Patents

Literature

118results about How to "To achieve the purpose of comprehensive utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for purifying sesamin and sesamolin

InactiveCN101602768AHigh purityEasy to operateOrganic chemistryMetabolism disorderFiltrationSesamolin

The invention relates to a method for purifying sesamin and sesamolin in sesame oil, which comprises the steps of: separating lignanoid compounds without fat constituents from the sesame oil first; adding ether into the lignanoid compounds to precipitate the sesamin; performing the filtration; dissolving an obtained filtrate by chloroform after concentration under reduced pressure, adding petroleum ether into the mixture until white opacity appears; heating and dissolving the obtained solution; and standing the obtained solution to precipitate the sesamolin. The method for purifying the sesamin and the sesamolin has the advantages of simple operation, safety, economization, strong process stability and the like, and is particularly suitable for industrialized application; and the method can synchronously obtain high-purity sesamin and sesamolin, and achieve the aim of comprehensive utilization.

Owner:河南省农科院农副产品加工研究所

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

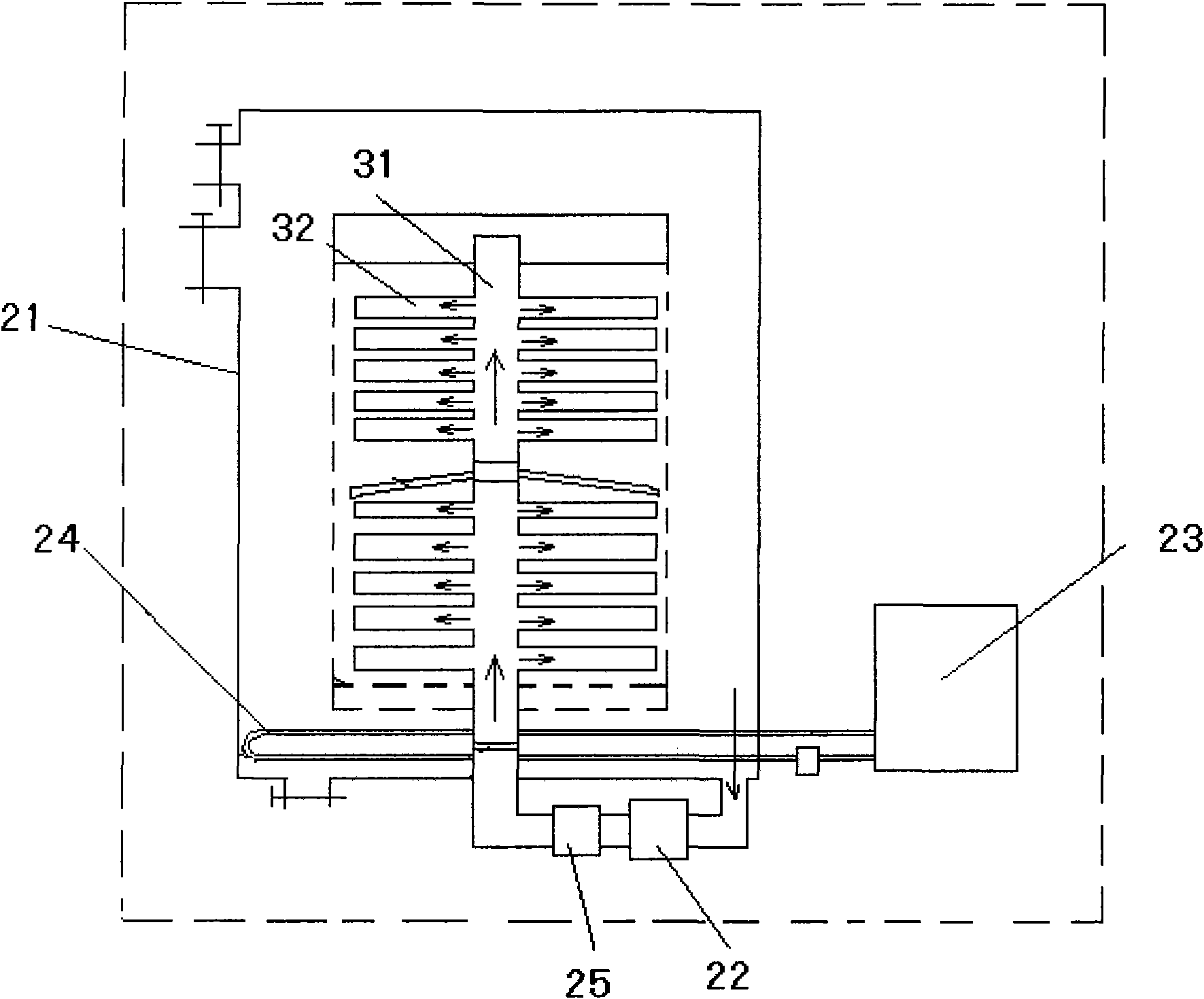

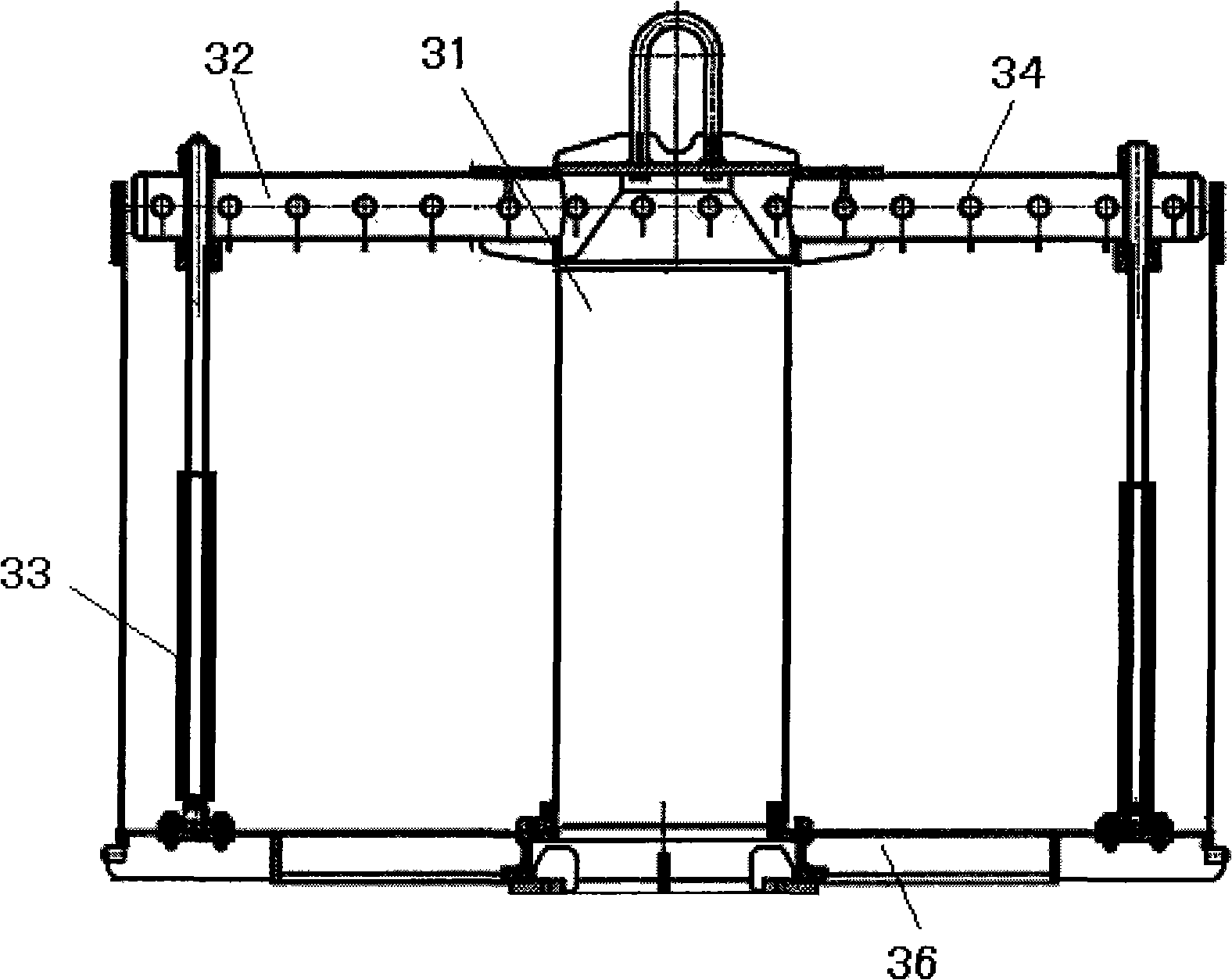

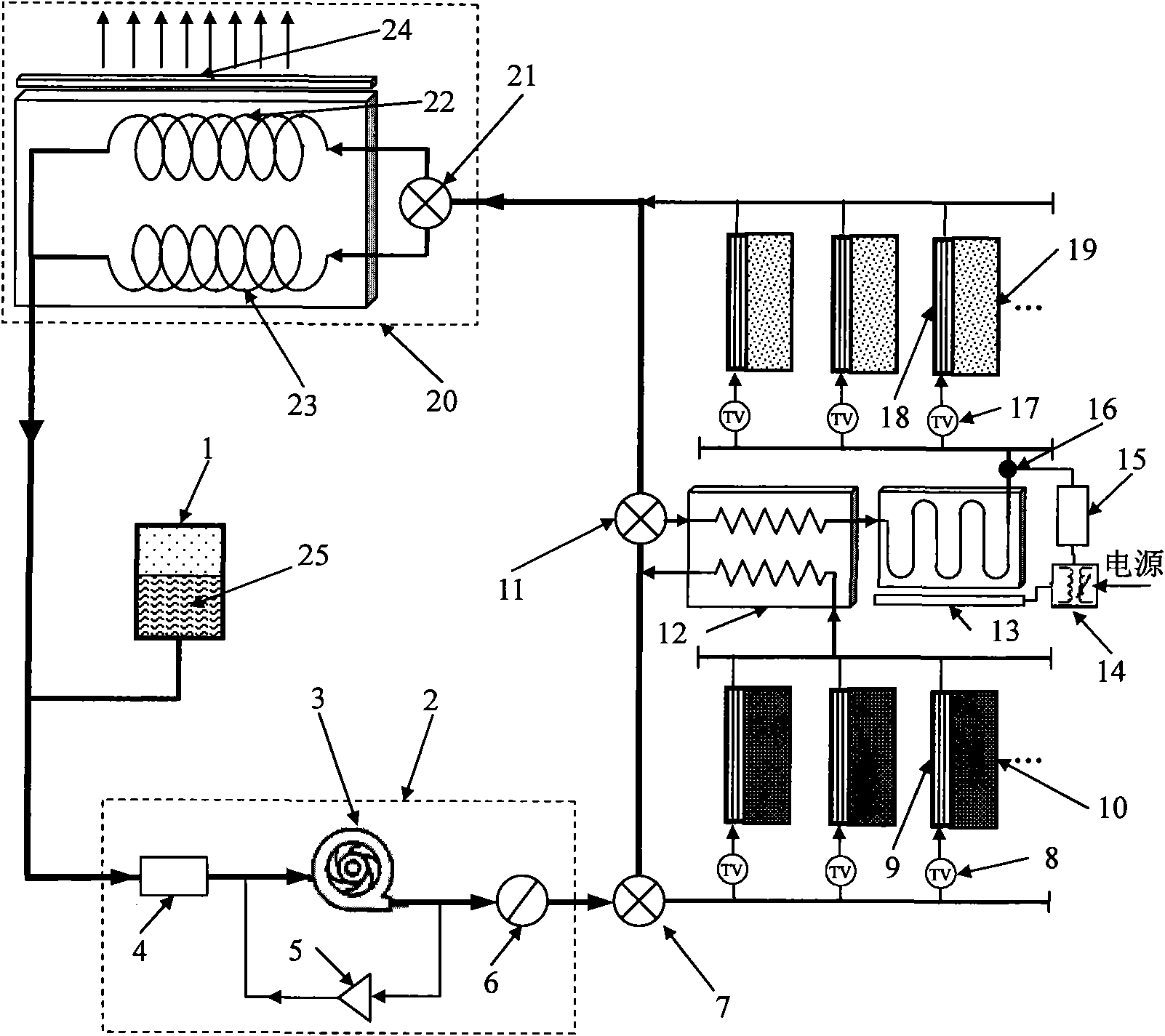

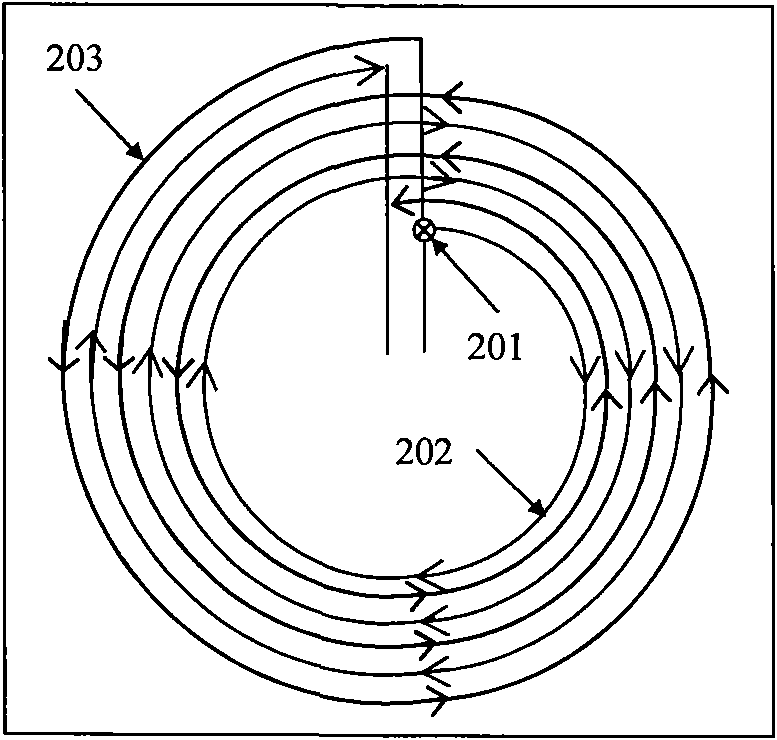

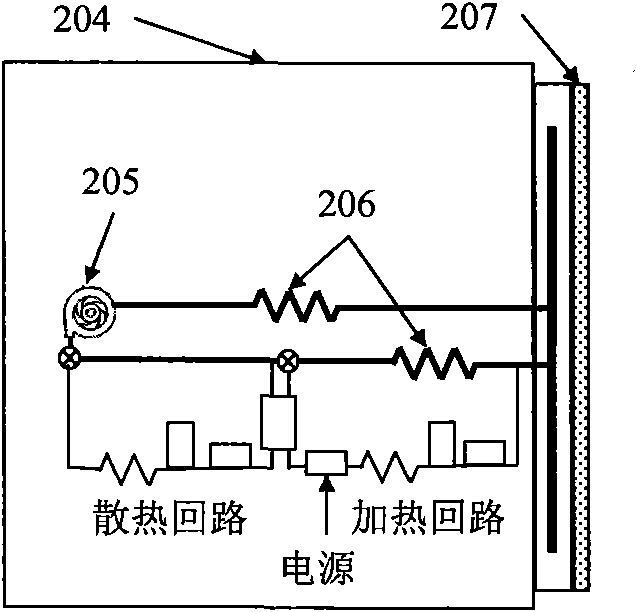

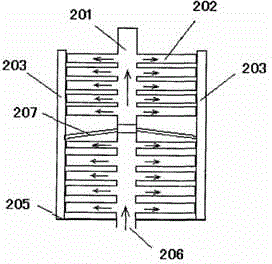

Actuating mechanism of spacecraft for integrating heat control and liquid momentum wheel

InactiveCN101633411AEasy to integrateIncrease functional densityCosmonautic environmental control arrangementMomentumAngular momentum

The invention relates to an actuating mechanism of a spacecraft for integrating the heat control and a liquid momentum wheel, comprising a liquid storage device, a circulating pump assembly, a heat-dissipating public loop, a heating assembly, a heating public loop and an irradiator / momentum generator integration device, wherein the circulating pump assembly is used for driving liquid working substance to flow; the heat-dissipating public loop includes a first flow rate distribution valve, a first heat exchanging device and a first bypassing branch, wherein the first heat exchanging device is connected in parallel with the first bypassing branch; the heating assembly heats fluid working substance for heating the heat-dissipating public loop; the heating public loop includes a second flow rate distribution valve, a second heat exchanging device and a second bypassing branch, wherein the second heat exchanging device is connected in parallel with the second bypassing branch; the irradiator / momentum generator integration device comprises at least two different pipelines which are connected in parallel and a device which controls the distribution of the liquid momentum in the different pipelines, and are used for dispersing heat out of the spacecraft and providing large enough and changeable angular momentum; the heat-dissipating public loop, the heating public loop and the irradiator / momentum generator integration device are sequentially connected and then in series connected with the liquid storage device and the circulating pump assembly to form a working substance circulating loop, and the liquid working substance flows in the working medium circulating loop.

Owner:HARBIN INST OF TECH

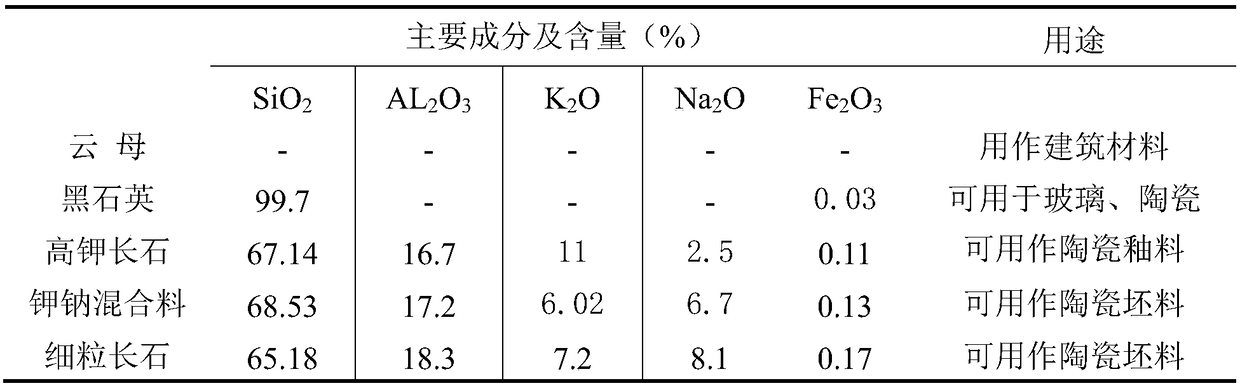

Iron-removing concentrating process of potash feldspar

InactiveCN101028610ARich varietyNo flappy problemsSievingScreeningResource utilizationDiiron Trioxide

An iron-removing ore dressing technology for potash feldspar includes such steps as washing, breaking, sorting, concentrating, purifying, washing with sulfuric acid and sieving. It has high output (more than 90%), low content of Fe (less than 0.24%) and more by-products (silt, Fe, mica, Fe2O3 and Fe3O4).

Owner:王连民

Stainless steel slag dry magnetic separation device and process

PendingCN109365106ARealize more breaking and less grinding”Realize dry grindingGrain treatmentsMagnetic separatorSlag

The invention discloses a stainless steel slag dry magnetic separation device and process, and belongs to the technical field of metallurgy and mineral engineering. The device comprises a raw materialbin, a scrap steel collecting device, a crushing and screening device and a magnetic separator; the magnetic separator comprises a magnetic separation unit, a screening. mechanism and an abrasive mechanism; and the crushing and screening device comprises a crushing mechanism, a separating mechanism and a dispersing mechanism. The process comprises the steps of primary crushing and screening, secondary crushing, screening and iron removal, material dispersing, primary magnetic separation screening and secondary magnetic separation. In the treatment process of stainless steel slag, 58-60% of stainless steel slag does not need to be ground, the purposes of more crushing and less grinding of steel slag, dry grinding and tailings dry discharge are achieved, the content of free calcium oxide ina desulfurization agent is increased, and the desulfurization efficiency of the desulfurization agent is improved; and water is not consumed during treatment, a tailings pond does not need to be arranged, the production process is shortened, and the metal recovery rate in the process of selecting iron from stainless steel slag is increased.

