Comprehensive recovery method of waste CRT (Cathode Ray Tube) cone glass

A recycling method and cone glass technology, which is applied in the field of comprehensive recycling of waste CRT cone glass, can solve problems such as product hazards, inability to effectively extract lead, and large environmental pollution, and achieve the effect of comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

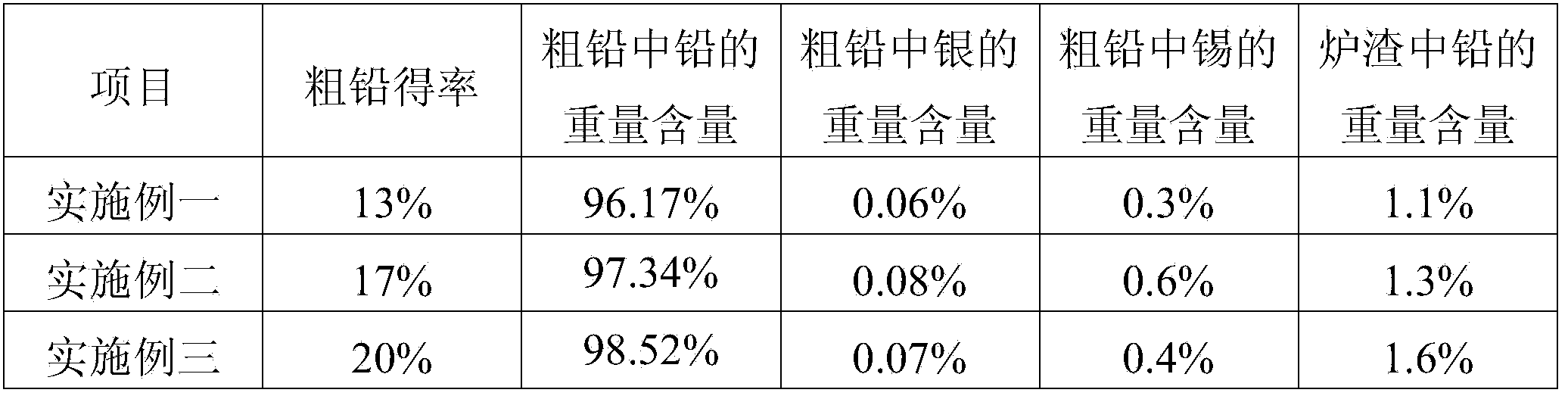

Embodiment 1

[0027] Weigh 20 tons of waste CRT cone glass with a particle size of 80mm, 60 tons of lead oxide ore in the form of 240mm×120mm×60mm block, and 20 tons of coke with a particle size of 100mm, and mix them to obtain the primary mixture; detect the primary mixture FeO, SiO 2 , CaO, MgO, Zn, S and Al 2 o 3 The weight content of FeO is 26%, SiO 2 The weight content is 25%, the weight content of CaO is 15%, the weight content of MgO is 16%, the weight content of Zn is 5%, the weight content of S is 1% and Al 2 o 3 The weight content is 5%. The primary mixture is smelted in a blast furnace at a temperature of 1200° C. and a smelting time of 6 hours. Lead liquid, slag and smoke are obtained respectively, and the lead liquid is cast into ingots to obtain crude lead products; the smoke and dust are settled, cooled, and bagged to collect dust to obtain standard flue gas; the slag and collected smoke can be recycled as raw materials for the rotary kiln. Among them, the weight content...

Embodiment 2

[0029] Weigh 15 tons of waste CRT cone glass with a particle size of 60mm, 50 tons of lead oxide ore, 20 tons of lead concentrate and 15 tons of coke with a particle size of 120mm, and mix them to obtain the initial mixture; detect the initial mixture FeO, SiO 2 , CaO, MgO, Zn, S and Al 2 o 3 The weight content of FeO is 32%, SiO 2 The weight content of is 20%, the weight content of CaO is 8%, the weight content of MgO is 17%, the weight content of Zn is 3%, the weight content of S is 0.6% and Al 2 o 3 The weight content is 4%. Add 7 tons of calcium stone containing CaO to the initial mixture and mix well to obtain a mixture. Detect, the weight content of FeO in this mixture is 30%, SiO 2 The weight content of is 21.4%, the weight content of CaO is 12%, the weight content of MgO is 17.6%, the weight content of Zn is 1.2%, the weight content of S is 0.57% and Al 2 o 3The weight content is 2.8%. Then put the mixture in a blast furnace for smelting, the smelting temperatu...

Embodiment 3

[0031] Weigh 25 tons of waste CRT cone glass with a particle size of 100mm, 20 tons of lead-acid battery plates, 30 tons of lead oxide ore and 25 tons of coke with a particle size of 80mm, and mix them to obtain the initial mixture; detect the initial mixture FeO, SiO 2 , CaO, MgO, Zn, S and Al 2 o 3 The weight content, the weight content of FeO is 28%, SiO 2 The weight content of CaO is 17%, the weight content of CaO is 7.5%, the weight content of MgO is 17%, the weight content of Zn is 4%, the weight content of S is 0.8% and Al 2 o 3 The weight content is 6%. Add 8 tons of calcium stone containing CaO and 8 tons containing SiO 2 Mix 10 tons of silica into the initial mixture to obtain a mixture. Detect, the weight content of FeO in this mixture is 26%, SiO 2 The weight content of is 22%, the weight content of CaO is 13.4%, the weight content of MgO is 16.3%, the weight content of Zn is 2.4%, the weight content of S is 0.61% and Al 2 o 3 The weight content is 3.2%. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com