Method for synthesizing monoethanolamine

A synthesis method and ethanolamine technology are applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., can solve problems such as low conversion rate and low yield, and achieve the effect of complete conversion and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

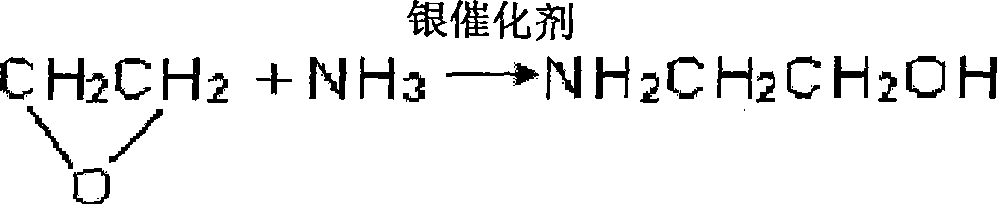

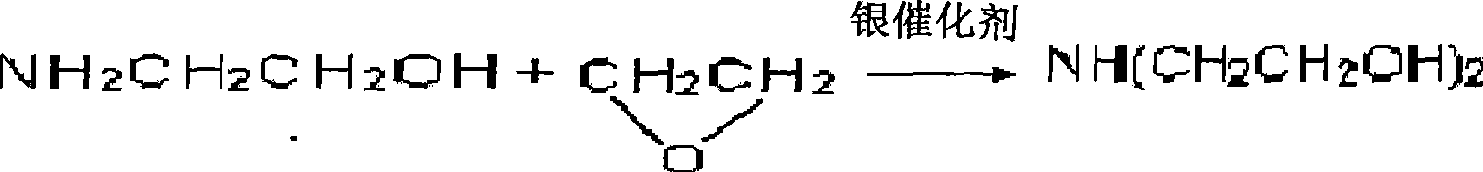

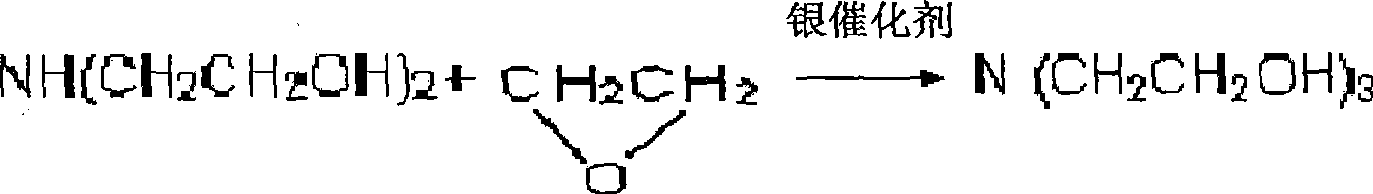

Method used

Image

Examples

Embodiment 1

[0025] The mass percentage concentration is 5% hydroxyacetonitrile aqueous solution 579g and catalyzer is the nickel-aluminum-copper alloy powder 0.144g (the mass percentage of Ni is 98%, the mass percentage of Al is 0.5%, the mass percentage of Cu is the nickel-aluminum-copper alloy powder 0.144g of carrier loading Al and Cu with Ni) The mass percentage is 1.5%) into a 1000mL hydrogenation reactor, under stirring, add 30g of hydrogen from the hydrogenation port of the hydrogenation reactor, control the temperature of the reaction temperature to 200°C, keep the reaction for 18h, and stop when the pressure no longer changes Heating, cooling, discharging, transferring the feed liquid to a 1000mL three-necked flask, and distilling under reduced pressure to obtain 42.8g of pure monoethanolamine. The conversion rate of monoethanolamine is 81.5%, and the yield of monoethanolamine is 70.16%.

Embodiment 2

[0027] The mass percent concentration is 10.2% hydroxyacetonitrile aqueous solution 558.9g and catalyzer is the nickel-aluminum-copper alloy powder 0.057g (the mass percent of Ni is 99%, the mass percent of Al is 0.7%, Cu The mass percentage is 0.3%) into a 1000mL hydrogenation reactor, under stirring, add 22g of hydrogen from the hydrogenation port, control the temperature of the reaction to 80°C, keep the reaction for 16h, stop heating when the pressure no longer changes, and then cool down. Discharging, transferring the feed liquid to a 1000mL neck bottle, and distilling under reduced pressure to obtain 44g of pure monoethanolamine. The conversion rate of monoethanolamine is 81.5%, and the yield of monoethanolamine is 72.13%.

Embodiment 3

[0029] Be that 20.5% hydroxyacetonitrile aqueous solution 278g and catalyzer take Ni as the nickel-aluminum-copper alloy powder 0.085g of carrier loading Al and Cu (the mass percentage of Ni is 97%, the mass percentage of Al is 1.4%, the mass percentage of Cu is The mass percentage is 1.6%) into a 1000mL hydrogenation reactor, under stirring, add 16g of hydrogen gas from the hydrogenation port, control the reaction temperature to 90°C for temperature rise, keep the reaction for 14h, stop heating when the pressure does not change, cool down, and discharge , Transfer the feed liquid to a 1000mL three-necked flask, and distill under reduced pressure to obtain 47g of pure monoethanolamine. The conversion rate of monoethanolamine is 86.5%, and the yield of monoethanolamine is 77.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com