Owner:JIUQUAN IRON & STEEL GRP

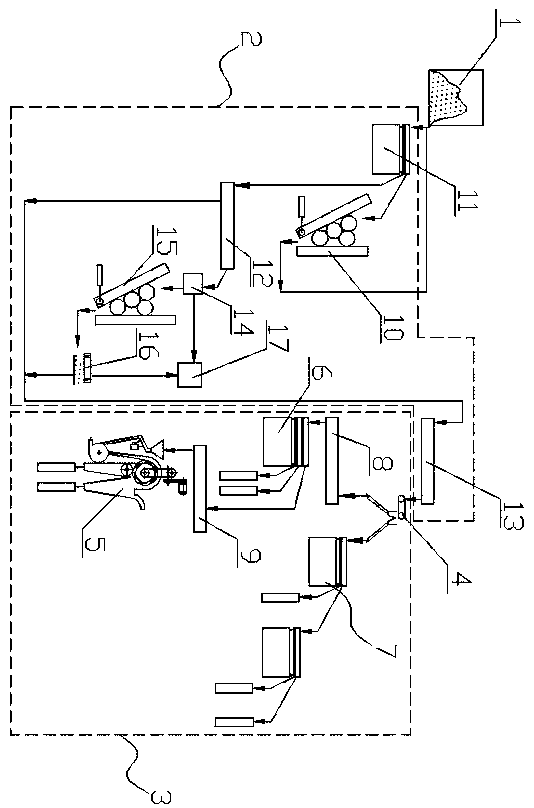

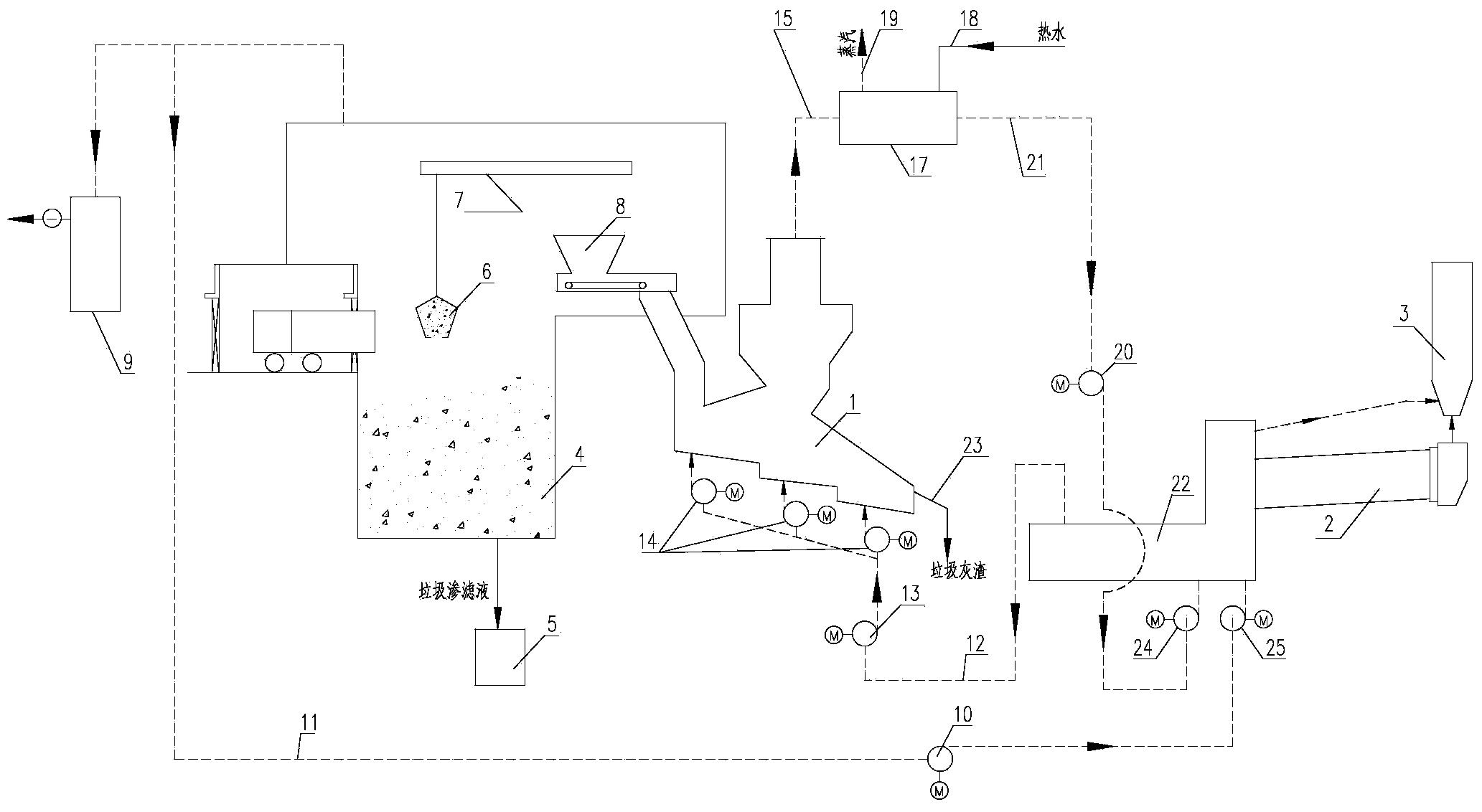

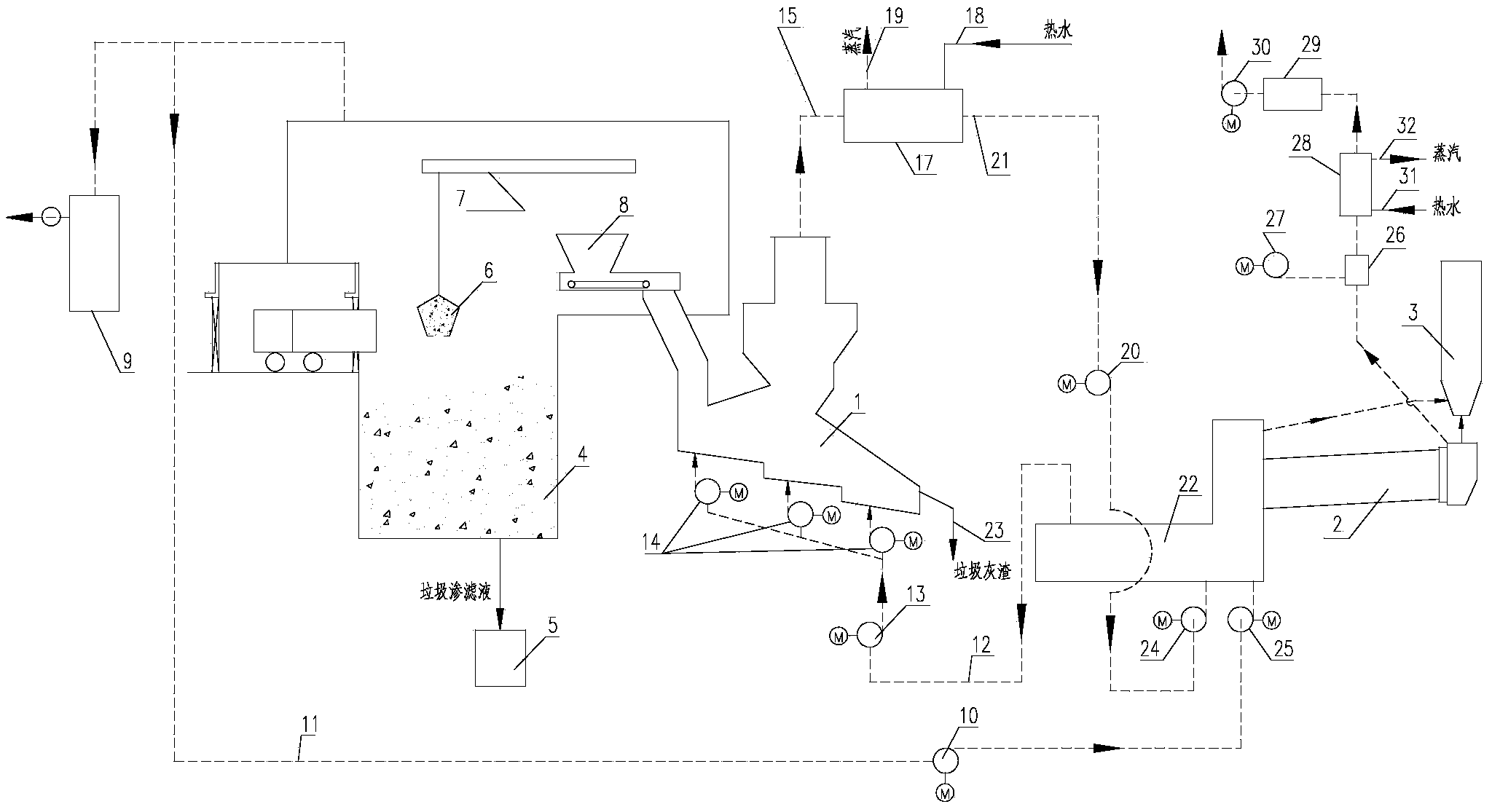

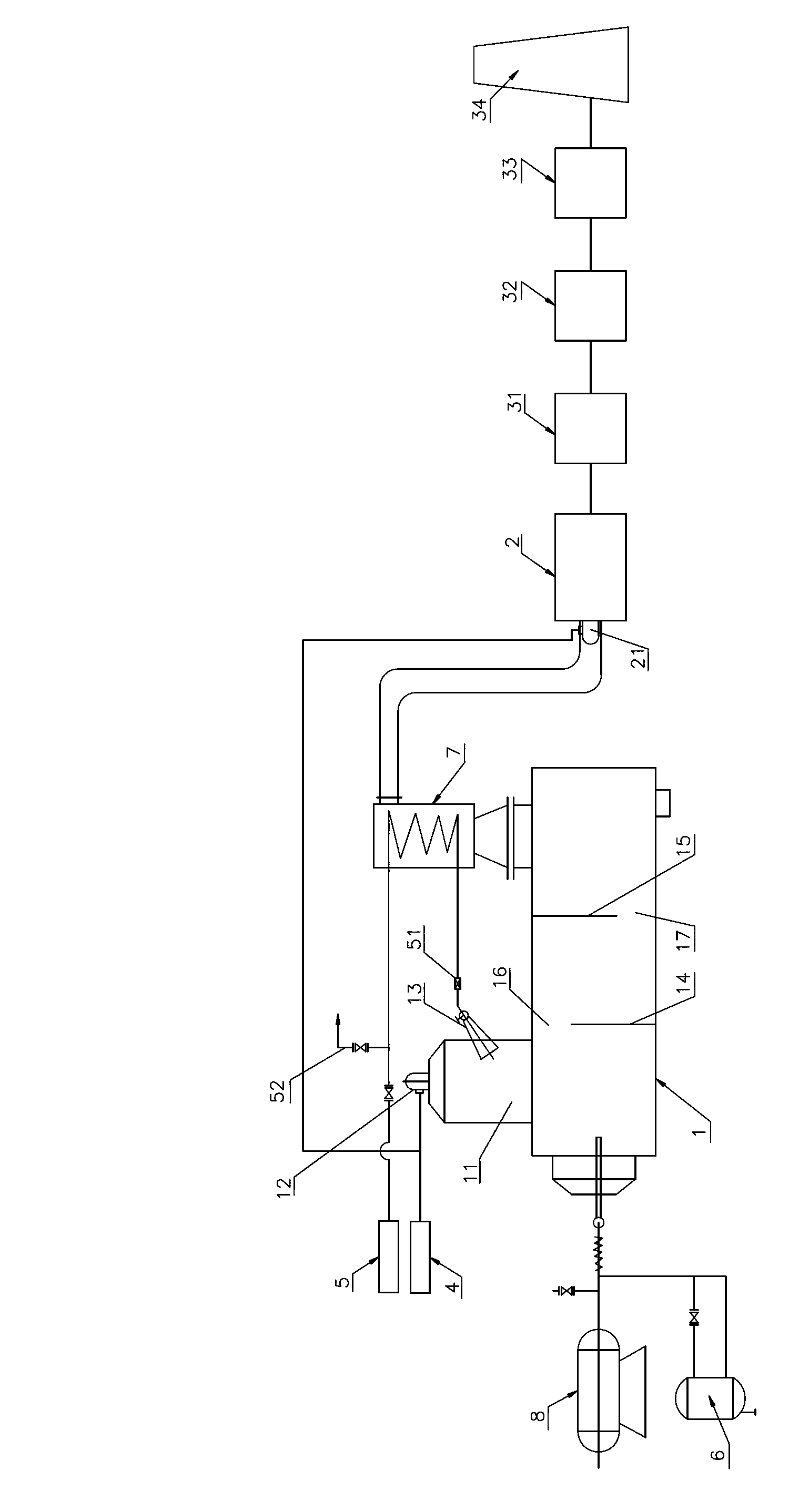

System for synergistically treating household garbage through cement kiln

ActiveCN104058615ANo leachingMigration and discharge will not occurCement productionCombined combustion mitigationHigh concentrationCement kiln

The invention relates to a system for synergistically treating household garbage through a cement kiln. The system comprises a garbage storing, incinerating and flue gas treating system, a combustion air system, a peculiar smell gas treating system, a steam boiler and power generation system, a garbage leachate treating system, a garbage clinker and fly ash treating system, a fuel combustion system and a bypass gas venting system. A garbage incinerator and a cement clinker production line are combined well, a series of characteristics of high temperature, high stability, high-concentration alkaline material, long staying time and others of a cement burning system are used for performing harmless treatment on dioxin in garbage incineration flue gas, harmful elements in garbage clinker and fly ash, garbage leachate and peculiar smell gas in a garbage storage