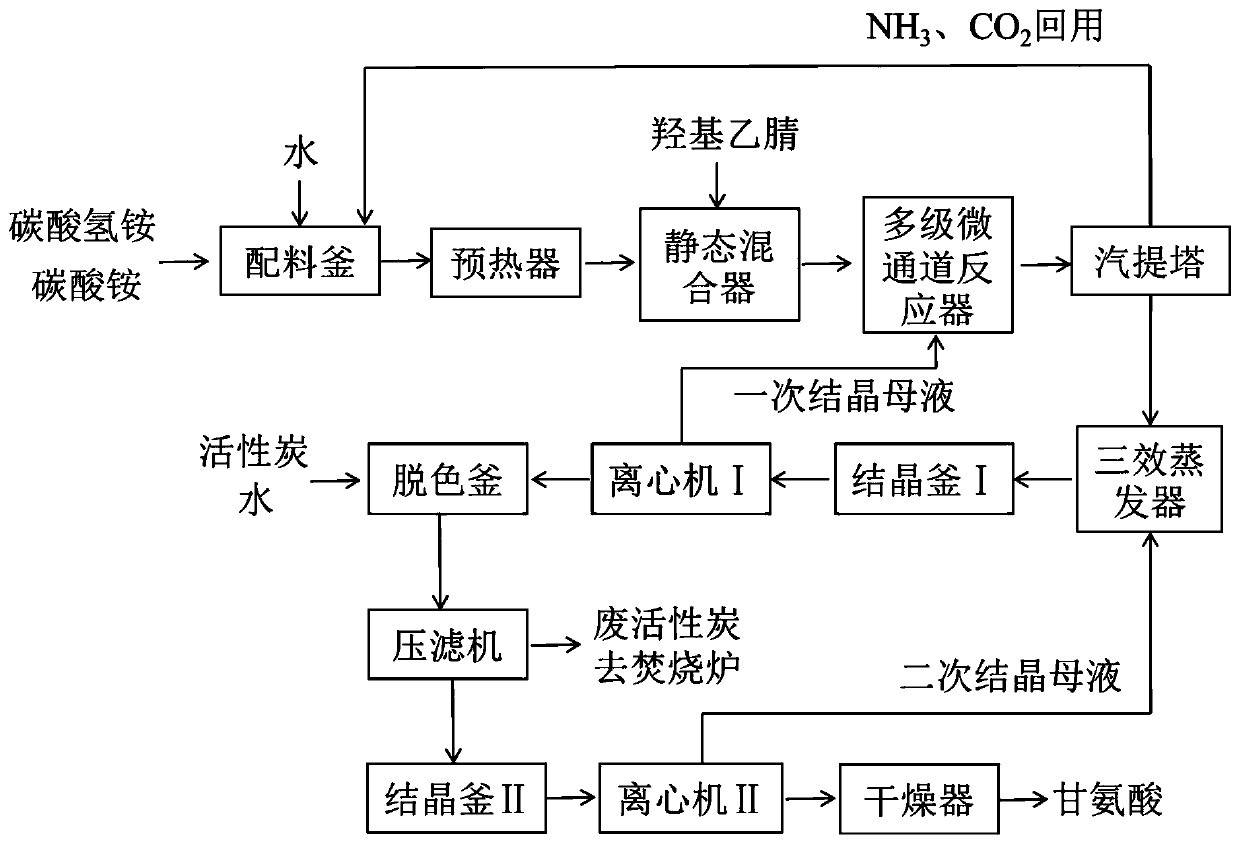

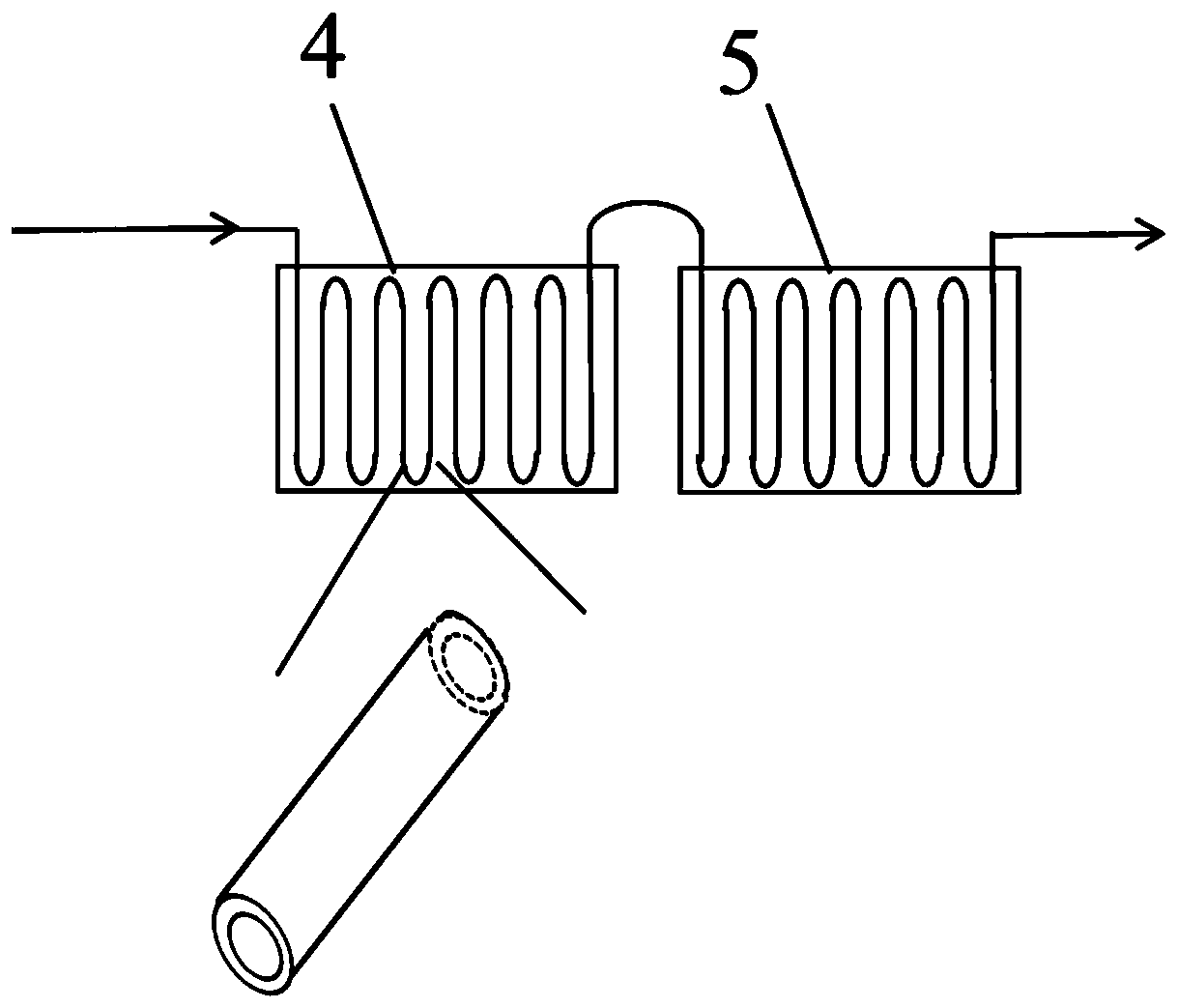

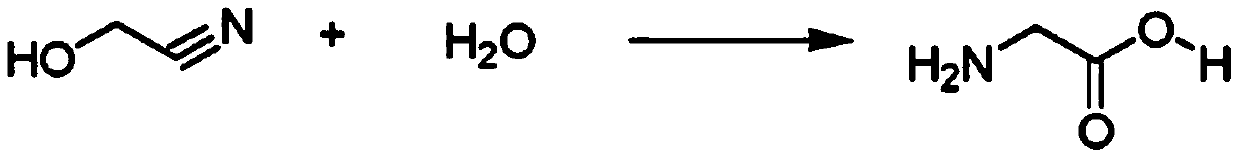

Method for continuously preparing glycine from hydroxyacetonitrile by microchannel reactor

A micro-channel reactor, hydroxyacetonitrile technology, applied in the preparation of cyanide reaction, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of difficult product separation, volatile, and inability to transport long-distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Using hydroxyacetonitrile, ammonium carbonate, ammonium bicarbonate and water as raw materials, mixed according to the molar ratio of 1:3:2:70, transported by the metering pump to the primary microchannel reactor at 50mL / min for synthetic hydantoin reaction, the reaction temperature 80°C, pressure 4MPa, residence time 20min. Subsequently, the synthetic reaction solution was subjected to hydantoin hydrolysis reaction in the second-stage microchannel reactor at a reaction temperature of 120°C, pressure 4MPa, and residence time 40min. The hydrolysis reaction solution is stripped, evaporated and concentrated, crystallized, separated, decolorized, and dried to obtain glycine product with a content of 99.1% and a yield of 97.3%.

Embodiment 2

