Method for performing anaerobic innocent treatment on erythromycin mushroom residue and using erythromycin mushroom residue for producing organic fertilizer

A technology for harmless treatment of erythromycin slag, applied in applications, fertilization devices, fertilizer mixtures, etc., can solve problems such as non-harmless treatment, complicated process, and difficult discharge, and achieve significant economic and social benefits , high processing efficiency and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The effective volume is 0.6m 3 In the reactor, 1 volume of erythromycin slag stock solution (water content 87%, wherein erythromycin residue is 316mg / L, organic matter content is about 58.6 g / L on average, mixed with 12 volumes of erythromycin production wastewater, Make the concentration of fungus residue 10 kg / m 3 , and then carry out continuous anaerobic reaction. During the anaerobic reaction, the pH value in the reaction system is 7.0, the reaction temperature is 28°C, and the residence time is 72h. After dehydration and drying, the moisture content was 16.1%, and the organic matter content was 45.1% on a dry basis, the pH value of the 10% aqueous solution was 7.1, and the residual erythromycin was 5.4 mg / kg. Take 119g of dehydrated and dried sediment (100g on a dry basis), then add 30g of humic acid (60% humus, 30% moisture), 20g bentonite (23% moisture content), mix and stir, granulate, and then dry to prepare Get organic fertilizer, the composition of gained o...