pit, influences on the environment can completely meet the national standard requirements, and the purposes that the household garbage is harmless, the volume is reduced, and the household garbage is recycled and environmentally friendly are really achieved. The processes are simple, operation is easy and convenient, running is stable, and investment is small.

Owner:NANJING KISEN INT ENG +1

Pulp-making process using biological fermentation method

InactiveCN1395002AEliminate pollutionNo input requiredCellulose material pulpingBiotechnologyBlack liquor

The pulp-making process by using microbial fermentation process is mainly aimed at solving the problem of black liquor polluting environment, and incldues the following steps: cutting wheat (rice) straw or wood material, moistening cut wheat (rice) straw or wood material, inoculating the moistened cut wheat (rice) straw or wood material with bacteria or actino mycetes, fermenting and heating, continuously fermenting and zymolysis so as to obtain straw (wood) pulp.

Owner:姜占定

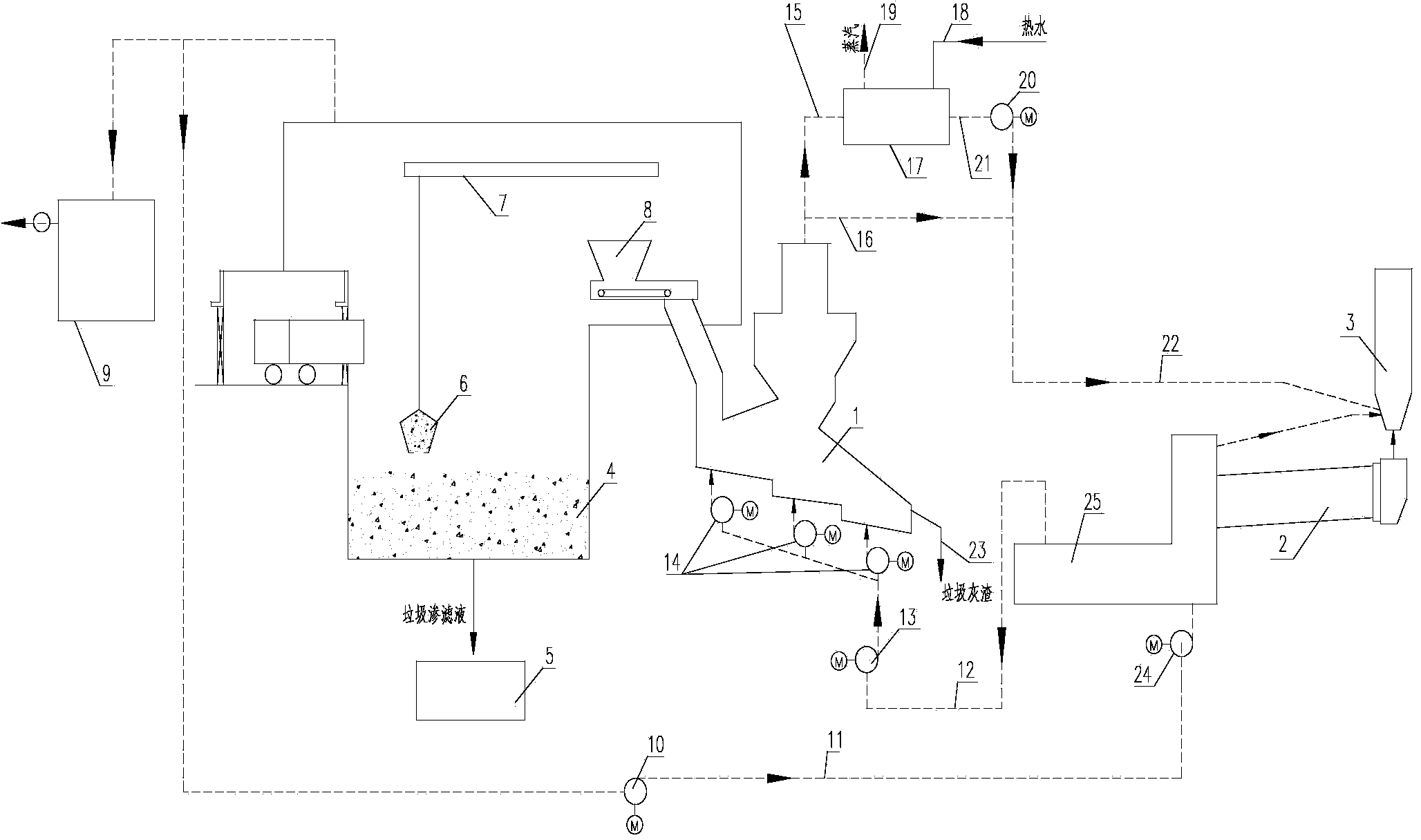

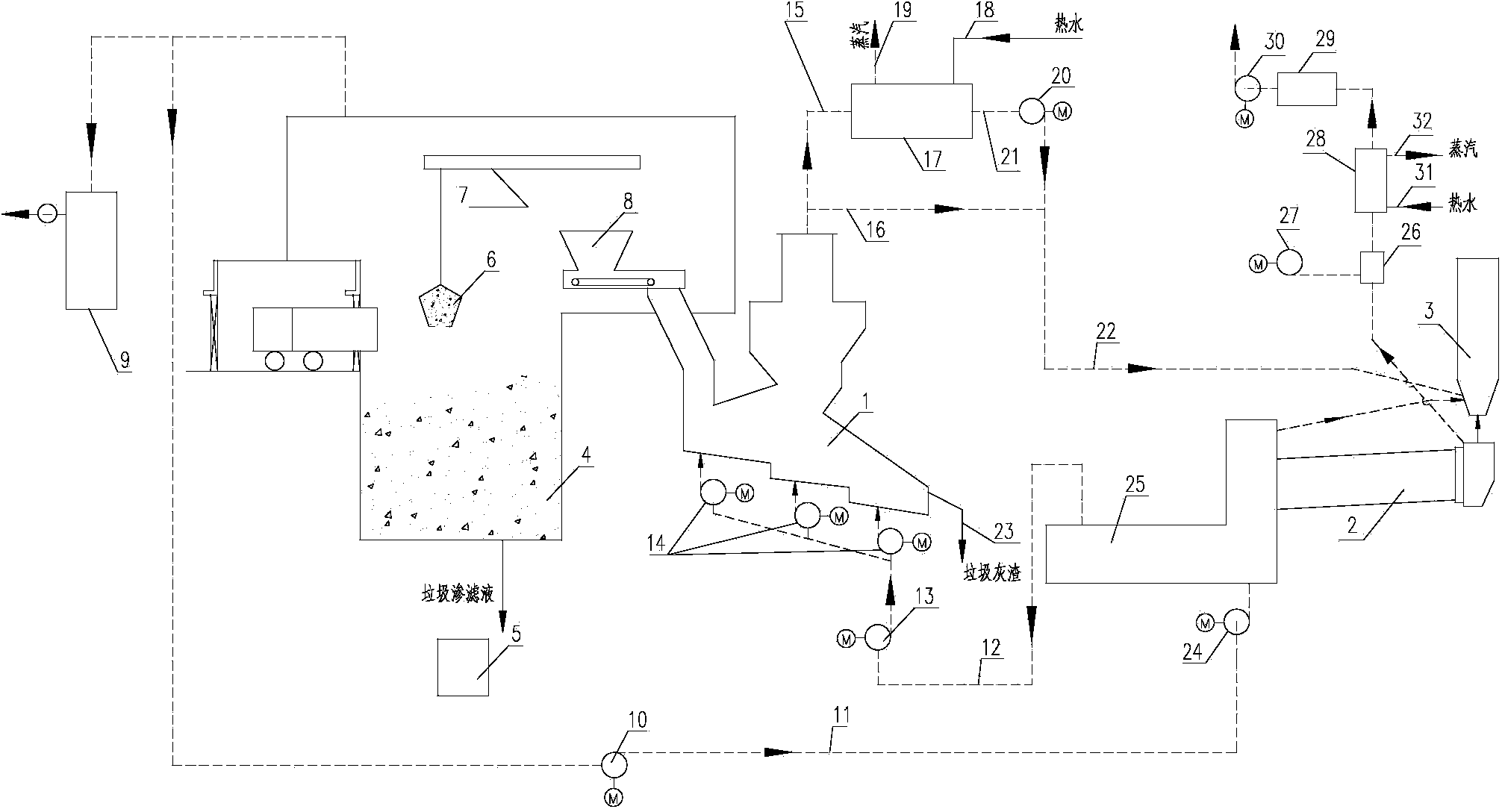

System of cement kiln for co-treatment of household garbage

ActiveCN104058614ALow calorific valueIncrease moistureSolid waste disposalCement productionVolume reductionFlue gas