[0043] Using hydroxyacetonitrile, ammonium carbonate, ammonium bicarbonate and water as raw materials, mixed according to the molar ratio of 1:3:2:70, transported by the metering pump to the primary microchannel reactor at 50mL / min for synthetic hydantoin reaction, the reaction temperature 90°C, pressure 4MPa, residence time 15min, and then, the synthetic reaction liquid was hydrolyzed in the secondary microchannel reactor, the reaction temperature was 135°C, pressure 4MPa, residence time 50min. The hydrolysis reaction solution is stripped, evaporated and concentrated, crystallized, separated, decolorized and dried to obtain a glycine product with a content of 99.3% and a yield of 97.9%.

Embodiment 3

[0045] Using hydroxyacetonitrile, ammonium carbonate, ammonium bicarbonate and water as raw materials, mixed according to the molar ratio of 1:3:2:70, transported by the metering pump to the primary microchannel reactor at 50mL / min for synthetic hydantoin reaction, the reaction temperature 90°C, pressure 4.5MPa, residence time 20min, and then, the synthetic reaction liquid was subjected to hydantoin hydrolysis reaction in the secondary microchannel reactor, reaction temperature 135°C, pressure 4.5MPa, residence time 50min. The hydrolysis reaction solution is stripped, evaporated and concentrated, crystallized, separated, decolorized, and dried to obtain glycine product with a content of 99.5% and a yield of 98.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com