Cable material with self-repaired functional composite gel and preparation method

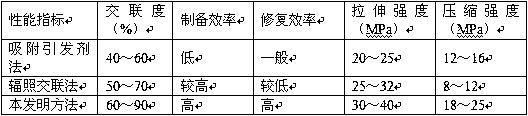

A composite gel and self-healing technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of low crosslinking degree between initiator and gel, harsh reaction conditions, complicated preparation process, etc., to achieve Improved reaction rate and gel cross-linking degree, simple process, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

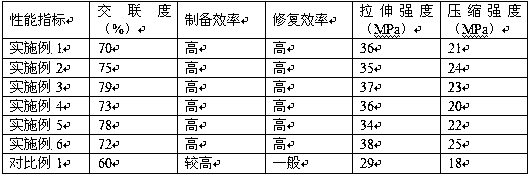

Examples

Embodiment 1

[0034] Potassium persulfate and nano kaolinite clay particles were mixed evenly in a mass ratio of 1:8, and the energy storage solder resist type cold welding machine was used for cold welding at a current of 180A, and the solid initiator was fixed on the surface of the nano clay particles to prepare Obtain composite particle; Then in the reaction vessel, import the nano polyvinyl alcohol powder of 18kg, the ethylene of 72kg, then add the composite particle of 8kg gained, the azone of 2kg and the N of 1kg, N-methylenebisacrylamide, in triggering Under the action of the agent, the monomers are polymerized into macromolecules, and interlinked and intertwined to form a network structure, and the nano-polyvinyl alcohol powder is coated in the gaps of the network structure to obtain a composite gel with self-repairing function; then Take 20kg of composite gel, blend and extrude with 73kg of polyvinyl chloride and 7kg of anti-aging agent to make a cable compound with self-repairing f...

Embodiment 2

[0037]Sodium persulfate and nano-montmorillonite clay particles are mixed evenly in a mass ratio of 1:10, and a high-energy arc welding cold welding machine is used for cold welding at a current of 150A, and the solid initiator is fixed on the surface of the nano-clay particles to obtain Composite particles; then in the reaction vessel, import the nano polyvinyl alcohol powder of 16kg, the propylene of 75kg, then add the composite particles of 6kg gained, the azone of 1kg and the benzoyl peroxide of 2kg, under the effect of initiator, single The body is polymerized into macromolecules, and cross-linked with each other to form a network structure, and the nano-polyvinyl alcohol powder is coated in the gaps of the network structure to obtain a composite gel with self-repairing function; then take 11kg of the composite gel , blended and extruded with 82kg of high-density polyethylene and 7kg of plasticizer to make a cable compound with self-repairing function composite gel;

[00...

Embodiment 3

[0040] Mix ammonium persulfate and nano illite clay particles uniformly in a mass ratio of 1:6, and use a pulse arc welding cold welding machine to cold weld at a current of 200A, and fix the solid initiator on the surface of the nano-clay particles to obtain a composite Particle; Then in the reaction vessel, import the nano polyvinyl alcohol powder of 18kg, the vinyl chloride of 69kg, then add the composite particle of 9kg gained, the azone of 3kg and the 2-ethyl-4 methylimidazole of 2kg, in the initiator Under the action, the monomers are polymerized into macromolecules, and interlinked and intertwined to form a network structure, and the nano-polyvinyl alcohol powder is coated in the gaps of the network structure to obtain a composite gel with self-repairing function; then take 26kg Composite gel with 66kg of low-density polyethylene and 8kg of pigment can be blended and extruded to make a cable compound with self-repairing function of composite gel;

[0041] The cable mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com