The invention relates to a system of a cement kiln for co-treatment of household garbage. The system comprises a garbage incineration and flue gas treatment system, a combustion air system, a peculiar smell gas treatment system, a steam boiler system, a garbage leachate treatment system, and a garbage ash residue and flying ash treatment system. According to the system of the cement kiln for co-treatment of the household garbage, a garbage incinerator and a cement clinker production line are better combined together, the characteristics of high temperature, high stability, high-concentration alkaline materials, long standing time and the like of a cement firing system are utilized, dioxin-like harmful ingredients, garbage ash residues in garbage incineration flue gas, harmful elements and garbage leachate in flying ash and peculiar smell inside a garbage storage pit are perfectly and completely treated in a harmless mode, the environmental impact can completely meet the requirement of national standards, and the aims of harmlessness, volume reduction, recycling and environmental protection of household garbage treatment can be truly achieved. The system for the treatment of the household garbage is simple in flow path, easy and convenient to operate, stable in running, small in investment and ideal.

Owner:NANJING KISEN INT ENG +1

Comprehensive utilization method of granite

ActiveCN108940569ATo achieve the purpose of comprehensive utilizationUniform particle sizeWet separationFully developedEngineering

The invention provides a comprehensive utilization method of granite, and belongs to the technical field of mineral utilization. According to the method, two sections of crushing-screening closed-circuit processes are adopted, and sand manufacturing is achieved by utilizing a vertical impact type crushing machine; black mica is pre-separated by using a strong magnetic roller type magnetic separator; and then black quartz coarse ore, high-potassium feldspar ore and potassium-sodium mixed ore are pre-separated by adopting a color separator, moreover, the separated products are correspondingly subjected to grading and physical method purification, and the obtained final products can meet the requirements of the downstream industry. The whole production process adopts the physical method, no chemical reagents need to be added, moreover, no waste is generated, and green production is really realized. According to the comprehensive utilization method of granite, various valuable components in the granite are fully developed and utilized, the comprehensive utilization rate of resources is improved, the additional value of the products is greatly improved, social benefits and economic benefits are remarkable, and therefore, the method has a wide application prospect in the development and utilization of granite minerals.

Owner:JIANGXI UNIV OF SCI & TECH

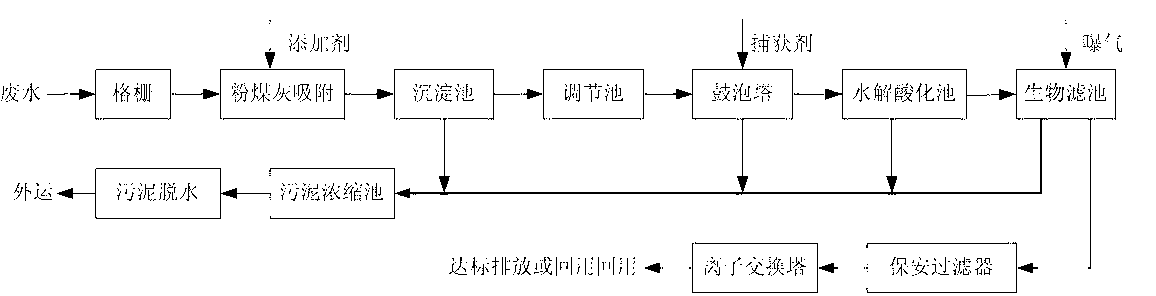

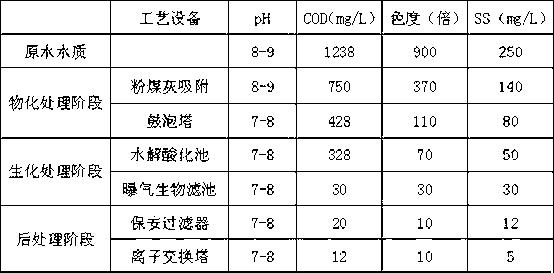

Comprehensive treatment method of dyeing wastewater

ActiveCN103204608ANo swellingEfficient removalMultistage water/sewage treatmentEnergy based wastewater treatmentGratingChemical oxygen demand

The invention relates to a comprehensive treatment method of dyeing wastewater. The comprehensive treatment method comprises the following steps of: adsorbing the wastewater by using pulverized fuel ash after passing through a grating, and adding an appropriate amount of additive in the adsorption process; filtering effluent, then adjusting the pH value of the filtered effluent, adding the effluent to a bubbling tower to further carry out decoloring treatment; and adding the decolored effluent to a hydrolysis acidification pool to carry out anaerobic treatment, carrying out further biochemical treatment by using a biological aerated filter, carrying out biological oxidation and intercepting suspended solids, and therefore a subsequent secondary sedimentation tank is saved; and finally, carrying out advanced treatment by using a security filter and an ion-exchange column, wherein the effluent can be close to the recyclable requirement. The comprehensive treatment method can be used for effectively removing fine suspended solids (SS), COD (Chemical Oxygen Demand) and chromaticity in the dyeing wastewater, and the removal rate of the SS, COD and chromaticity can reach more than 98 percent; the comprehensive treatment method has the advantages of small occupied area, low investment, simpleness in operation, low energy consumption, operation stability, no sludge bulking and the like; and in addition, the purposes of treatment of wastes with processes of wastes against one another and comprehensive utilization are achieved, the effluent quality is favorable, and the requirement of the water quality of reuse water for production can be met.

Owner:浙江一清环保工程有限公司

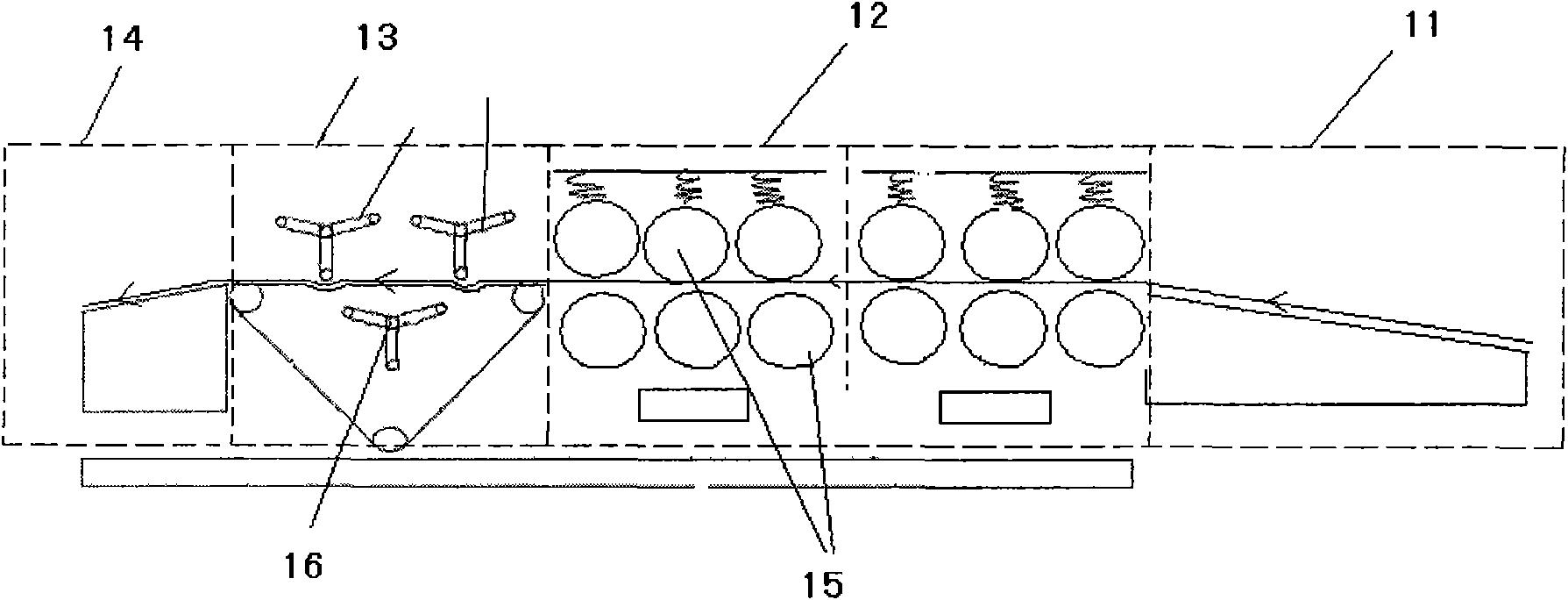

Processing system for processing hemp into hemp fiber

InactiveCN104562217AReduce stress and difficultyReduce processing timeMechanical impurity removalTextile/flexible product manufactureHemp fiberFineness

The invention relates to a hemp fiber manufacturing production line, in particular to a processing system for processing hemp into hemp fiber. The processing system for processing the hemp into the hemp fiber comprises devices for arranging hemp, degumming, dividing fiber and water washing, rinsing and softening, drying, softening and oiling, permeating and health maintaining, crush cutting and teasing, and combing and arranging; a degumming device comprises a mechanical degumming device, a biological degumming device and a high-temperature scouring-bleaching degumming device, and the device is special; a yarn hanging rack is composed of a hollow post and a plurality of hollow beams in a connecting mode, the hollow beams are provided with a plurality of hanging rods, and a plurality of holes are formed in the sides of the hanging rods; the crush cutting and teasing use a drafting roller set and a snapping roller set, and the drafting roller set and snapping roller set run in differential speeds and pressurize simultaneously. The combing and arranging use a round comb and a top comb to comb and a pulling vehicle to pull, along the rotating direction, the density of gill bars is increased gradually, and the fineness is reduced gradually. The processing system for processing the hemp into the hemp fiber changes a traditional hemp processing device, improves the long hemp yield and facilitates subsequent processing, and the produced hemp fiber is stable in quality.

Owner:王学钢

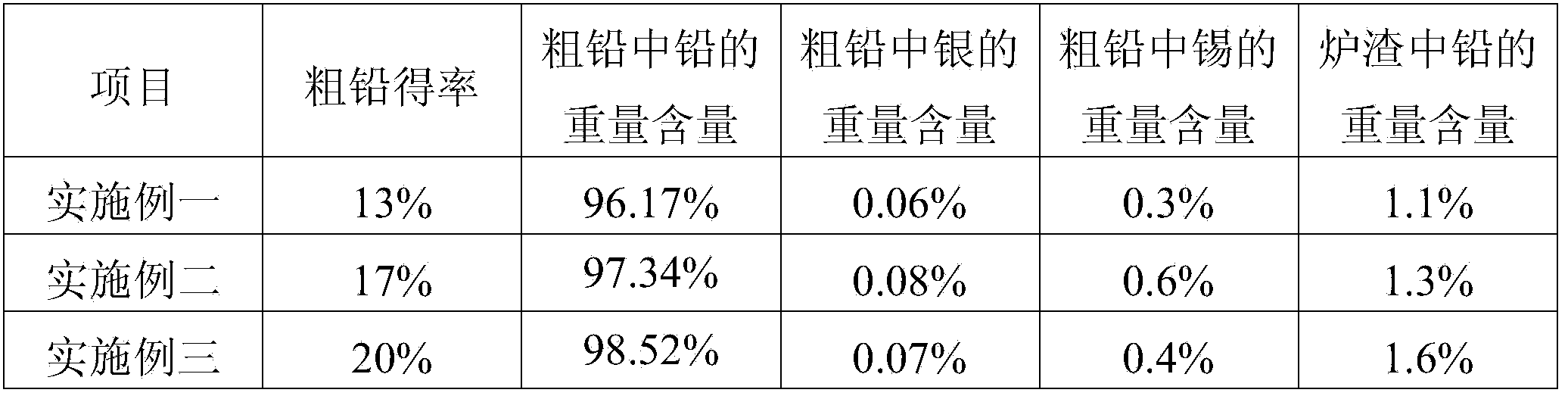

Comprehensive recovery method of waste CRT (Cathode Ray Tube) cone glass

InactiveCN103409636AEfficient extractionEfficient use ofProcess efficiency improvementRecovery methodIngot casting

The invention relates to a comprehensive recovery method of waste CRT (Cathode Ray Tube) cone glass and belongs to the technical field of environmental protection. The comprehensive recovery method comprises the following steps: a, mixing, namely weighting waste CRT (Cathode Ray Tube) cone glass, lead-containing materials with the lead content of 3-60 percent and coke, and uniformly mixing to obtain a primary mixture; b, detecting and smelting, namely, detecting the weight contents of FeO, SiO2, CaO, MgO, Zn, S and Al2O3 in the primary mixture, and feeding to a smelting device after the weight contents in the primary mixture are qualified, and smelting to respectively obtain smelt lead, slag and dust; and c, carrying out ingot casting on the lead liquid to obtain a coarse lead finished-product. The comprehensive recovery method disclosed by the invention has the beneficial effects that the waste CRT (Cathode Ray Tube) cone glass can be effectively and comprehensively utilized and no environmental pollution is caused.

