New process for preparing hydroxy-acetic acid using hydroxy-acetic nitrile as raw material

A technology of hydroxyacetonitrile and glycolic acid, applied in nitrile preparation, organic chemistry, etc., can solve the problems of complex operation, low efficiency, complicated post-processing, etc., and achieve the effects of easy concentration, effective desalination, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

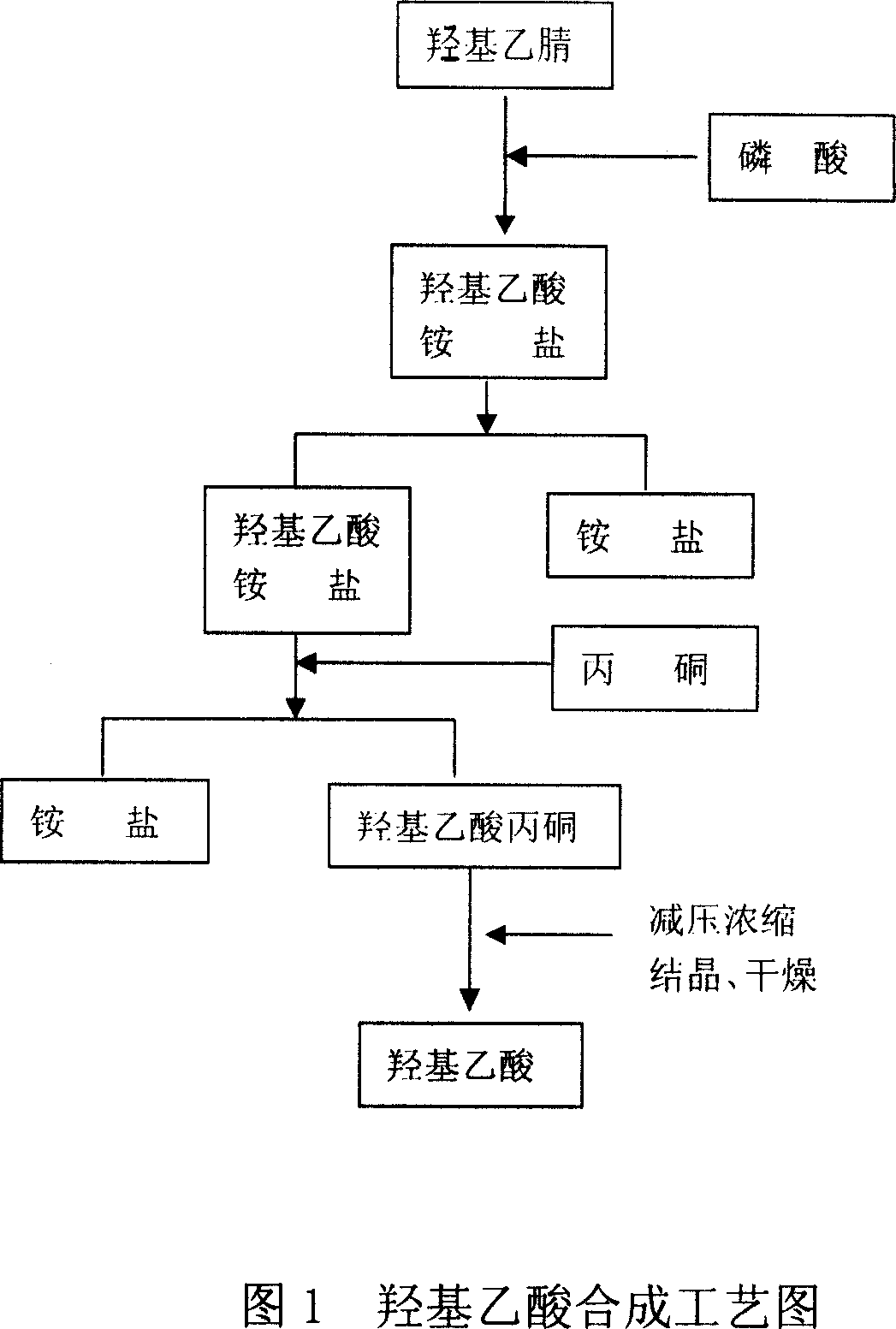

Method used

Image

Examples

Embodiment 1

[0022] Hydroxyacetonitrile 100ml (379g / l), phosphoric acid 84.33g (85%), molar ratio 1: 1.1 in the 500ml four-neck flask at 112 ℃ reflux reaction 17 hours, the conversion rate of hydroxyacetonitrile reaches 99.32%, after concentrated crystallization desalination, The mother liquor was further desalted with 70 ml of acetone, and 27.1 g of glycolic acid with a content of 99.17% was obtained after post-treatment.

Embodiment 2

[0024] Hydroxyacetonitrile 100ml (392.32g / l), phosphoric acid 188.86g (84.5%), molar ratio 1: 2.8 in a 500ml four-neck flask at 90 ° C reflux reaction for 18 hours, the conversion rate of hydroxyacetonitrile reached 99.57%, after concentrated crystallization and desalination , the mother liquor was further desalted with 100ml of acetone, and after post-treatment, 29.3g of glycolic acid was obtained, with a content of 99.23%.

Embodiment 3

[0026] Hydroxyacetonitrile 250ml (410.4g / l), phosphoric acid 435.81g (83.85%), molar ratio 1: 2.1 in a 1000ml four-neck flask at 121 ° C reflux reaction for 16 hours, the conversion rate of hydroxyacetonitrile reached 99.34%, after concentrated crystallization and desalination , the mother liquor was further desalted with 240ml of acetone, and after post-treatment, 62.5g of glycolic acid was obtained, with a content of 98.79%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com