Comprehensive treatment method of dyeing wastewater

A technology for comprehensive treatment, printing and dyeing wastewater, applied in energy wastewater treatment, textile industry wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems of large area, low sludge yield, slow anaerobic reaction, etc. To achieve the effect of small footprint, good water quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

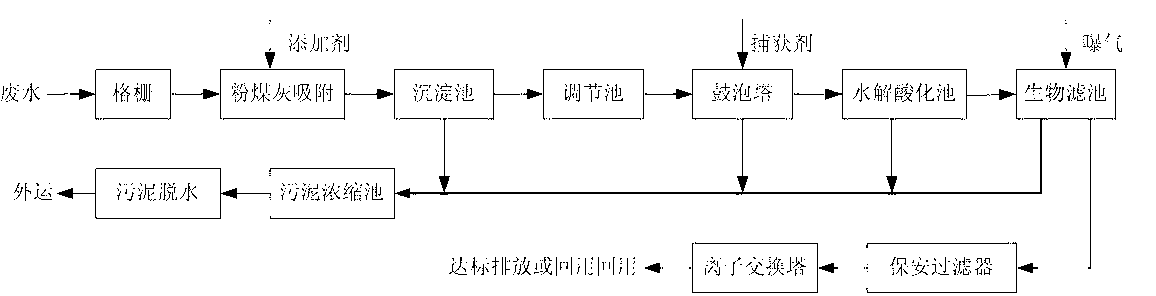

[0039] refer to figure 1 , a method for comprehensive treatment of printing and dyeing wastewater, comprising the following steps:

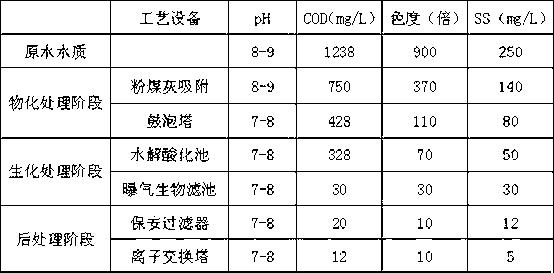

[0040] (1) After the waste water is intercepted by the grid, the adsorption treatment of fly ash is carried out. The particle size of the fly ash is 180 mesh, and the dosage of the fly ash is 8g / L; a certain amount of magnesium sulfate is put into the adsorption process, and the magnesium sulfate is added The amount is 0.15g / L; After this step, the removal rate of COD is 40.06%, the removal rate of SS is 48%, and the removal rate of chroma is 60%;

[0041] (2) Step (1) After the effluent is filtered by the sedimentation tank, it enters the adjustment tank to adjust the pH value to 8;

[0042] (3) The effluent from step (2) enters the bubble column and adds dodecyltrimethylammonium bromide as a capture agent for air flotation and decolorization treatment. The amount of dodecyltrimethylammonium bromide added and the adjustment The molar ratio of ...

Embodiment 2

[0051] refer to figure 1 , a method for comprehensive treatment of printing and dyeing wastewater, comprising the following steps:

[0052] (1) After the waste water is intercepted by the grid, the adsorption treatment of fly ash is carried out. The particle size of the fly ash is 200 mesh, and the dosage of the fly ash is 10g / L; a certain amount of magnesium sulfate is put into the adsorption process, and the magnesium sulfate is added The amount is 0.2g / L;

[0053] (2) Step (1) After the effluent is filtered by the sedimentation tank, it enters the adjustment tank to adjust the pH value to 7;

[0054] (3) The effluent of step (2) enters the bubble column and adds dodecyltrimethylammonium bromide as a capture agent for air flotation and decolorization treatment. The addition amount of dodecyltrimethylammonium bromide and adjustment The molar ratio of the amount of dye pigment detected in the pool is 0.9:1;

[0055] (4) The effluent from step (3) enters the hydrolytic acidi...

Embodiment 3

[0064] refer to figure 1 , a method for comprehensive treatment of printing and dyeing wastewater, comprising the following steps:

[0065] (1) After the waste water is intercepted by the grid, the adsorption treatment of fly ash is carried out. The particle size of the fly ash is 160 mesh, and the dosage of the fly ash is 10g / L; a certain amount of magnesium sulfate is put into the adsorption process, and the magnesium sulfate is added The amount is 0.15g / L;

[0066] (2) Step (1) After the effluent is filtered by the sedimentation tank, it enters the adjustment tank to adjust the pH value to 9;

[0067] (3) The effluent of step (2) enters the bubble column and adds dodecyltrimethylammonium bromide as a capture agent for air flotation and decolorization treatment. The addition amount of dodecyltrimethylammonium bromide and adjustment The molar ratio of the amount of dye pigment detected in the pool is 0.6:1;

[0068] (4) The effluent from step (3) enters the hydrolytic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com