Owner:开远市龙腾冶炼厂

Method for recovery processing sulfur-containing mixed waste gas in production of viscose

InactiveCN103772250AAchieve the purpose of reuseEfficient use ofCarbon disulfideOrganic chemistrySocial benefitsExhaust fumes

The invention relates to a method for recovery processing sulfur-containing mixed waste gas in the production of viscose, which belongs to the technical field of the treatment of sulfur-containing waste gas in the production of viscose. The invention provides a novel technical route for the existing waste gas treatment situation of the viscose production enterprise, the sulfur-containing waste gas of low concentration is pretreated firstly, then the sulfur-containing waste gas is selectively absorbed by adopting the spraying absorption technology, then the absorption liquid is treated, and finally a product with high cost performance is obtained. The technical route is high in industrialization degree, the mixed waste gas consisting of low-concentration H2S, CS2, vast air and little solid waste in the production process of viscose industry can be effectively treated in time, certain economic benefit and social benefit also can be obtained, the technical feasibility and economical feasibility are good, and the sustainable development requirement of the society can be met.

Owner:YIBIN GRACE +2

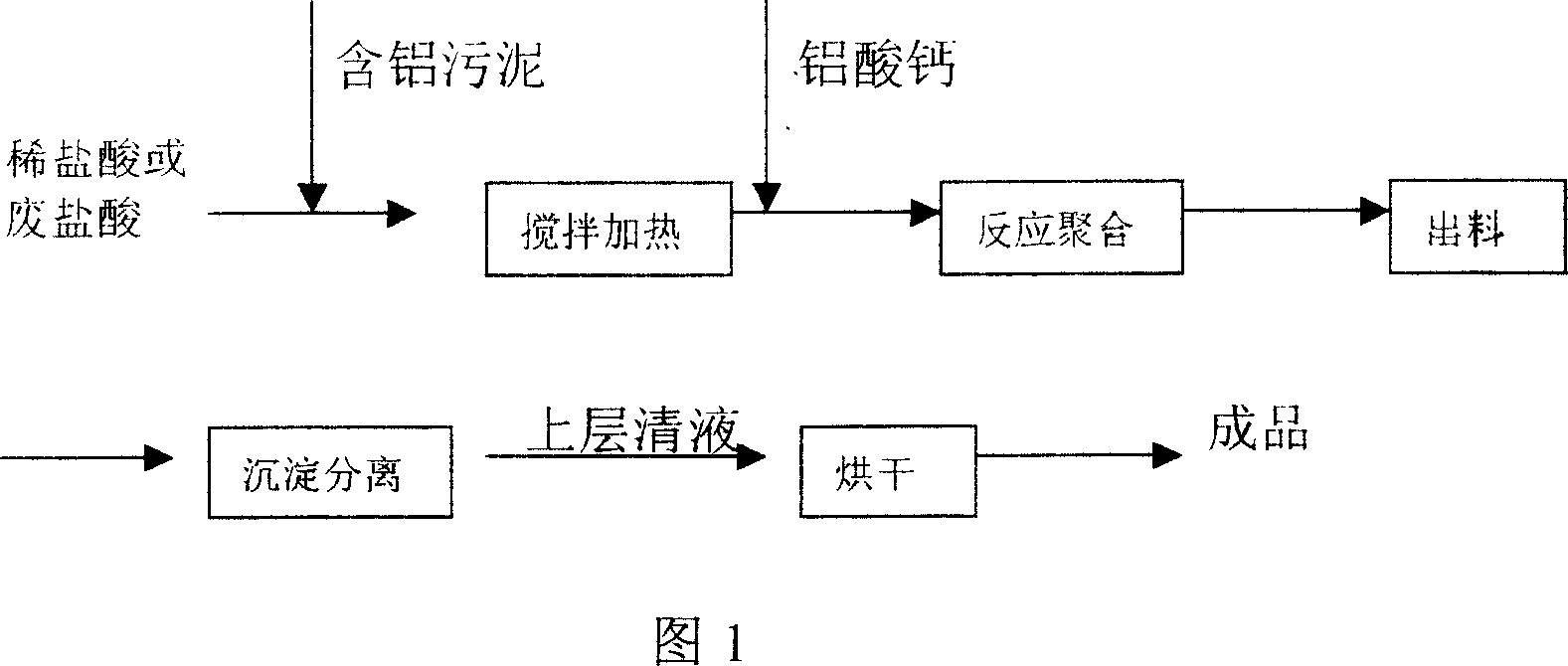

Method of producing aluminium polychloride using aluminium hydroxide mud

InactiveCN1948156ATo achieve the purpose of comprehensive utilizationImprove hygieneAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminium chlorohydrate

The present invention relates to a method for producing aluminium polychloride by utilizing aluminium hydroxide sludge. Said method includes the following steps: firstly, adding dilute hydrochloric acid or waste hydrochloric acid into reaction tank, then adding aluminium hydroxide sludge, stirring to make reaction and dissolvation, adding calcium aluminate powder and adding additive, make continuous reaction and dissolvation, heat-insulating, making natural precipitation to obtain supernatant fluid, said supernatant fluid is liquid aluminium polychloride; making the liquid aluminium polychloride be fed into a high-level tank and added into a pool under the drying drum, making the drying drum be contacted with said liquid aluminium polychloride, and making the liquid aluminium polychloride be adsorbed on the surface of said drum, utilizing scraper blade in the front of said drum to scrape off said absorbed liquid aluminium polychloride from the drum so as to obtain the solid aluminium polychloride.

Owner:童益

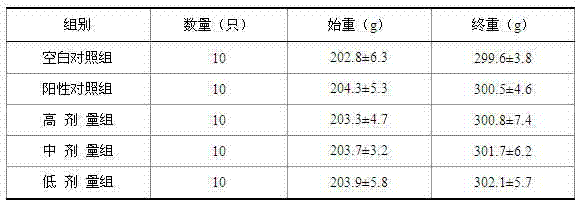

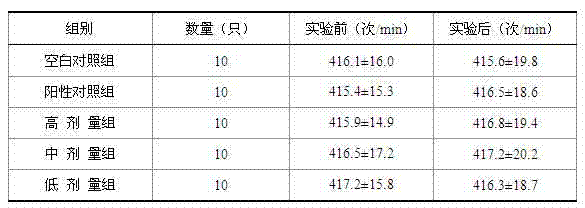

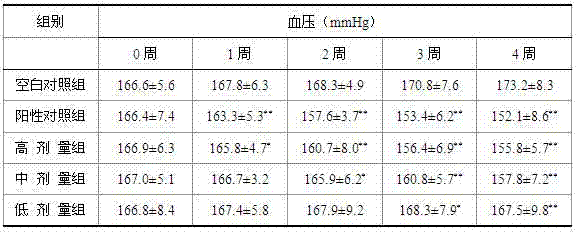

Method for preparing seaweed product for reducing blood pressure via step-by-step extraction and bioconversion coupling

ActiveCN104256252ATo achieve the purpose of comprehensive utilizationImprove high-value utilizationSugar food ingredientsHydroxy compound active ingredientsBiotechnologyFucoidan

The invention relates to a health care product for assisting blood pressure reduction, provides a method for preparing a health care seaweed product for assisting blood pressure reduction via step-by-step extraction and bioconversion coupling, and belongs to the field of deep processing of ocean foods. The method is carried out by taking high-quality seaweeds as raw materials via an ultrasonic circulation step-by-step extraction process and a bioconversion coupling preparation technology. The preparation method sequentially comprises the following steps: carrying out pretreatment of raw materials, alcohol extraction of mannitol, acid extraction and alcohol precipitation of sodium alginate and fucoidan, bioconversion and ultrafiltration so as to obtain physiological active components for reducing blood pressure; and scientifically blending the active components. According to the method, a large quantity of seafood seaweeds in China are deeply processed and comprehensively utilized so as to obtain five products, namely mannitol, sodium alginate, fucoidan, seaweed dietary fibers and seaweed antihypertensive peptides; and the five products are scientifically blended so as to develop a series of novel functional seaweed products for reducing blood pressure reduction, wherein the series of functional seaweed products have obvious functions of assisting blood pressure reduction. The ACE inhibitory activity IC50 of the seaweed product is within 0.68mg / g to 1.15mg / g, so that the blood pressure of an SHR (Spontaneously Hypertensive Rat) can be obviously lowered (-12.4 mmHg to -17.5mmHg).

Owner:FUZHOU HAILIN FOODSTUFF

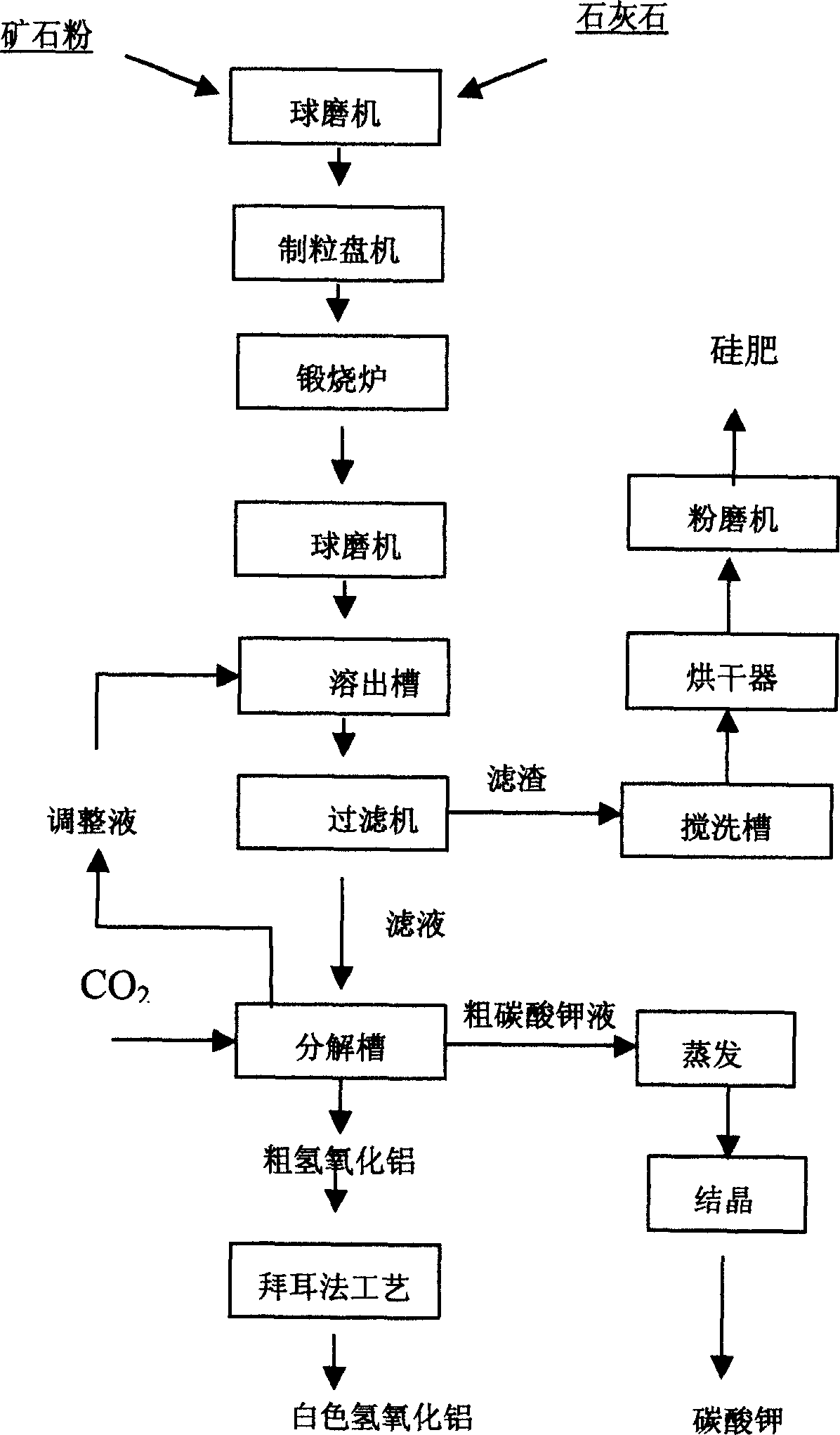

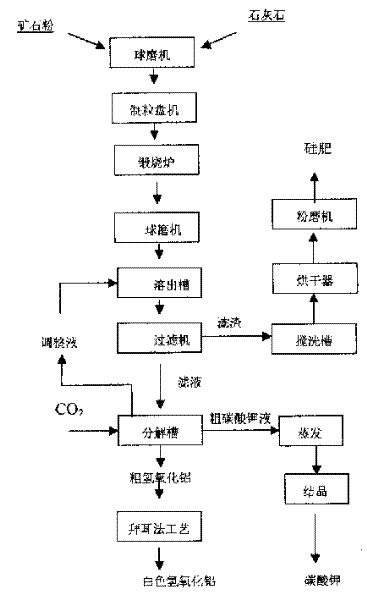

Formula and technique for extracting potassium carbonate and aluminum hydroxide and preparing siliceous fertilizer using slate with rich kalium

InactiveCN1603234AIncrease economic value addedProtect the environmentAlkali metal carbonatesAluminium oxides/hydroxidesAluminium hydroxidePotassium

The invention relates to a compounding recipe and technology to distill potassium carbonate and aluminum hydroxide by potassium-rich slate and to produce siliceous fertilizer. It belongs to fertilizer producing field. Its feature is that putting the potassium-rich slate ore and limestone into ball mill, cuber, rotary kilncalcnaton furnace, ball mill, digestion tank and filter according to calcium-silicon mol ratio. Then, part of rough potassium carbonate is used to confect correction liquor, and the other is used to gain potassium carbonate after concentration and crystallizing. The leached residue is rough potassium hydroxide, and pure potassium hydroxide would be gained by Bayer process technology. And other part is used to gain siliceous fertilizer after passing washer tank, drying apparatus and pulverizer. The invention could make the extraction rate of alumina reach to over 60% and that of kali reach to over 80%. It can transform the silicon element into siliceous fertilizer. The invention would not produce exhausted water and waste residue. Thus, the purpose of comprehensive utilization of resource would be realized.

