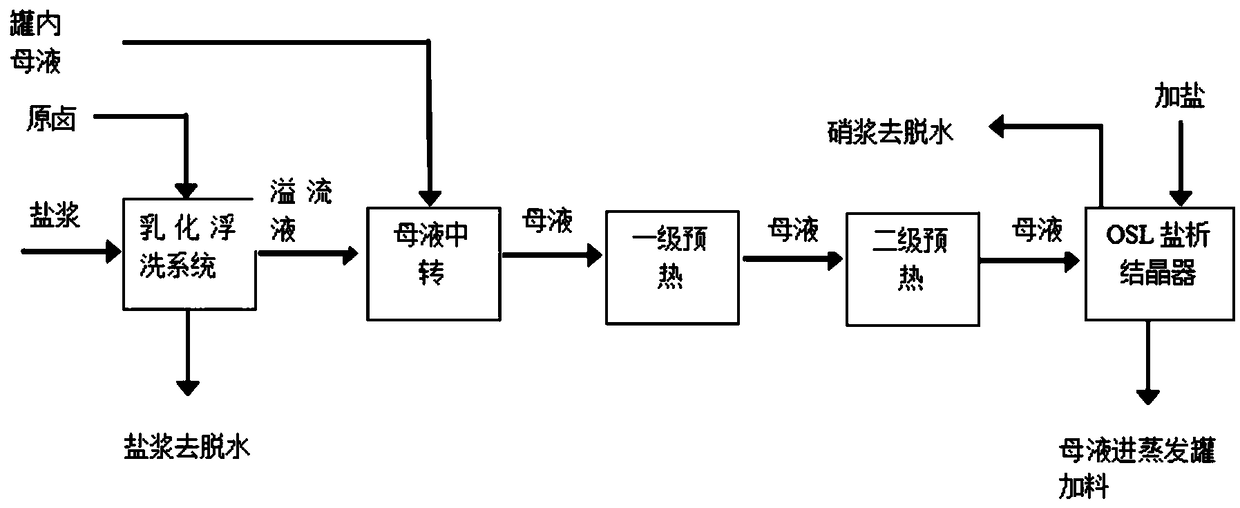

Production process for extracting mirabilite by continuous salting-out hot process

A production process and thermal method technology, applied in the field of co-production of salt and nitrate, can solve problems affecting product quality, heat, material imbalance, complex process route, etc., to avoid primary nucleation, continuous and controllable production, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

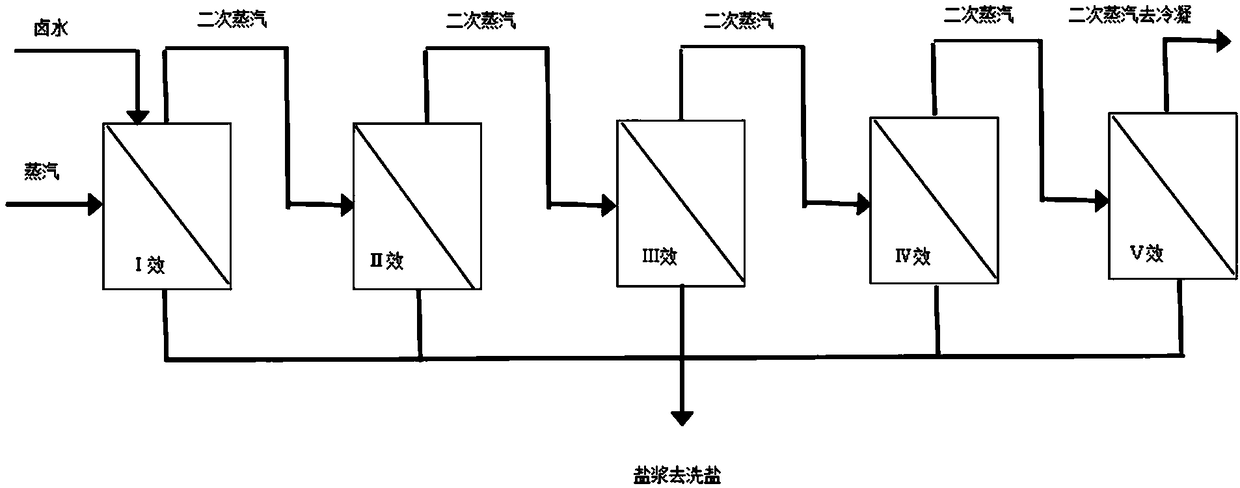

Method used

Image

Examples

Embodiment 1

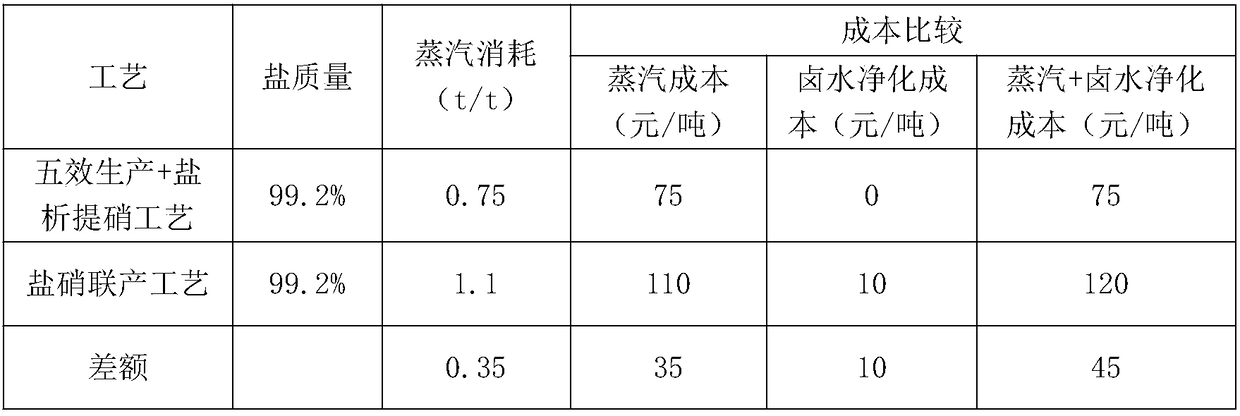

[0033]The present invention aims at the present situation that the production technology and equipment of the salt-nitrate co-production process generally adopted by domestic sodium sulfate-type brine salt production enterprises are outdated and the manufacturing cost is high, and a set of using the reverse solubility of sodium sulfate and the principle of the same-ion effect of sodium ions is developed. A small amount of mother liquor is discharged from the tank, and the salt slurry is discharged into the vertical salt washer for three-stage countercurrent emulsification and floating washing. The mass ratio of the amount of brine to the salt slurry is adjusted to 1:1, and the temperature of the mother liquor after washing is controlled to be ≤35°C to achieve the best. Washing effect, the quality of the washed salt slurry is qualified, all of which reach the national standard high-grade products (sodium chloride content ≥ 99.1%). The washed salt slurry is directly centrifugal de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com