Culture of bacillus alcaligenes and method for preparing glycolic acid by using the same to hydrolyzing nitrile

A technology for catalyzing hydroxyacetonitrile and glycolic acid with nitrilase, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, hydrolytic enzymes, etc., and can solve problems such as poor tolerance of hydroxyacetonitrile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 microbial shake flask culture

[0053] Inoculate 50mL seed medium (10g of glycerol, 5g of peptone, 5g of yeast extract, KH 2 PO 4 2g, NaCl 1g, MgSO 4 0.2g, water 1000mL, pH 8.0) in the pre-cultivation for 15h, with the culture solution as the seed solution, inoculated to 200mL fermentation medium (ammonium acetate 15g, peptone 10g, yeast extract 6g, KH 2 PO 4 2g, NaCl2g, MgSO 4 0.4g, Auxin FeSO 4 ·7H 2 O 0.5g, inducer phenylacetonitrile 0.2g, water 1000mL, pH 8.0), cultured on a shaker at 160rpm at 30°C for 48h.

Embodiment 2

[0054] Embodiment 2 nitrilase bacterial strain activity comparison

[0055] The isolated Alcaligenes sp.ECU0401 was compared with the nitrilase activity of Rhodococcus erythropolis1.2362, Rhodococcus rhodochrous ECU1201 and Rhodococcus ruber 4.1187. Suspend the resting cells of the above-mentioned four strains in 100mL potassium phosphate buffer solution, add hydroxyacetonitrile at a final concentration of 20mM, shake and react at 30°C and 160rpm for 30min, and immediately add to the supernatant 2 MH 2 SO 4 Acidify to a pH of 1.0-2.0 to terminate the reaction, centrifuge the reaction solution at 10,000×g for 15 minutes, remove cells, and analyze by HPLC. It is found that Alcaligenes sp.ECU0401 has a higher activity in nitrile hydrolysis of p-hydroxyacetonitrile. The reaction solution was analyzed by ion chromatography, and no possible by-products of glyoxylic acid, formic acid and oxalic acid were found, and the product glycolic acid was not metabolized.

[0056] Table 1 Ni...

Embodiment 3

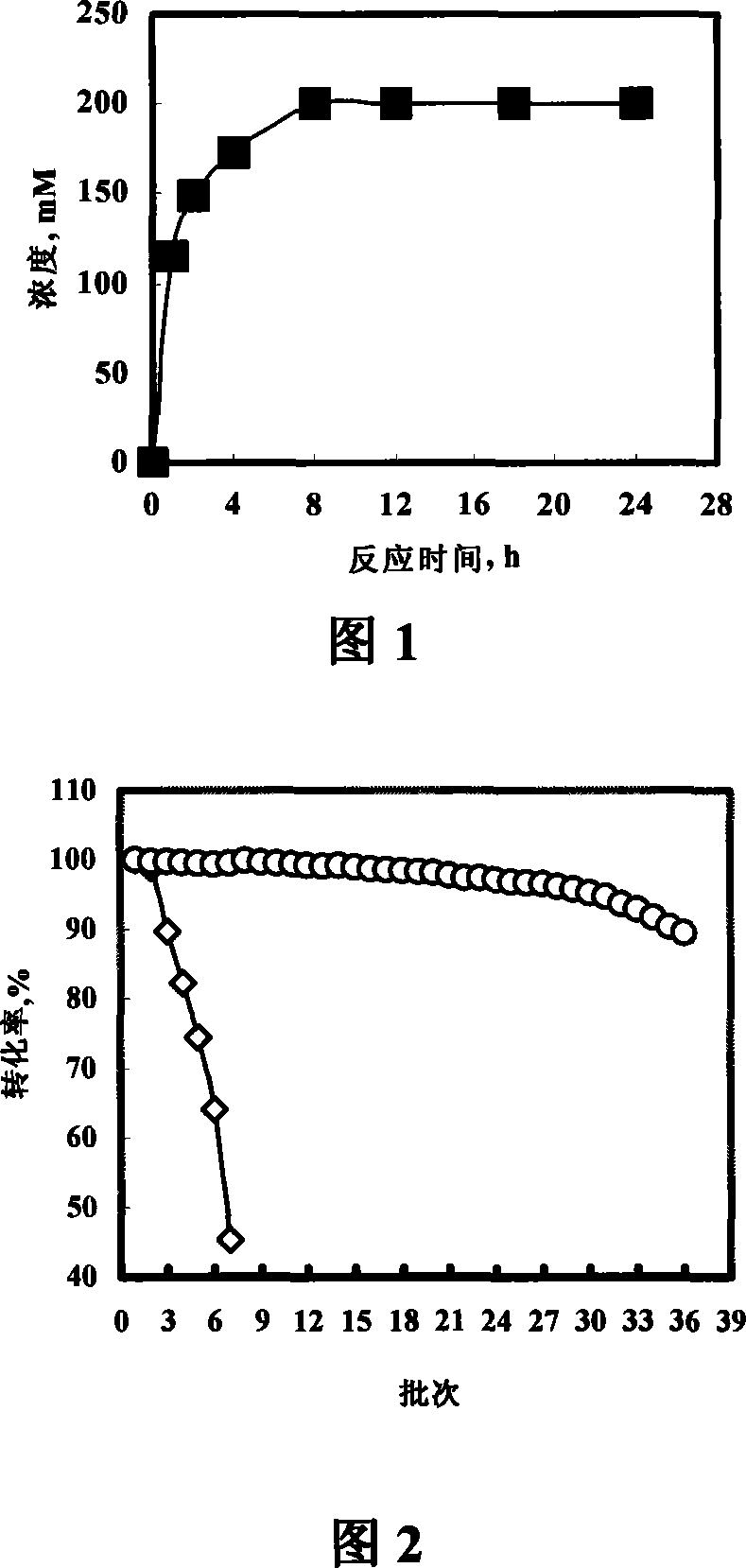

[0058] Example 3 Utilize Alcaligenes sp.ECU0401 to grow cells

[0059] Catalytic hydrolysis of hydroxyacetonitrile to produce glycolic acid

[0060] Prepare seed medium (glycerol 10g, peptone 5g, yeast extract 5g, KH 2 PO 4 2g, NaCl 1g, MgSO 4 0.2g, water 1000mL, pH 8.0), put 200mL seed medium into a 1L shake flask, and cultivate the seed liquid. Then prepare the fermentation medium (ammonium acetate 15g, peptone 10g, yeast extract 6g, KH 2 PO 4 2g, NaCl 2g, MgSO 4 0.4g, Auxin FeSO 4 ·7H 2 (00.5g, inducer benzyl nitrile 0.2g, water 1000mL, pH 8.0). Put 3L fermentation medium in a 5L fermenter, insert 5% seed liquid after disinfection, carry out fermentation and cultivation for 24 hours, add 100mM hydroxyacetonitrile, take samples for HPLC analysis at different times, and continue to supplement when the yield of glycolic acid analysis is 96%. Add 100mM of hydroxyacetonitrile solution neutralized by sodium hydroxide and 10g of ammonium acetate. When the cumulative c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com