Preparation and pre-use treatment method for glycolonitrile with cyanide-containing tail gas as raw material

A technology of hydroxyacetonitrile and tail gas, which is applied in the preparation of carboxylic acid nitriles, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of industrial waste water, waste gas, environmental pollution, etc., and achieve the effect of avoiding direct discharge into the atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the screening of catalyst.

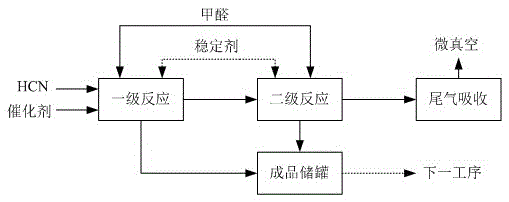

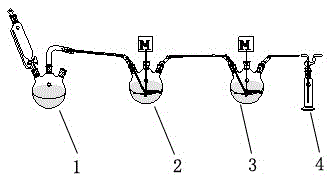

[0017] Basic process such as figure 1 As shown, the reaction device is as figure 2 , Weigh 130g NaCN into the reaction bottle A1, and add 81g of formaldehyde (configured into an aqueous solution with a mass concentration of 37%) into the 500ml reaction bottle B2 and the 500ml reaction bottle C3, and add different catalysts, stir for 10min, and connect Tail gas absorption device 4, use the dropping funnel to slowly add acetic acid to the reaction bottle A1, control the dropping speed and control the temperature of the reaction bottle B2 to 15°C with a water bath, and take a sample to detect the product concentration in the reaction bottle B2 after 1 hour of reaction. Experimental results show that various bases can play a catalytic role, sodium sulfite is relatively ideal, but the amount of catalyst directly affects the pH of the reaction system, so the input amount of reaction catalyst base must be strictly controlled. If th...

Embodiment 2

[0020] Example 2: Screening of catalyst addition.

[0021] Basic process such as figure 1 As shown, the reaction device is as figure 2 , Weigh 130g NaCN into reaction bottle A1, and add 81g formaldehyde (configured into an aqueous solution with a mass concentration of 37%) into 500ml reaction bottle B2 and 500ml reaction bottle C3, and add different amounts of catalyst NaCN 2 SO 3 , stirred for 10 minutes, connected the tail gas absorbing device 4, slowly added acetic acid dropwise to the reaction bottle A1 with a dropping funnel, controlled the dropping speed and controlled the temperature of the reaction bottle B2 to 15°C with a water bath, and took samples at intervals to detect the remaining formaldehyde in the reaction bottle B2 When the concentration of formaldehyde in the reaction solution is ≤0.5%, the reaction is considered to be over. After the end, sulfuric acid is used as a stabilizer to adjust the pH to 2.0, and the reaction end time is recorded. The concentra...

Embodiment 3

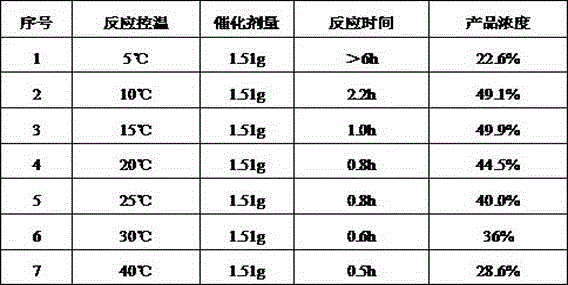

[0024] Embodiment 3: determination of reaction temperature.

[0025] Basic process such as figure 1 As shown, the reaction device is as figure 2 As shown, in combination with the above experiments, 130g of NaCN was weighed into the reaction bottle A1, and 81g of formaldehyde (configured into an aqueous solution with a mass concentration of 37%) was added to the 500ml reaction bottle B2 and 500ml reaction bottle C3, and NaCN was added. 2 SO 3 , stirred for 10 minutes, connected the tail gas absorption device 4, slowly added acetic acid dropwise to the reaction bottle A1 with a dropping funnel, added dropwise at a certain speed and controlled different reaction temperatures with a water bath, and took samples at intervals to detect the remaining amount of formaldehyde in the reaction bottle B2 , when the concentration of formaldehyde in the reaction solution is ≤0.5%, the reaction is considered to be over, and after the end, sulfuric acid is used as a stabilizer to adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com