Embodiment 2

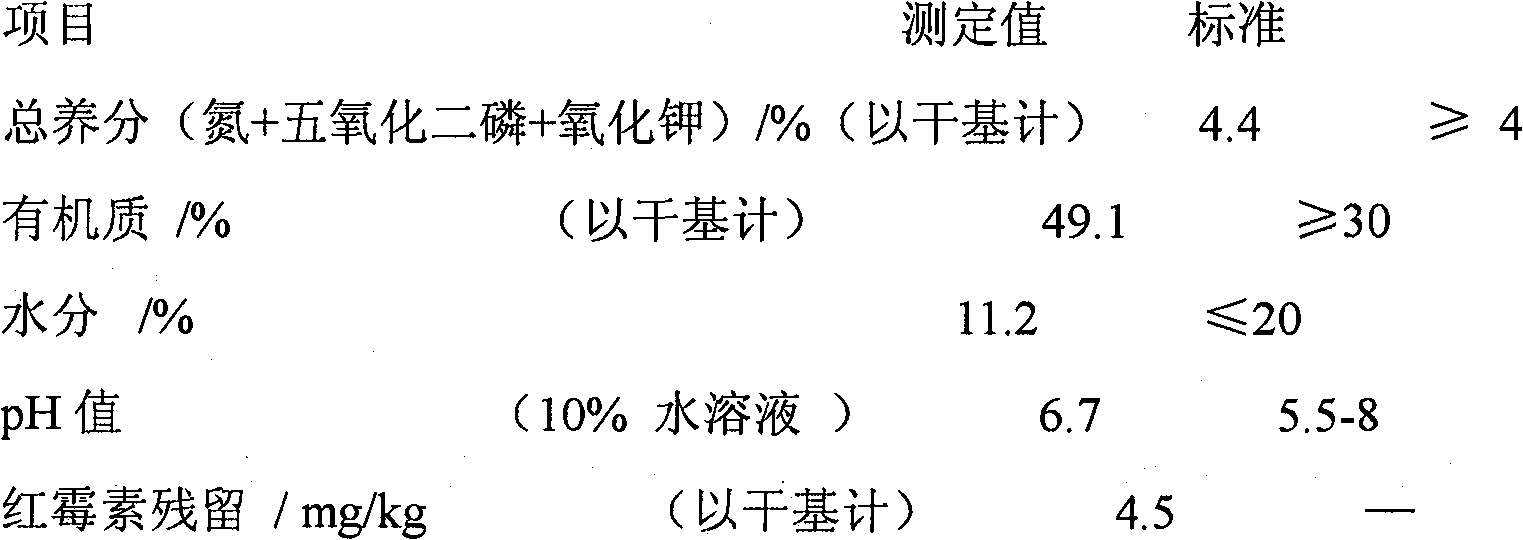

[0028] The effective volume is 0.6m 3 In the reactor, 1 volume of erythromycin slag stock solution (water content 87%, wherein erythromycin residue is 316mg / L, organic matter content is about 58 g / L on average, mixed with 5.5 volumes of erythromycin production wastewater, Make the concentration of fungus residue 20 kg / m 3 , and then carry out continuous anaerobic reaction. During the anaerobic reaction, the pH value in the reaction system is 6.5, the reaction temperature is 68°C, and the residence time is 36h. After the thing is dehydrated and dried, the moisture content is 15.5%. On a dry basis, the organic matter content is 45.8%. The pH value of the 10% aqueous solution is 6.8, and the residue of erythromycin is 6.1 mg / kg. After dehydration and drying, 118g of the precipitate (dried Basis weight 100g), then add humic acid (60% humus, 30% moisture) 35g, bentonite 15g (moisture content 23%), mix and stir, granulate, and then dry to make organic fertilizer, the composition of...

Embodiment 3

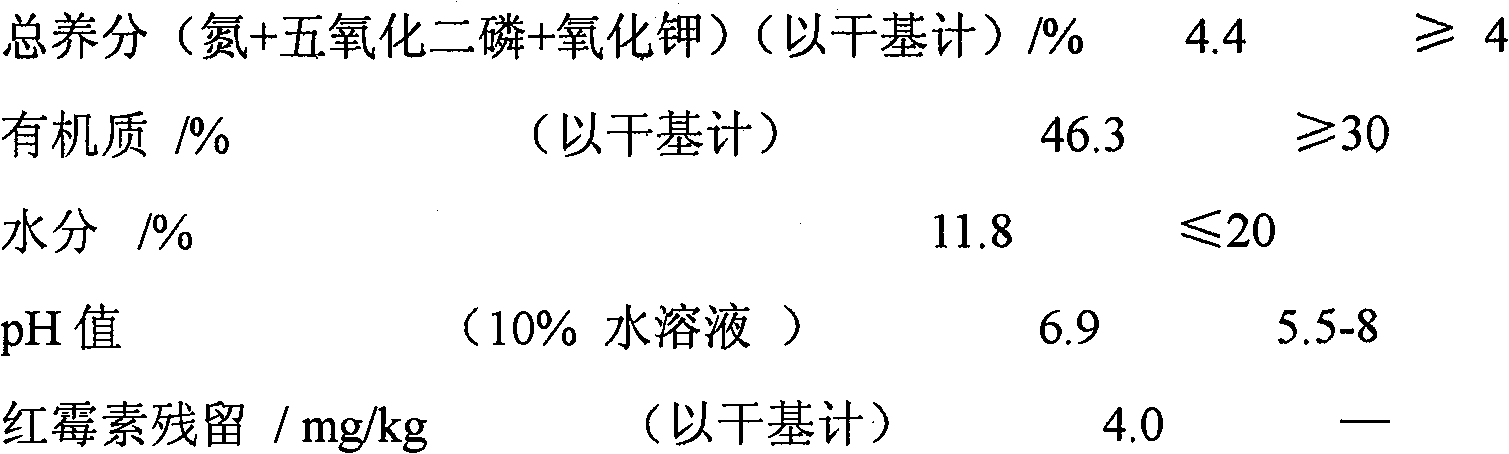

[0031] The effective volume is 0.6m 3 In the reactor, 1 volume of erythromycin slag stock solution (moisture content 87%, wherein erythromycin residue is 316mg / L, organic matter content is about 58 g / L on average, mixed with 8.67 volumes of erythromycin production wastewater, Make the concentration of fungus residue 15 kg / m 3, and then carry out continuous anaerobic reaction. During the anaerobic reaction, the pH value in the reaction system is 8.0, the reaction temperature is 55°C, and the residence time is 50h. After dehydration and drying, the moisture content was 17.2%, and the organic matter content was 44.5% on a dry basis, the pH value of the 10% aqueous solution was 7.8, and the residual erythromycin was 3.6 mg / kg. Take 120g of dehydrated and dried sediment (100g on a dry basis), then add 40g of humic acid (60% humus, 30% moisture), 10g bentonite (23% moisture content), mix and stir, granulate, and dry to prepare Get organic fertilizer, the composition of gained orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com