Clean production method for co-producing glycine and iminodiacetic acid

A technology of iminodiacetic acid and monosodium iminodiacetic acid, which is applied in the clean production field of co-production of glycine and iminodiacetic acid, can solve the problems of waste of hydroxyacetonitrile, large amount of decolorizing agent, and low product yield, and achieve The effect of improving yield and purity, high raw material utilization rate, and high product yield

Inactive Publication Date: 2017-05-31

CHONGQING UNISPLENDOUR CHEM

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above-mentioned preparation process has mild reaction conditions, easy control, and simple post-treatment, but it has the following problems: the raw materials are easily decomposed, resulting in the pyrolysis polymerization of aminoacetonitrile and the formation of by-products, and the generation of more colored impurities makes decolorization difficult, and the amount of decolorizer is large. , high energy consumption, low product yield, high energy consumption, high production cost

But there are also problems, mainly including: 1. a large amount of low-value inorganic salt sodium sulfate by-product; 2. produce a large amount of salty, organic waste water; The separation and purification of aminodiacetic acid and sodium sulfate are not thorough, resulting in a low yield of glycine, a large amount of residues in the mother liquor, causing the mother liquor to be unable to circulate; 5. The cost of recycling iminodiacetic acid is too high (the quality of glycine and iminodiacetic acid Ratio is about 10: 1), and qualified iminodiacetic acid cannot be obtained; 6. The utilization rate of hydroxya

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

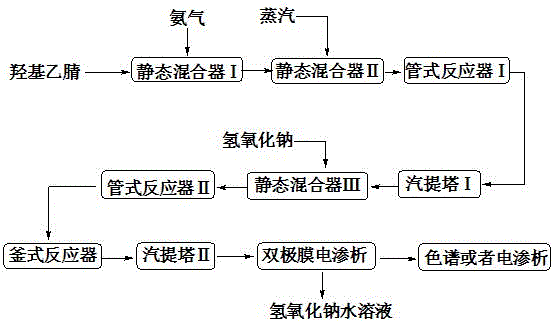

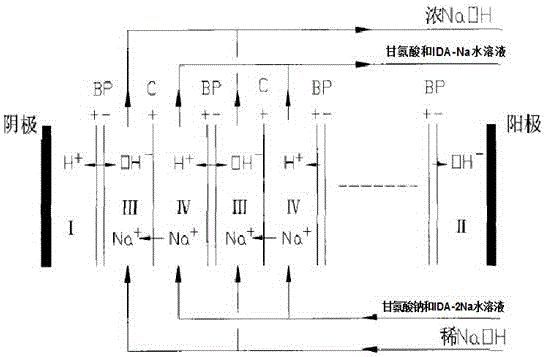

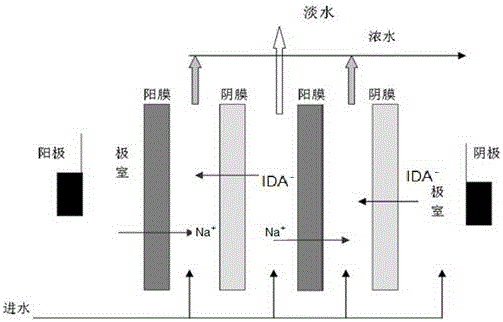

The invention relates to a clean production method for co-producing glycine and iminodiacetic acid. The method comprises the steps: performing ammoniation reaction on hydroxyacetonitrile and ammonia under the condition of high temperature to obtain ammoniation liquid, mixing the ammoniation liquid and alkali, performing pyrohydrolysis, performing deamination and decolorizing treatment, performing bipolar membrane electrodialysis to obtain a glycine-sodium aminodiacetate aqueous solution, performing desalting treatment on the obtained glycine-sodium aminodiacetate aqueous solution to obtain a glycine aqueous solution and a sodium aminodiacetate aqueous solution separately, concentrating, crystallizing and drying the glycine aqueous solution to obtain the glycine, and acidifying, crystallizing and drying the sodium aminodiacetate aqueous solution to obtain the iminodiacetic acid. By the method, coproduction of the glycine and the iminodiacetic acid can be realized, the utilization ratio of the raw materials is high, the effective conversion rate of the hydroxyacetonitrile can reach above 93 percent, other organic byproducts are avoided, the product yield is high, the production cost is low, the byproducts are few, the impurities are few, sodium hydroxide can be recycled, the yield of the glycine and the iminodiacetic acid is greatly increased, and the purity of the glycine and the iminodiacetic acid is greatly improved.

Description

technical field [0001] The invention belongs to the field of chemical industry, and in particular relates to a clean production method for the joint production of glycine and iminodiacetic acid. Background technique [0002] Glycine is an important fine chemical product, which is widely used in medicine, food, chemical industry, pesticide and other fields. The preparation technology of glycine has multiple, and Chinese patent CN1962611B discloses a kind of technology that hydroxyacetonitrile method prepares glycine, comprises the following steps: 1) hydroxyacetonitrile, ammoniacal liquor are mixed, and the mol ratio of reaction material liquid is hydroxyacetonitrile:ammonia=1: 2~10, control the reaction temperature between 20~60°C, and the reaction time is 0.5~8 hours to obtain the ammonia solution of aminoacetonitrile; 2) directly add inorganic alkali to the ammoniated solution obtained in step 1), the reaction mass The molar ratio is aminoacetonitrile: inorganic base=1: 0...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C227/02C07C227/40C07C229/08C07C229/16

CPCC07C227/02C07C227/40C07C253/30C07C229/08C07C229/16C07C255/25

Inventor 吴传隆孙洪飞代小妮韩伟王绪建罗延谷何咏梅韦异勇周明权龙晓钦

Owner CHONGQING UNISPLENDOUR CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com