Environmentally-friendly clean technologic production method of highly pure hydantoin

A production method, the technology of hydantoin, applied in the field of high-purity hydantoin in the field of environmentally friendly and clean production, can solve the problems that the product quality is difficult to reach food grade and pharmaceutical grade, the environmental protection problems in the production process are not completely solved, and the production cost remains high. Reduce equipment investment, improve economic and social benefits, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

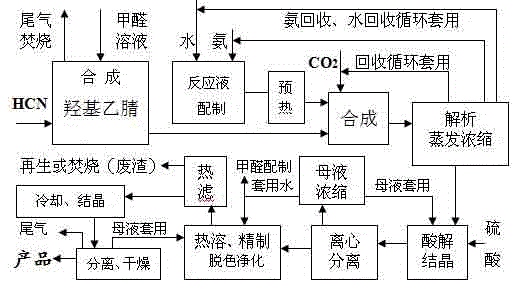

Image

Examples

Embodiment 1

[0045] The purified hydrocyanic acid gas is absorbed by 37% formaldehyde solution to prepare 400g / l hydroxyacetonitrile aqueous solution; ammonia, carbon dioxide, and water are used in a molar ratio of 1:1:15 to prepare an ammonia-containing carbonated water reaction system.

[0046] Add 3500L ammonia-containing carbonated water reaction system to a 5000L pressure reaction kettle. When preheated to 80℃, use a pressure pump to inject 500L of hydroxyacetonitrile aqueous solution at room temperature into the reaction system for reaction, and slowly increase the reaction in 1 hour. The temperature of the system reaches 100°C. When the pressure of the reaction system exceeds 5.0Mpa, slowly release the pressure. After 2 hours of heat preservation and reaction, release the pressure to normal pressure. The carbon dioxide gas released by pressure release contains trace amounts of ammonia and can be directly recovered; The reaction liquid was obtained, and the conversion rate of hydroxyacet...

Embodiment 2

[0048] The purified hydrocyanic acid gas is absorbed by 37% formaldehyde solution, and then a 300g / l hydroxyacetonitrile aqueous solution is prepared; ammonia, carbon dioxide, and water are used in a molar ratio of 1:1:10 to prepare an ammonia-containing carbonated water reaction system.

[0049] Add 3550L ammonia-containing carbonated water reaction system into a 5000L pressure reaction kettle, and when preheated to 80℃, use a pressure pump to inject 450L of hydroxyacetonitrile aqueous solution at room temperature into the reaction system for reaction, and slowly increase the reaction in 1 hour The temperature of the system reaches 100°C. When the pressure of the reaction system exceeds 5.0Mpa, slowly release the pressure. After 2 hours of heat preservation and reaction, release the pressure to normal pressure. The carbon dioxide gas released by pressure release contains trace amounts of ammonia and can be directly recovered; The reaction liquid was obtained, and the conversion r...

Embodiment 3

[0051] The purified hydrocyanic acid gas is absorbed by 37% formaldehyde solution to prepare 400g / l hydroxyacetonitrile aqueous solution; ammonia, carbon dioxide, and water are used in a molar ratio of 1:1:15 to prepare an ammonia-containing carbonated water reaction system.

[0052] Add 3400L ammonia-containing carbonated water reaction system to a 5000L pressure reaction kettle. When preheated to 85℃, use a pressure pump to inject 600L of hydroxyacetonitrile aqueous solution at room temperature into the reaction system for reaction, and slowly increase the reaction in 1 hour. The temperature of the system reaches 100°C. When the pressure of the reaction system exceeds 5.0Mpa, slowly release the pressure. After 2 hours of heat preservation and reaction, release the pressure to normal pressure. The carbon dioxide gas released by pressure release contains trace amounts of ammonia and can be directly recovered; The reaction liquid was obtained, and the conversion rate of hydroxyacet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com