Method and device for clean production of glycine

A clean production, glycine technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of difficult to treat waste water and residues, high energy consumption for separation and purification, difficult separation of mixed liquids, etc., and achieve low production costs. , The effective conversion rate is high, and the effect of increasing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

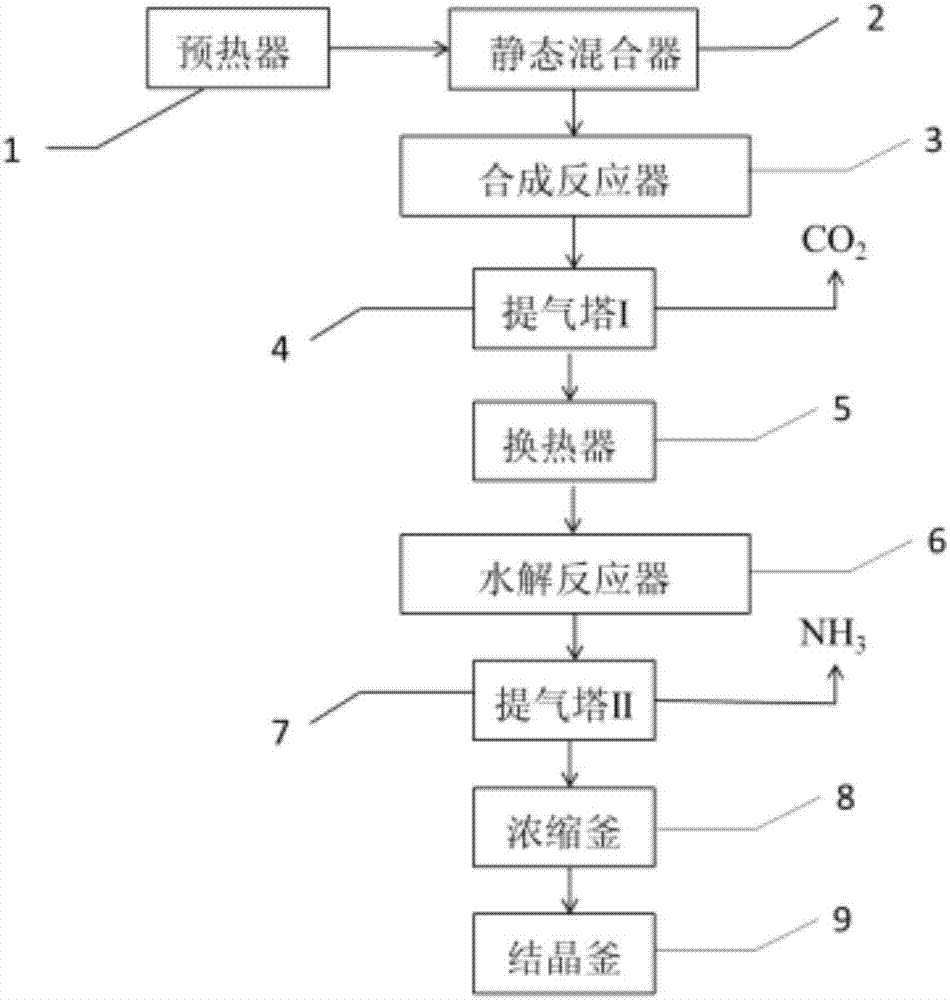

Method used

Image

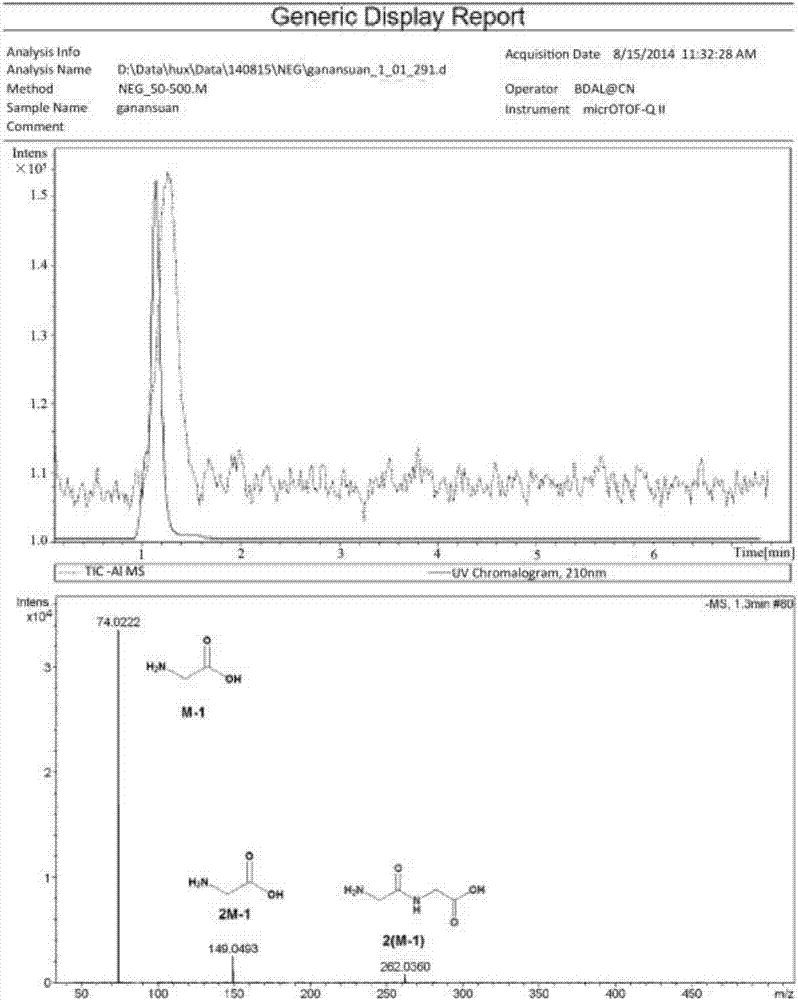

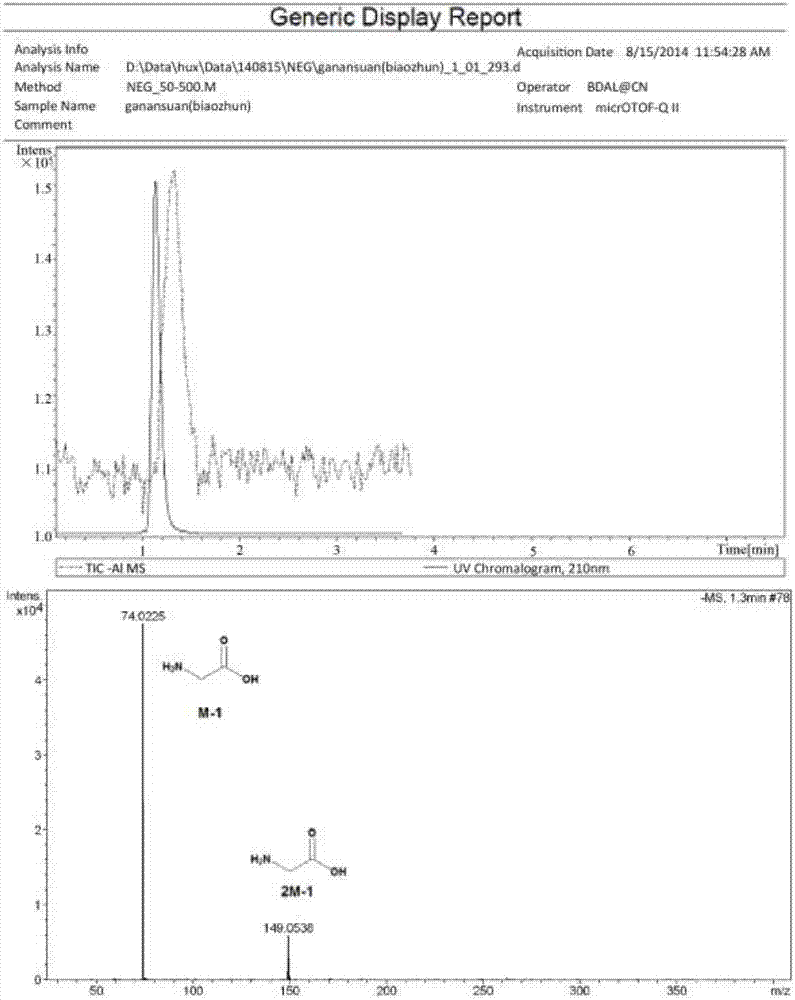

Examples

Embodiment 1

[0063] Adding purity is 99.0% ammonium carbonate 193.94 grams (2.0mol) in the reactor that has pressure sampling device and stirring device 1000ml pressure-resistant lining zirconium material, pure water 483g, be warming up to 60 ℃ (CO 2 / NH 3 = 1:2 molar ratio). When the temperature was raised to 120°C, 95 grams of 40% hydroxyacetonitrile (60°C) was added, and the addition was completed in 1 hour (NH 3 / hydroxyacetonitrile=6:1 molar ratio), the addition rate is 1.21g / min, after the addition is completed, it is kept at 120°C for 1 hour, and the pressure in the reactor is 2.0MPa.

