Novel glycine synthesis process

A technology of glycine and new process, applied in the field of new process of glycine synthesis, can solve the problems of low quality of ammonium chloride, large energy consumption by-products, increase production cost, etc., and achieve the reduction of dosage, energy consumption and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

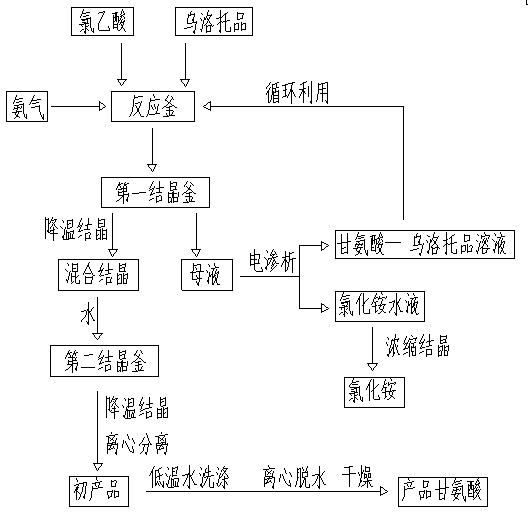

[0030] A new process for synthesizing glycine, comprising the following process steps:

[0031] A, prepare the chloroacetic acid solution in the reactor, and add urotropine, slowly feed ammonia into the reactor for reaction, when the pH of the solution is 8, the ammonia is finished;

[0032] B. After the reaction is completed, the solution is transferred to the first crystallization kettle for the first cooling crystallization, and then the mixed crystallization of glycine and ammonium ammonia is obtained by centrifugation, and the remaining mother liquor is used for subsequent use;

[0033] C. Put the mixed crystals into the second crystallization tank and add water to dissolve them, then carry out the second cooling crystallization, and obtain the initial product by centrifugal separation, wash the initial product with low-temperature water, perform centrifugal dehydration after washing, and finally dry to obtain Glycine products;

[0034] D. The mother liquor is separated ...

Embodiment 2

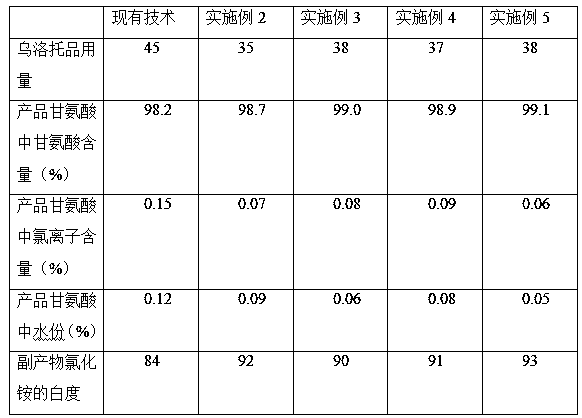

[0036] On the basis of embodiment 1, preferred:

[0037] In step A, the concentration of the chloroacetic acid is 80%.

[0038] In step A, the quality of urotropine after the addition of urotropine is 20% of the quality of chloroacetic acid.

[0039] In step A, the controlled rate of adding ammonia gas keeps the temperature in the reactor at 65°C.

[0040] In step B, the crystallization temperature at lower temperature is 6°C.

[0041] In step C, the crystallization temperature at lower temperature is 6°C.

[0042] In step C, the temperature of the low temperature water is 5°C.

[0043] In step C, the washing is performed until the chloride ion concentration is less than 0.5%.

[0044] In step C, the drying temperature is 120°C.

Embodiment 3

[0046] On the basis of embodiment 1, preferred:

[0047] In step A, the concentration of the chloroacetic acid is 80%.

[0048] In step A, the quality of urotropine after the addition of urotropine is 28% of the quality of chloroacetic acid.

[0049] In step A, the controlled rate of adding ammonia gas keeps the temperature in the reactor at 95°C.

[0050] In step B, the temperature of the cooling crystallization is 25°C.

[0051] In step C, the temperature of the cooling crystallization is 25°C.

[0052] In step C, the temperature of the low temperature water is 10°C.

[0053] In step C, the washing is performed until the chloride ion concentration is less than 0.5%.

[0054] In step C, the drying temperature is 155°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com