Owner:包头市科技开发研究院

A method for reprocessing and comprehensive utilization of red mud

ActiveCN102295396ASimple methodTechnical parameters are easy to controlSludge treatmentRed mudMagnetic separator

The invention discloses a reprocessing and comprehensive utilization method of red mud, comprising the following steps: (1) carrying out mashing on red mud, and carrying out artificial mineral dressing on heavy mineral to respectively obtain coarse sand and mortar; (2) drying the coarse sand, then carrying out magnetic separating to respectively obtain quartz sand and level 1 magnetic material; (3) carrying out magnetic separating on the level 1 magnetic material to respectively obtain magnetite powder and tailing 1; and (4) putting the mortar in a magnet separator for magnetic separating to respectively obtain fine iron ore and tailing 2. The method is simple and practicable and has the advantages of easily controllable technical parameters, little energy consumption and low cost, can process more than 100 Mtpa per year, reduce the discharging capacity of red mud by 35-70 % and reduced the production cost of alumina. The main products of the method are magnetite powder and quartz, and the obtained two tailings can be used in preparing dry cement or in damming, so that the purpose of comprehensive utilization of red mud is achieved.

Owner:中铝山东有限公司

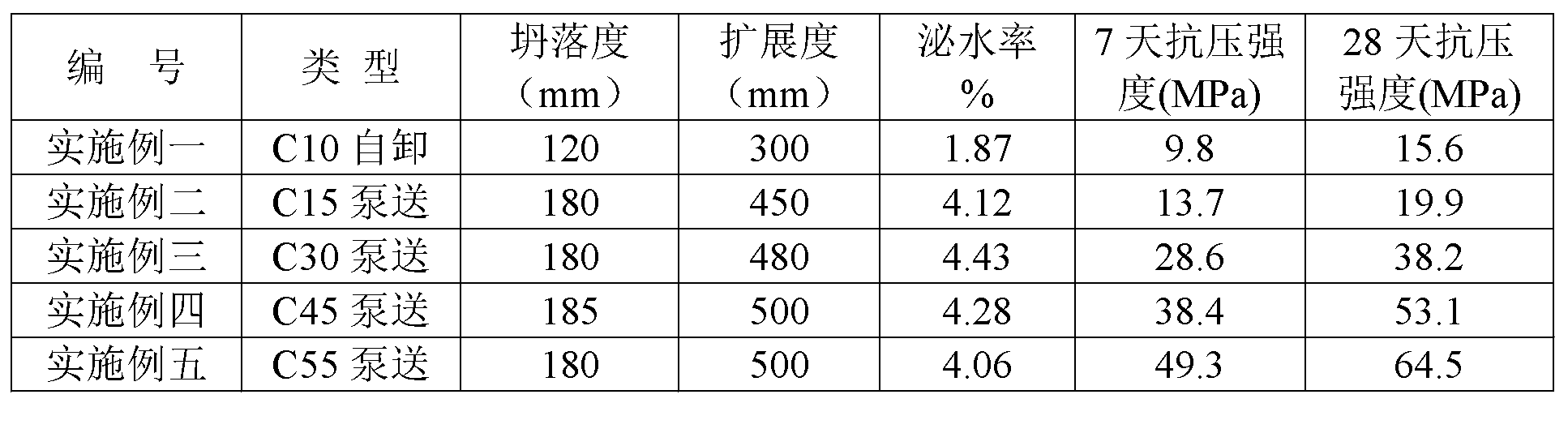

Concrete taking green mud and white mud as admixtures and preparation method for concrete

ActiveCN103011706ASolve land occupationSolve environmental pollutionSolid waste managementSlagWater reducer

The invention relates to concrete taking green mud and white mud as admixtures and a preparation method for the concrete. The concrete is prepared by uniformly stirring gel, sand, stone, water and a water reducing agent. The gel consists of paper pulp waste slag, cement and other admixtures; the paper pulp waste slag is one or the mixture of the green mud and the white mud; and other admixtures are one or more than two of waste basalt powder, coal ash and blast furnace mineral slag powder. By the concrete, the problems of occupation of lands by the paper pulp waste slag and environment pollution are solved; the aim of comprehensively using the green mud and the white mud is fulfilled; environment friendliness, energy conservation and emission reduction are facilitated; the concrete is high in workability, high in expandability and low in bleeding and can meet a requirement on C10-C55 concrete; a production process is simple; the cost is low; and the preparation method is a green mud and white mud comprehensive using industrial method with an extremely good prospect.

Owner:HAINAN LANDAO ENVIRONMENTAL PROTECTION IND

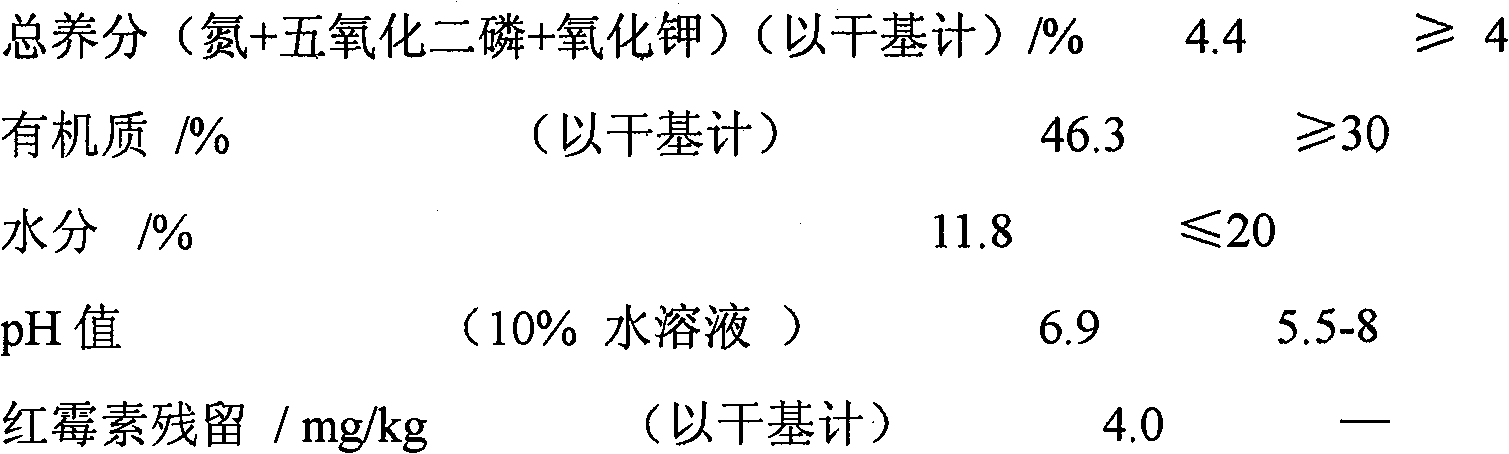

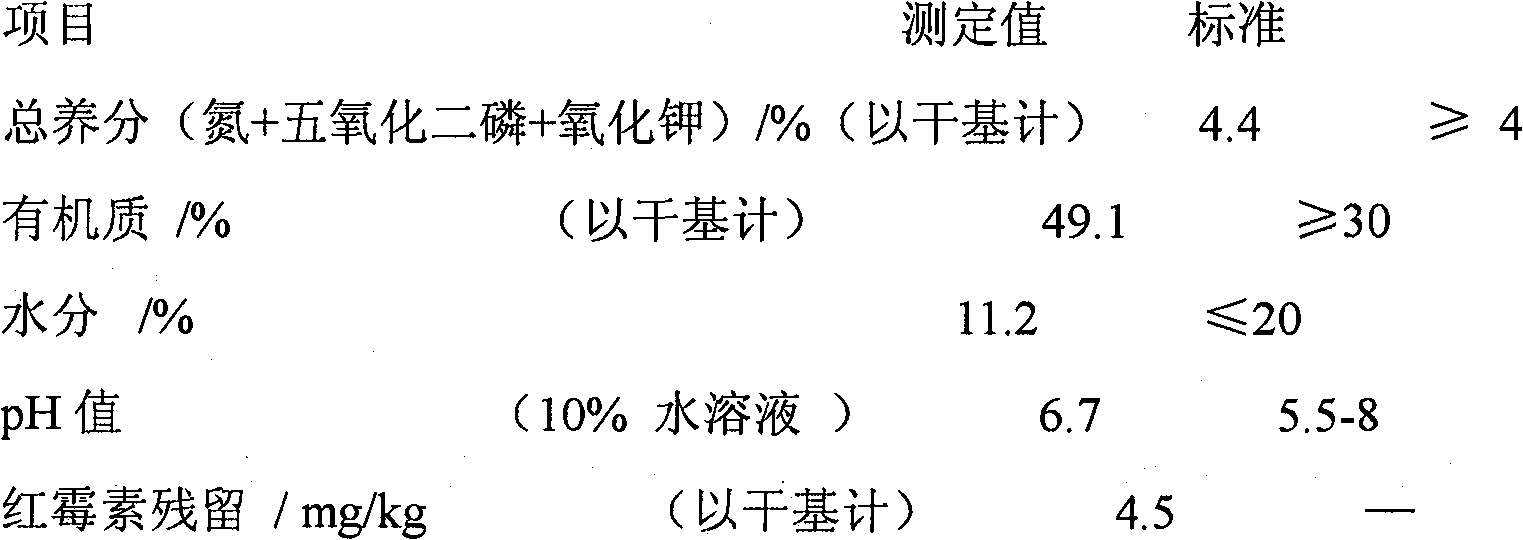

Method for performing anaerobic innocent treatment on erythromycin mushroom residue and using erythromycin mushroom residue for producing organic fertilizer

InactiveCN103232292AEasy to operateImprove processing efficiencyFertilizer mixturesMushroomChemistry

The invention discloses a method for performing anaerobic innocent treatment on erythromycin mushroom residue and using the erythromycin mushroom residue for producing an organic fertilizer. The method comprises the following steps of: mixing the erythromycin mushroom residue with erythromycin production wastewater, and controlling the concentration of the mushroom residue to be 10-20 kg / m<3>; then performing anaerobic reaction in a reaction system having a pH value of 6.5-8.0 for 36-72 hours at a temperature of 28-68 DEG C; after the reaction, precipitating, and treating the erythromycin mushroom residue by virtue of a biological anaerobic fermentation technology, reducing the erythromycin residue in the mushroom residue to be less than 10 mg / kg, and realizing the innocent treatment simultaneously; and then adding auxiliary materials, mixing, stirring, granulating, and drying to obtain the organic fertilizer, wherein the organic fertilizer is recycled to achieve the purpose of comprehensive utilization. The method is simple to operate and high in treatment efficiency, thus being capable of realizing large-scale treatment; and the method is remarkable in economic benefits and social benefits.

Owner:四川千业环保产业发展有限公司

Method for producing ferro-aluminium composite water purifying agent using aluminium hydroxide mud

InactiveCN101070202ANot easy to secondary pollutionGood for sanitationSludge treatmentWater/sewage treatment by neutralisationChemistryAluminium salts

This invention relates to a method of using aluminium hydroxide sludge to produce aluminum-iron compound purifying agent, belongs to sewage disposal technosphere. This method mostly add waste pickle liquid containing iron to reaction tank, gradually add aluminium hydroxide sludge, at ordinary temperature whip for reaction, make aluminium hydroxide sludge by step dissolve and generate liquid compound aluminum iron purifying agent; after precipitation, supernatant liquid is finished product of liquid compound aluminum-iron purifying agent. This invention recycles waste vitriol or hydrochloric acid containing iron, in favor of environmental health.

