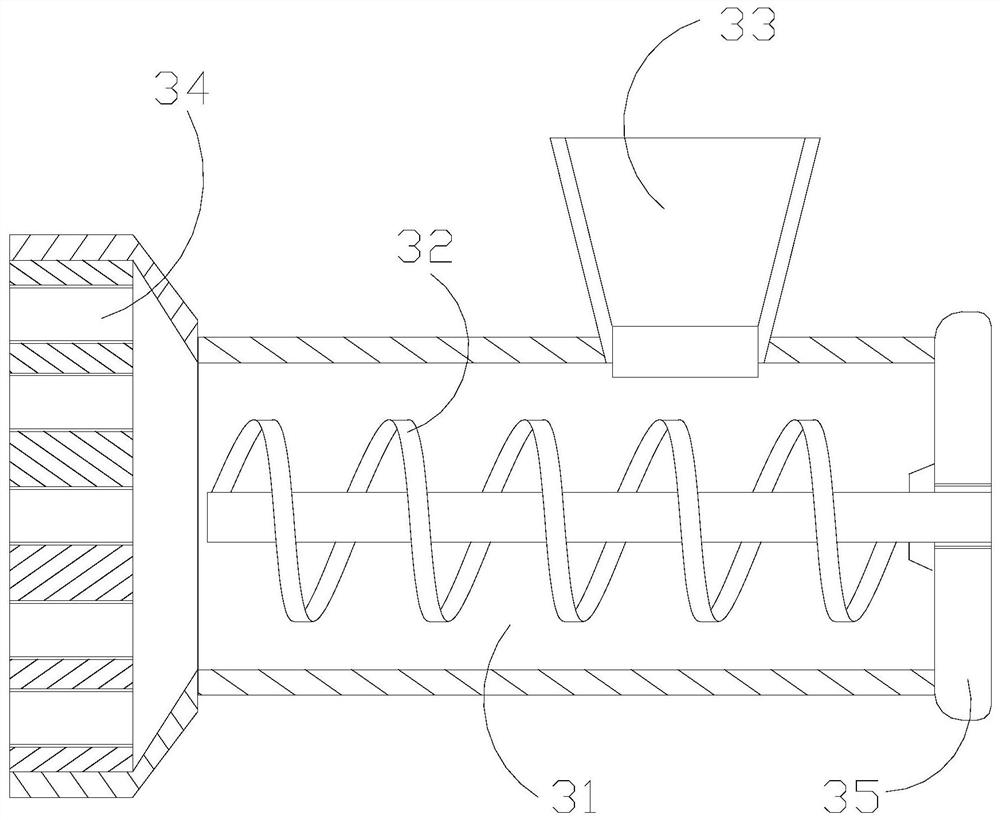

[0033] The operating device 3 is provided with a chopping chamber 31, a chopping shaft 32, a hopper 33, and a discharge port 34. The chopping shaft 32 is embedded and movable inside the chopping chamber 31, and the hopper 33 is fixedly installed in the chopping chamber. The position of the upper end of the mixing chamber 31 is set through and through, the discharge port 34 is located in front of the chopping chamber 31 and connected inside, the chopping shaft 32 is movably matched...

Embodiment 2

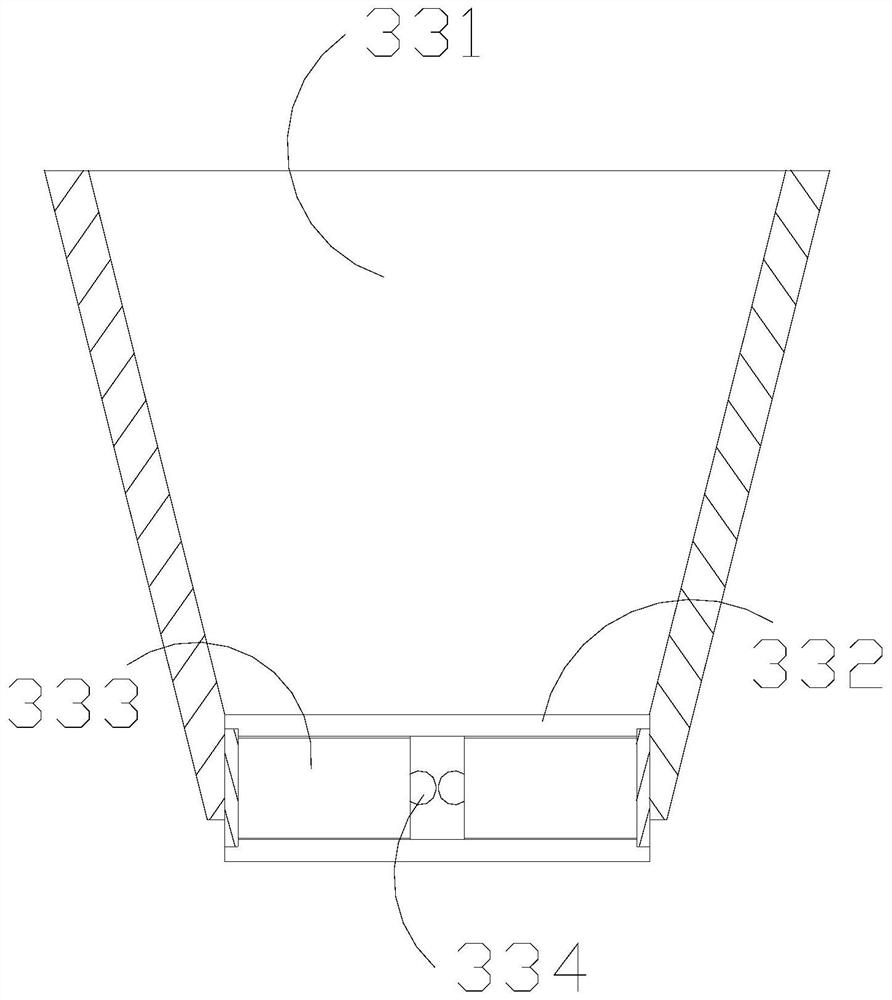

[0040] as attached Figure 7 To attach Figure 9 Shown:

[0041] Wherein, the stop block 334 is provided with a movable block w1 and a card slot w2, the side end of the movable block w1 is hingedly connected to the card slot w2, the movable block w1 is movably engaged in the card slot w2, and the movable The block w1 is spherical and has softness, which can be elastically deformed. The clamping groove w2 is an empty slot with side openings. The movable block w1 swings and engages with the upward and downward pressure received. In the card slot w2, the distance between the two movable blocks w1 that are conveniently set opposite to each other becomes larger, and they are placed at 90 degrees when reset, effectively preventing the meat after being chopped and shredded from overflowing backwards.

[0042] Wherein, the movable block w1 is provided with a hinged block w11, a solid plate w12, and a pressure body w13, and the solid plate w12 is fixedly connected to the side end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com