Comprehensive utilization method of granite

A granite and mineral technology, applied in the field of comprehensive utilization of granite, can solve the problems of high cost of chemicals, high pressure on environmental protection, low content, etc., and achieve the effects of avoiding mechanical pollution, less mechanical pollution, and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail in conjunction with specific embodiments.

[0031] The invention provides a comprehensive utilization method of granite.

[0032] In the specific implementation process of this method, the steps are as follows:

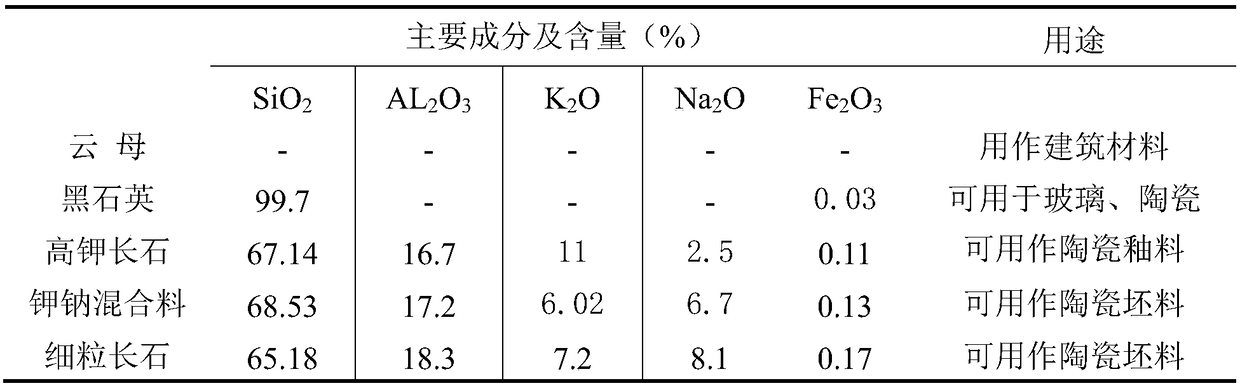

[0033] 1. Crushing-sand making: Granite is roughly crushed by the jaw crusher, screened by the linear vibrating screen, the product on the screen returns to coarse crushing, and the product under the screen (-3cm) enters the cone crusher for fine crushing, and then screened by the linear vibrating screen again , the product on the sieve returns to fine crushing, and the fine ore under the sieve (-1.3cm) enters the vertical impact crusher and is screened by a linear vibrating screen to obtain granite particles of 1-4mm and under-sieve material of -1mm . Particles of 1-4mm enter the dry magnetic separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com