Owner:童益

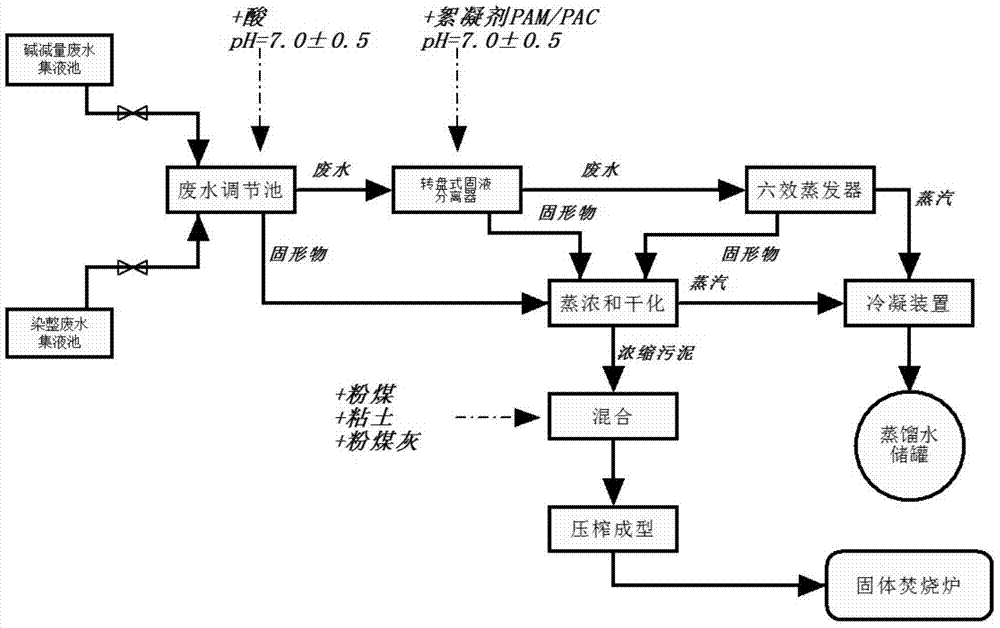

Wastewater zero discharge method in manufacturing process of island superfine fiber synthetic leather

InactiveCN103693792ASolve the technical bottleneck of zero emissionQuality improvementSludge treatment by de-watering/drying/thickeningBiofuelsFiberAluminium chlorohydrate

The invention discloses a wastewater zero discharge method in a manufacturing process of island superfine fiber synthetic leather. The method comprises the following steps: merging an alkali-minimization wastewater and a dyeing wastewater into a wastewater regulating reservoir, or merging the alkali-minimization wastewater into the wastewater regulating reservoir; adding acid to the wastewater regulating reservoir to form a solid matter; transferring the wastewater after the solid matter is cleaned into a turntable solid-liquid separator; adding a polyacrylamide flocculant and a polyaluminium chloride flocculant; evaporating the solid matter and the sludge obtained by solid-liquid separation in an evaporation tank, and simultaneously collecting distilled water in a condensation manner; transferring the wastewater from solid-liquid separation into a multi-effect evaporator to evaporate, and collecting distilled water by condensation; merging the residual residue in the evaporator into a sludge concentrating tank to continue to process. The production of the island superfine fiber synthetic leather is taken as a basic system, and is combined with collection, treatment and comprehensive utilization technologies of the production wastewater and the solid matter, the technical bottlenecks of wastewater zero discharge in the production process is solved, and the island superfine fiber synthetic leather which is friendly to environment and high in quality can be produced.

Owner:FUJIAN KELISHENG SUPERFINE FIBER

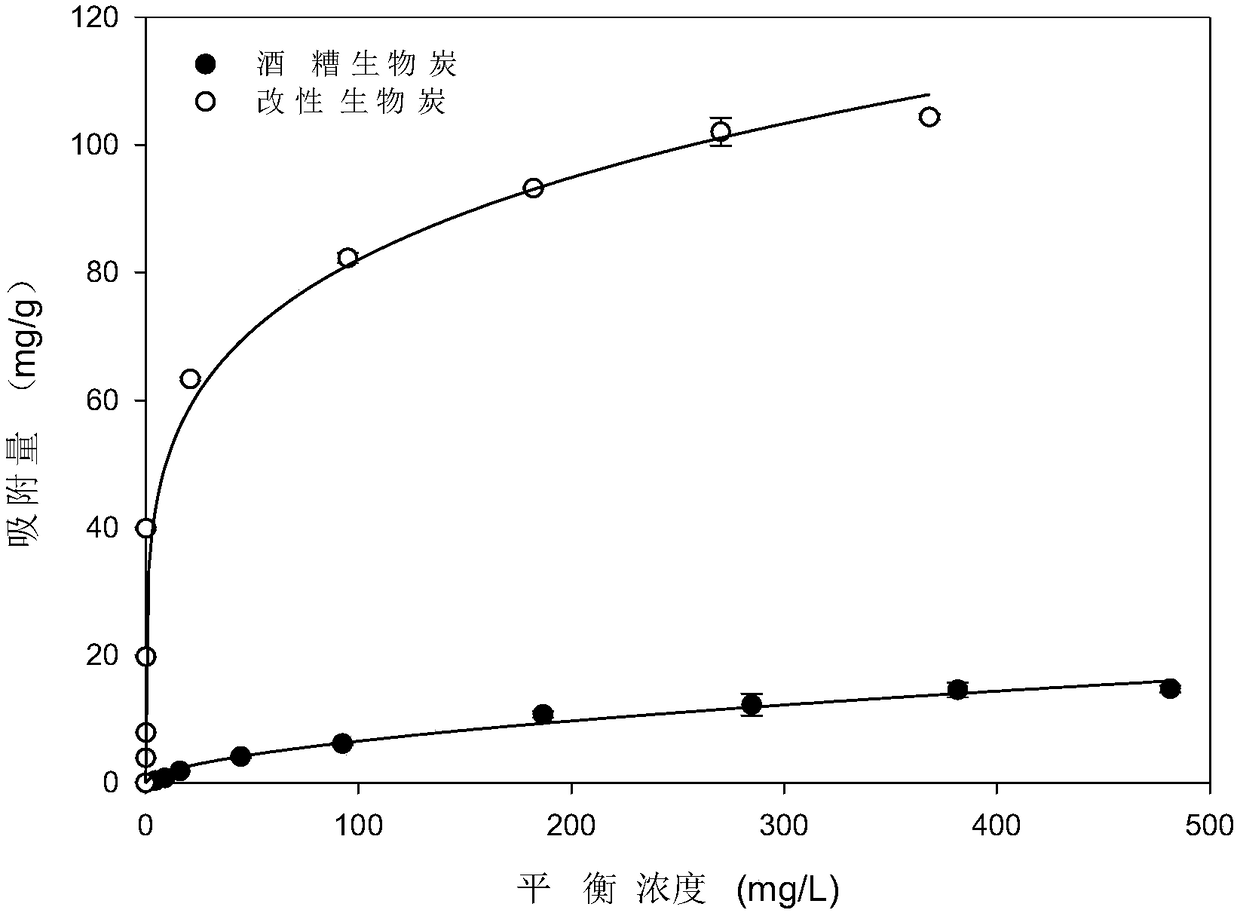

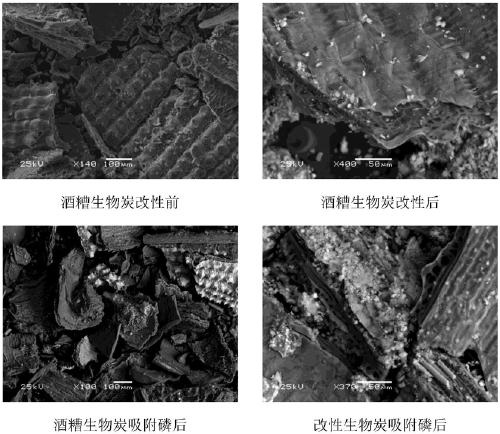

Phosphogypsum modified biochar method and application

ActiveCN108927109AImprove adsorption capacityWide variety of sourcesOther chemical processesWaste water treatment from food industryEutrophicationPhosphogypsum

The invention discloses phosphogypsum modified biochar and an application thereof. Preparation of the phosphogypsum modified biochar comprises the following steps: (1) drying biomass to remove water,grinding and sieving for standby application; (2) drying phosphogypsum mined back from a phosphogypsum stack for standby application; (3) taking phosphogypsum and the biomass powder in a proportion of(1-5):10 by weight, mixing evenly, adding water, fully stirring, fully mixing the phosphogypsum and the biomass powder evenly, and drying to obtain modified biomass for standby application; and (4) carrying out pyrolysis of the modified biomass under anaerobic or anoxic conditions to produce modified biochar, namely phosphogypsum modified biochar. The problems of comprehensive utilization of a large amount of solid waste-phosphogypsum and eutrophication of a water body in a sewage treatment process, as well as the problems of complex conventional modification technical craft, tedious reactionprocess, high cost and the like in China at present can be effectively solved,.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

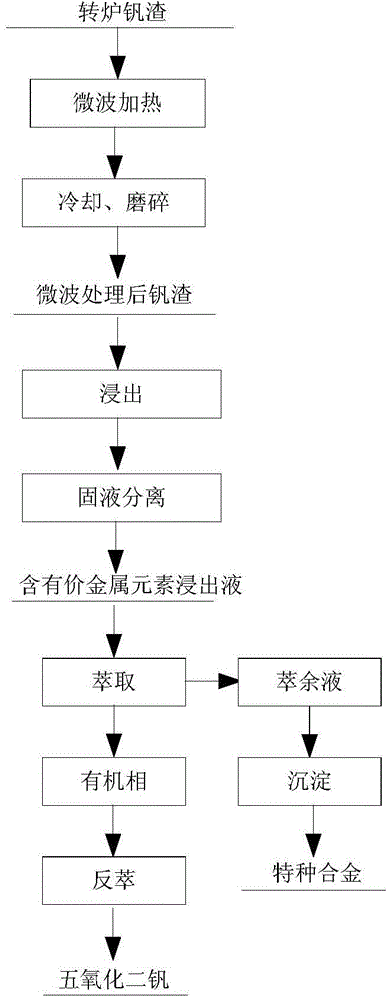

Method for extracting valuable metal in vanadium containing material by microwave heating preprocessing

The invention provides a method for extracting valuable metal in a vanadium containing material by microwave heating preprocessing to overcome the shortcoming existing in a method for vanadium containing material microwave preprocessing in the prior art and belongs to the technical field of colored metallurgy. The method comprises the steps that the vanadium containing material is subjected to solid phase microwave heating, heating time is 10-20 min, heating temperature is 150-450 DEG C, and then the heated vanadium containing material is taken out and ground until the granularity is smaller than or equal to 200 meshes; the vanadium containing material subjected to microwave processing is added into a sulfuric acid solution for leaching, then, liquid-solid separating is carried out, and leachate containing the valuable metal of vanadium, iron, manganese, chromium and the like is obtained; the leachate is subjected to extraction and re-extraction, vanadium in the leachate is separated, and a vanadium product is obtained by recycling; and iron, manganese, chromium and the like in the leachate are obtained by separating through a coprecipitation method and are used as raw materials for preparing special alloy. According to the method, the production cost for extracting valuable metal elements from the vanadium containing material can be lowered, additive loss and energy loss are lowered, and the multipurpose utilization rate of the vanadium containing material, especially the vanadium titano-magnetite resources is improved.

Owner:NORTHEASTERN UNIV

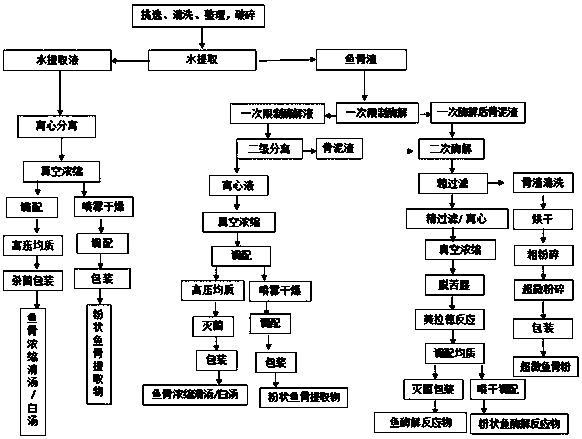

Method for preparing seafood seasoning material based on water extraction and secondary enzymatic hydrolysis

ActiveCN108514096ATo achieve the purpose of comprehensive utilizationReasonable technical solutionSugar food ingredientsYeast food ingredientsMaillard reactionFiltration

The present invention provides a method for preparing a seafood seasoning material based on water extraction and secondary enzymatic hydrolysis. The method is as follows: fish bones and other by-products produced in fish processing processes are subjected to the water extraction; then the secondary enzymatic hydrolysis is utilized to obtain a water extract, a primary enzymatic hydrolysate and a secondary enzymatic hydrolysate; the water extract and primary enzymatic hydrolysate are prepared into fish bone concentrated clear soup and fish bone concentrated white soup respectively by filtration, centrifugation, concentration, preparation, homogenization, sterilization and other steps; spray-drying is conducted to prepare a powdered fish bone extract; the secondary enzymatic hydrolysate is prepared into a fish enzymatic reaction product by filtration, centrifugation, concentration, debittering, blending, Maillard reaction, sterilization and other steps; or the spray-drying is conducted to prepare a powdered fish enzymatic reaction product; and the fish bones after the enzymatic hydrolysis can be prepared into fish bone meal by drying and superfine grinding. The technical scheme is reasonable; the extraction efficiency is high; the prepared product has good flavor and wide applications; and the purpose of the comprehensive utilization of the fish bone by-products is achieved.

