Method used for continuous preparation of glycine from hydroxyacetonitrile

A technology of hydroxyacetonitrile and glycine, which is applied in chemical instruments and methods, cyanide reaction preparation, organic compound preparation, etc., can solve the problem that glycine cannot realize continuous production, and achieve the continuous production of the whole process, which is environmentally friendly, clean, and material mixing Fully and evenly heated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

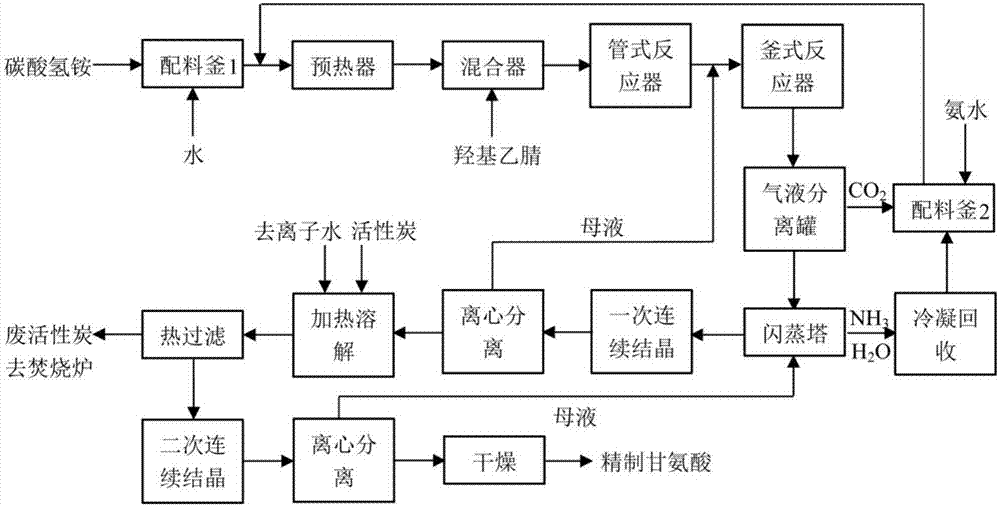

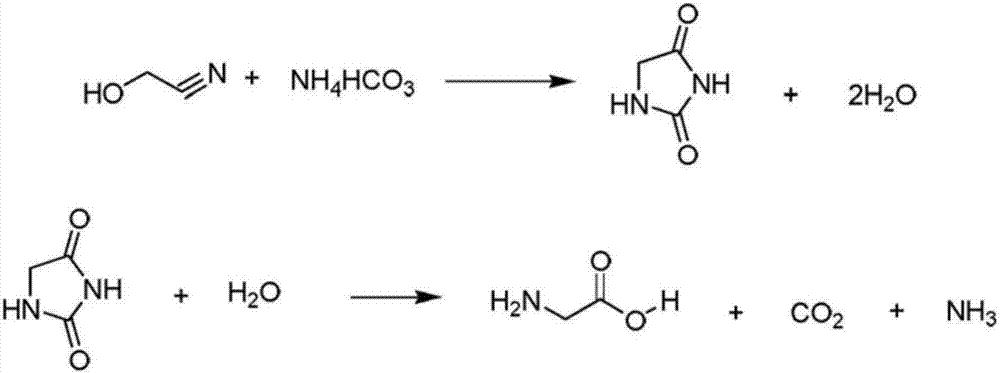

[0035] Embodiment 1: Continuous preparation of glycine with hydroxyacetonitrile

[0036] The raw materials are hydroxyacetonitrile, ammonium bicarbonate and water, and the three substances are mixed according to the molar ratio of 1:2:50, and transported by the metering pump to the tubular packing reactor at 350L / hour for the synthesis of hydantoin and the hydrolysis reaction of hydantoin. The temperature of the first stage of the tubular packing reactor is 90°C, the pressure is 7MPa, and the residence time is 15min; the temperature of the second stage is 130°C, the pressure is 7MPa, and the residence time is 15min; Afterwards, the feed liquid enters the tank-type series reactors to continue the hydantoin hydrolysis reaction. Reactor 1 has a temperature of 160°C, a pressure of 7MPa, and a residence time of 2 hours. Reactor 2 has a temperature of 180°C, a pressure of 7MPa, and a residence time of 1 hour. Reactor 3 The temperature is 200°C, the pressure is 7MPa, and the residenc...

Embodiment 2

[0037] Embodiment 2: Continuous preparation of glycine by hydroxyacetonitrile

[0038] The raw materials are hydroxyacetonitrile, ammonium bicarbonate and water, and the three substances are mixed according to the molar ratio of 1:2:50, and transported by the metering pump to the tubular packing reactor at 350L / hour for the synthesis of hydantoin and the hydrolysis reaction of hydantoin. The temperature of the first stage of the tubular packing reactor is 90°C, the pressure is 5MPa, and the residence time is 15min; the temperature of the second stage is 110°C, the pressure is 5MPa, and the residence time is 15min; 5MPa, residence time 15min. Afterwards, the feed liquid enters the tank-type series reactors to continue the hydantoin hydrolysis reaction. Reactor 1 has a temperature of 150°C, a pressure of 5MPa, and a residence time of 2 hours. Reactor 2 has a temperature of 170°C, a pressure of 5MPa, and a residence time of 1 hour. Reactor 3 The temperature is 190°C, the pressur...

Embodiment 3

[0039] Embodiment 3: Continuous preparation of glycine by hydroxyacetonitrile

[0040] The raw materials are hydroxyacetonitrile, ammonium bicarbonate and water, and the three substances are mixed according to the molar ratio of 1:2:50, and transported by the metering pump to the tubular packing reactor at 350L / hour for the synthesis of hydantoin and the hydrolysis reaction of hydantoin. No modified θ-ring packing was added to the tubular reactor. The temperature of the first stage of the tubular reactor is 90°C, the pressure is 8MPa, and the residence time is 15min; the temperature of the second stage is 130°C, the pressure is 8MPa, and the residence time is 15min; Afterwards, the feed liquid enters the tank-type series reactors to continue the hydantoin hydrolysis reaction. Reactor 1 has a temperature of 160°C, a pressure of 8MPa, and a residence time of 2 hours. Reactor 2 has a temperature of 180°C, a pressure of 8MPa, and a residence time of 1 hour. Reactor 3 The temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com