Processing system for processing hemp into hemp fiber

A processing system and technology for hemp fibers, which are applied in the fields of fiber processing, fiber mechanical impurity removal, and chemical post-processing of fibers, etc., can solve the problems of long processing procedures of hemp fibers, difficulty in making high-end products, and backward production equipment, etc. The effect of centralized processing, stable heating temperature, reduction of difficulty and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

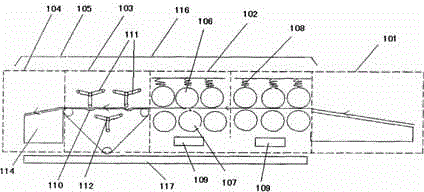

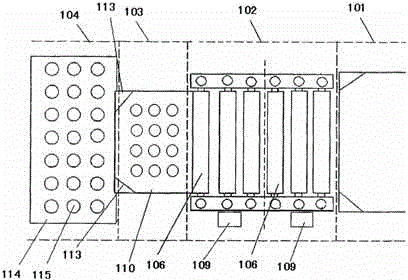

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

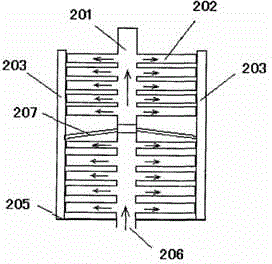

[0037] The basic technological process of hemp fiber processing is to unpack and sort the hemp husks, cut off the roots and slightly, and perform mechanical degumming on the mechanical degumming equipment; after mechanical degumming, the hemp is packed in cages, and then biological and / or high-temperature cooking degumming, high-temperature After rinsing, fiber-dividing, washing, rinsing, softening, and radio frequency drying, it is made into dry hemp. After being soft and healthy by machinery, the dry hemp is made into long hemp fiber strips by drawing, combing, combing, and drawing; for combed noil, Carry out carding and grading to make short hemp fibers.

[0038] Among the above-mentioned process routes, there are more equipments for mechanical degumming, biological degumming, high-temperature cooking, high-temperature rinsing, fiber separation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com