Owner:BOHAI UNIV

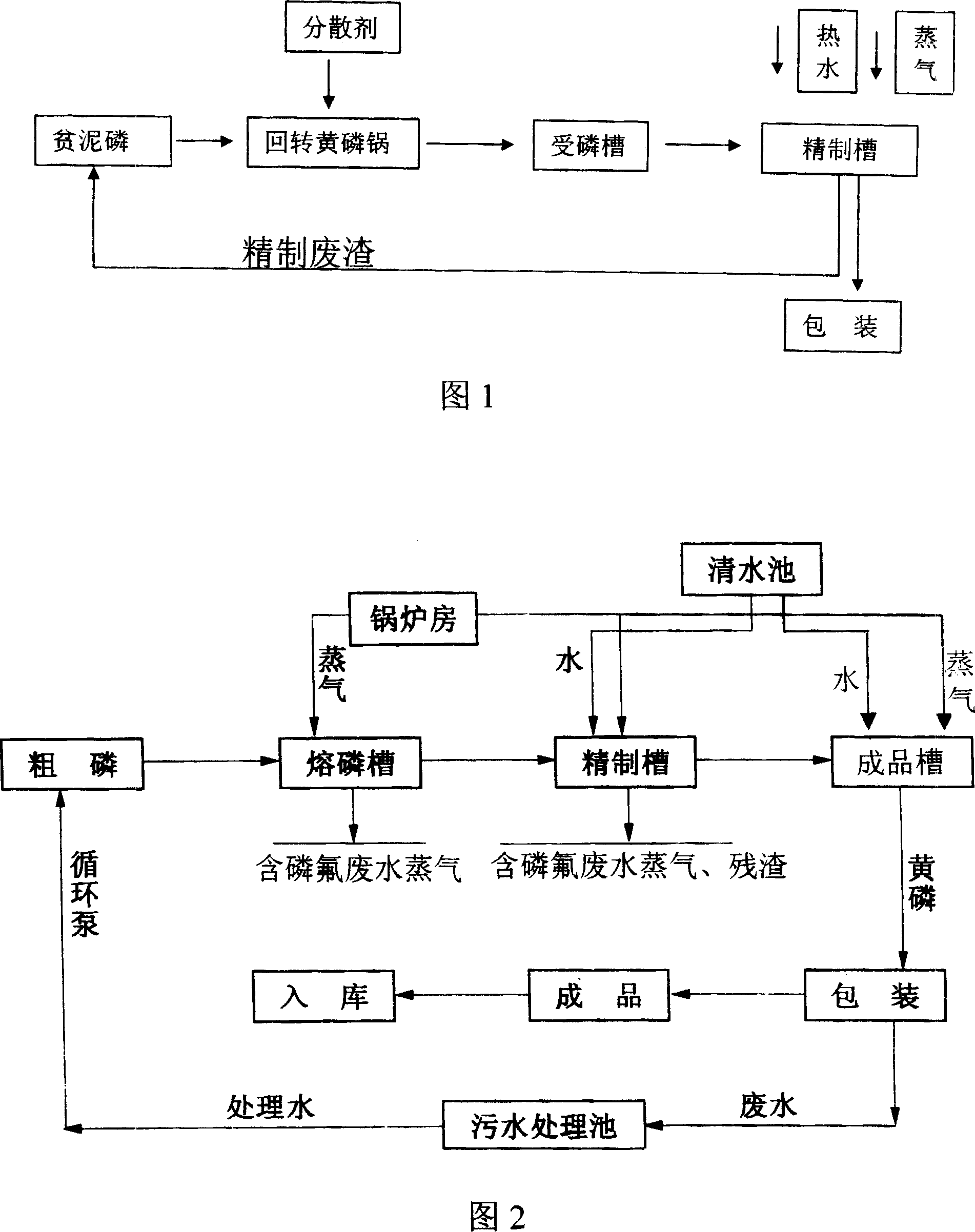

Mud phosphor recovery and refining method

The invention discloses a new recycling and refining method of sludge phosphor, which comprises the following steps: placing sludge phosphor in the rotary phosphor distilling furnace to recycle phosphor; adding dispersant; transmitting rough phosphor into phosphor-fused groove; inputting steam in the phosphor-fusing groove to remove fluorine; transmitting phosphor into refined groove; aerating hot water; heating to bleach; transmitting phosphor into product groove to obtain the yellow phosphorus.

Owner:胡晓丽 +1

Method for eliminating calcium sulphate with bittern

InactiveCN101172686AIncreased sodium chloride contentLess quantityWater/sewage treatmentCommon-ion effectSalting out

The invention provides seawater processing technology, in particular to a method of removing calcium sulphate by use of brine. 5 to 13 degrees Be brine is added with industrial crude salt to make the brine concentration to 17 to 25 degrees Be and dissolve the calcium sulphate. According to the rule of brine dissolving salt and the salting-out theory as well as the common ion effect theory, the composition of the(5 to 13 degrees Be) brine is changed by adding the industrial crude salt to increase the sodium chloride content in the brine so as to increase the brine concentration up to 17 to 25 degrees Be, thereby reducing the solubility of the calcium sulphate and dissolving most of the calcium sulphate; besides, the dissolved brine can be directly used for producing the vacuum refined salt.

Owner:ENG TECH INST CO LTD OF CNSIC

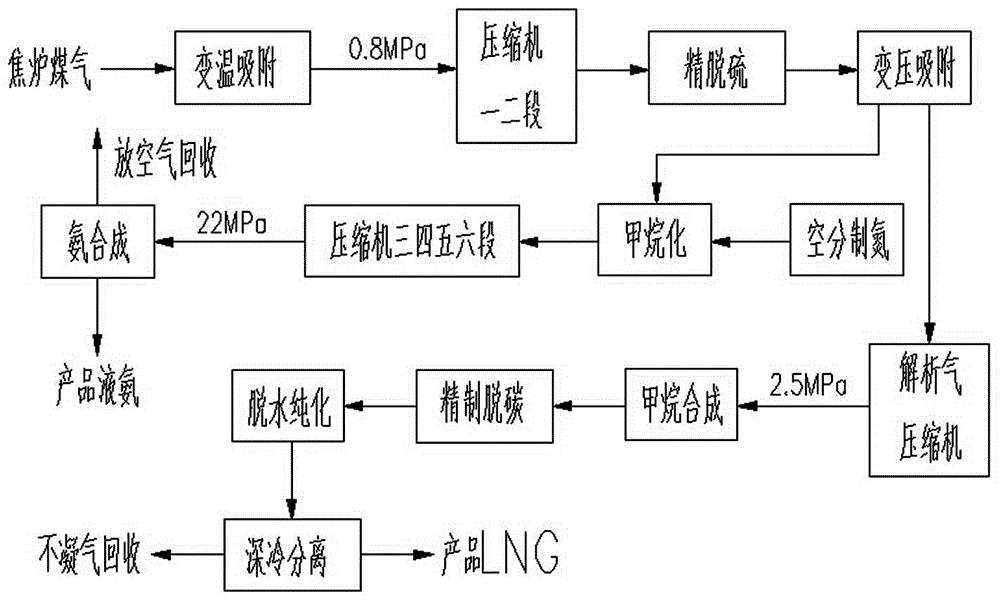

Coke oven coat gas comprehensive utilization method

InactiveCN105253899ATo achieve the purpose of comprehensive utilizationGas purification with selectively adsorptive solidsAmmonia preparation/separationMethanationHydrogen content

The present invention discloses a coke oven coat gas comprehensive utilization method, which comprises that: coke oven coal gas is subjected to temperature swing adsorption (TSA), fine desulfurization and pressure swing adsorption (PSA) to extract hydrogen so as to form two gases such as a high hydrogen content gas and a desorbing gas with a methane content of 50%; nitrogen gas is supplemented for the high hydrogen content gas, and methanation purification and deammoniation synthesis are performed to generate a product liquid ammonia under conditions such as catalysis, high temperature and high pressure; and the desorbing gas is conveyed into a methane liquefaction system and is compressed to achieve 2.5 MPa, and then methane synthesis, decarbonization, dehydration purification, and cryogenic separation are performed so as to finally form the liquefied methane (LNG) product. With the scheme of the present invention, the coke oven coal gas can be subjected to comprehensive utilization to obtain the two products.

Owner:BAOJI TAIHE CHEM TECH CO LTD

Liquid waste and exhaust gas recycling system for chemical by-products

InactiveCN102997251AReduce pollutionRealize energy savingStorage heatersIncinerator apparatusLiquid wasteCombustor

The invention relates to a liquid waste and exhaust gas recycling system for chemical by-products. The system comprises an incinerator, a waste heat boiler and a smoke system. The smoke outlet of the incinerator is connected with the waste heat boiler, the smoke outlet of the waste heat boiler is connected with the smoke system for processing waste heat smoke, a combustor is installed at the top of an air inlet tank of the incinerator, the combustor is connected with a natural gas system, an exhaust gas system is connected to the side wall of the air inlet tank, and a liquid waste groove is connected to the front end of a hearth of the incinerator. By recycling liquid waste and exhaust gas of chemical by-products, the environmental pollution is reduced, and heat is used to warm and heat by means of the arranged steam or conduction oil waste heat boiler, so that the purposes of energy conservation, environmental protection and comprehensive utilization of energy are realized.

Owner:CHANGZHOU OLYMSPAN THERMAL ENERGY EQUIP

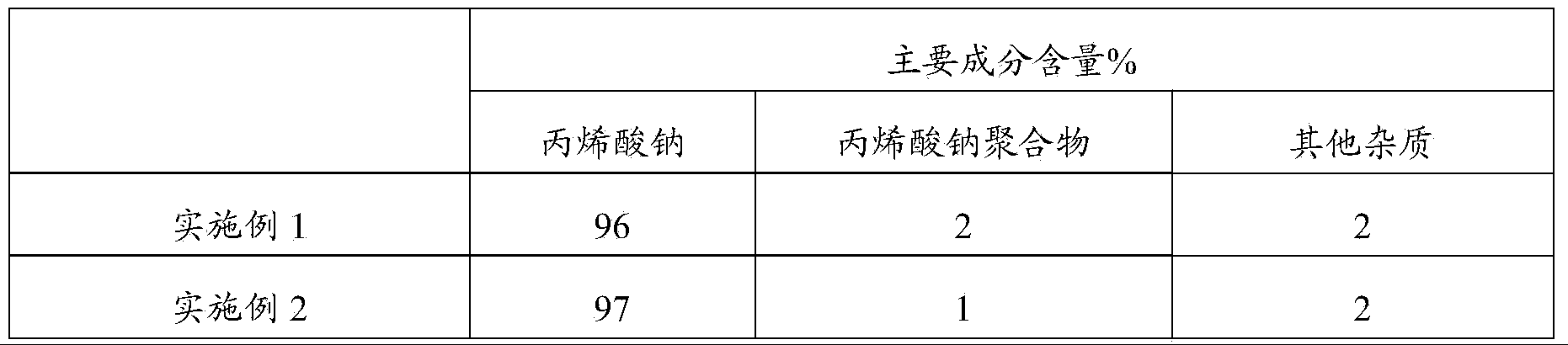

Treatment method of acrolein production residual liquid

ActiveCN103435470ALow costInhibit aggregationCarboxylic acid salt preparationSodium AcrylateSide reaction

Owner:重庆紫光合盛建材有限公司

Preparation method of ceramide

PendingCN108947864AImprove solubilityEasy to separateCarboxylic acid amide separation/purificationOrganic solventFree form

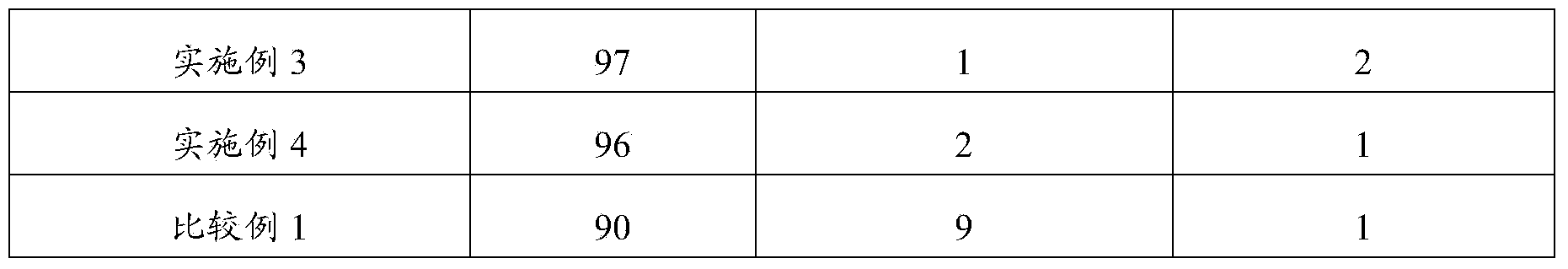

The invention discloses a preparation method of ceramide. The preparation method comprises the following steps: step 1, adding ethanol into konjac flying powder, carrying out stirring and filtering toobtain an ethanol extracting solution and a filter residue for later use; step 2, concentrating the ethanol extracting solution to obtain a concentrated paste; step 3, adding potassium hydroxide intothe concentrated paste, carrying out stirring to obtain a stirred liquid, adding petroleum ether into the stirred liquid, and carrying out extracting and concentrating to obtain a crude ceramide product; and step 4, adding an organic solvent into the crude ceramide product for dissolution, carrying out eluting by adopting an eluting agent to obtain an eluent, and carrying out drying to obtain theceramide. According to the preparation method, soaking is carried out by using the ethanol for removing peculiar-smell substances in the konjac flying powder, solid-liquid separation is carried out by adopting filtration, then an obtained solid is dried and used as feed, and an obtained liquid is used for preparing ceramide. Acidic substances such as fatty acids and the like in the crude ceramideproduct is neutralized through the addition of potassium hydroxide, so that the ceramide is promoted to exist in a free form, the purity of the prepared ceramide can reach 96% or above, and the use amount of organic reagents is low.

Owner:三原利华生物技术有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com