[0064] Release the pressure of the above reaction to normal pressure, then carry out air stripping at 40°C to remove part of the carbon dioxide, and continue to return the obtained feed liquid to the above-mentioned 1000ml reactor to seal it, and immediately raise the temperature to 160°C, and the pressure in the reactor is 2.2MPa , keep warm for 2 hours. After the reaction, release the pressure t...

Embodiment 2

[0067] Add 483 grams of pure water to a 1000ml pressure-resistant zirconium-lined reactor equipped with a pressurized sampling device and a stirring device, preheat to 60°C, add 102 grams of ammonia and 88 grams of carbon dioxide at the same time, and then heat up to 120°C for 30 minutes 95 grams of 40% hydroxyacetonitrile (60° C.) was added through a metering pump, and the molar ratio of hydroxyacetonitrile to ammonia, carbon dioxide, and water was 1:6:3:45. After the addition is complete, keep the temperature at 120° C. for 1 hour, and the pressure in the reactor is 2.1 MPa.

[0068] Release the pressure of the above reaction to normal pressure, then carry out air stripping at 40°C to remove part of the carbon dioxide, and continue to return the obtained feed liquid to the above-mentioned 1000ml reactor to seal it, and immediately raise the temperature to 160°C, and the pressure in the reactor is 2.2MPa , keep warm for 2 hours. After the reaction, release the pressure to no...

Embodiment 3

[0071] Add 483 grams of pure water to a 1000ml pressure-resistant titanium-lined reactor equipped with a pressurized sampling device and a stirring device, preheat to 60°C, add 102 grams of ammonia and 88 grams of carbon dioxide at the same time, then raise the temperature to 120°C, and in 30 minutes 95 grams of 40% hydroxyacetonitrile (60° C.) was added through a metering pump, and the molar ratio of hydroxyacetonitrile to ammonia, carbon dioxide, and water was 1:6:3:45. After the addition is complete, keep the temperature at 120° C. for 1 hour, and the pressure in the reactor is 2.1 MPa.

[0072] Release the pressure of the above reaction to normal pressure, then carry out air stripping at 40°C to remove part of the carbon dioxide, and continue to return the obtained feed liquid to the above-mentioned 1000ml reactor to seal it, and immediately raise the temperature to 160°C, and the pressure in the reactor is 2.2MPa , keep warm for 2 hours. After the reaction, the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com