Method for continuously preparing glycine

A technology of glycine and ammonia source, applied in chemical instruments and methods, preparation of cyanide reaction, preparation of organic compounds, etc., can solve the problems of large volume of reactors, many reactors connected in series, long reaction time, etc., to improve the mass concentration , the effect of reducing the tank reactor and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

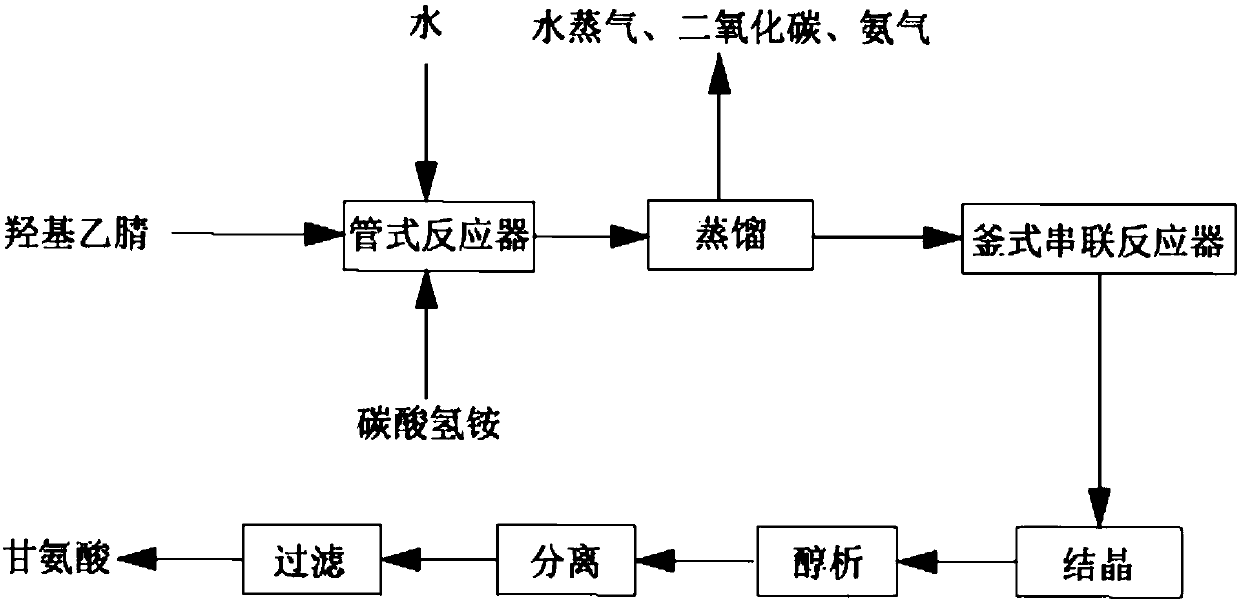

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 glycine

[0048] The raw materials are hydroxyacetonitrile, ammonium bicarbonate and water, and the three substances are mixed according to the molar ratio of 1:2:50, and are transported by the metering pump to the tubular reactor at 350L / hour for the synthesis reaction. The temperature of the tubular reactor is 100°C , pressure 7MPa, reaction time 25min; Hydantoin aqueous solution is concentrated through the rectifying tower, and the concentrated solution mass concentration is 50%; After that, the concentrated solution enters the still-type series reactor (2 kettles in total) for hydrolysis reaction, and the temperature of the reaction kettle 1 150°C, pressure 7MPa, reaction time 0.5 hours, reaction kettle 2 temperature 165°C, pressure 7MPa, reaction time 0.5 hours; the resulting glycine aqueous solution was crystallized twice, ethanol analyzed twice, centrifuged and dried in a spray dryer to obtain refined glycine.

[0049] According t...

Embodiment 2

[0050] The preparation of embodiment 2 glycine

[0051] The raw materials are hydroxyacetonitrile, ammonium bicarbonate and water, and the three substances are mixed according to the molar ratio of 1:2:50, and are transported to the tubular reactor by the metering pump at 350L / hour for the synthesis reaction. The temperature of the tubular reactor is 120 ℃, pressure 7MPa, reaction time 30min; the hydantoin aqueous solution is concentrated by a rectification tower, and the mass concentration of the concentrated solution is 55%. Temperature 150°C, pressure 7MPa, reaction time 0.5 hours, reactor 2 temperature 160°C, pressure 7MPa, reaction time 0.5 hours, reactor 3 temperature 170°C, pressure 7MPa, reaction time 0.5 hours; the resulting glycine aqueous solution was crystallized 2 times, alcohol analysis 2 times, centrifugal separation and spray dryer drying to obtain refined glycine.

[0052] According to the result analysis, the content of glycine is 99.6%, and the yield of gly...

Embodiment 3

[0053] The preparation of embodiment 3 glycine

[0054] The raw materials are hydroxyacetonitrile, ammonium bicarbonate and water, and the three substances are mixed according to the molar ratio of 1:2:50, and are transported to the tubular reactor by the metering pump at 350L / hour for the synthesis reaction. The temperature of the tubular reactor is 120 ℃, pressure 7MPa, reaction time 45min; the hydantoin aqueous solution is concentrated by a rectification tower, and the mass concentration of the concentrated solution is 60%; after that, the concentrated solution enters the reactor series reactor (a total of 3 kettles) for hydrolysis reaction, and the reaction kettle 1 Temperature 150°C, pressure 7MPa, reaction time 0.5 hours, reactor 2 temperature 160°C, pressure 7MPa, reaction time 0.5 hours, reactor 3 temperature 170°C, pressure 7MPa, reaction time 0.5 hours; the resulting glycine aqueous solution was crystallized 2 times, alcohol analysis 2 times, centrifugal separation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com