Concrete taking green mud and white mud as admixtures and preparation method for concrete

A technology for concrete and admixtures, applied in the field of building materials, can solve the problems of pollution, low concrete production cost, land and environment occupied by pulp waste residues, etc., and achieves a simple production process, which is beneficial to environmental protection, energy saving and emission reduction, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First dealkalize the green mud and white mud and dry them until the water content is less than 3%, and set aside;

[0025] The composition of the cementitious material (percentage by weight on a dry basis): green mud and white mud 10, cement 45, basalt waste rock powder 30, fly ash 15;

[0026] Concrete mix composition per cubic meter: 270 kg of cementitious material, 850 kg of sand, 1050 kg of stone, 165 kg of water, and 3.78 kg of water reducing agent based on 1.4% of cementitious material.

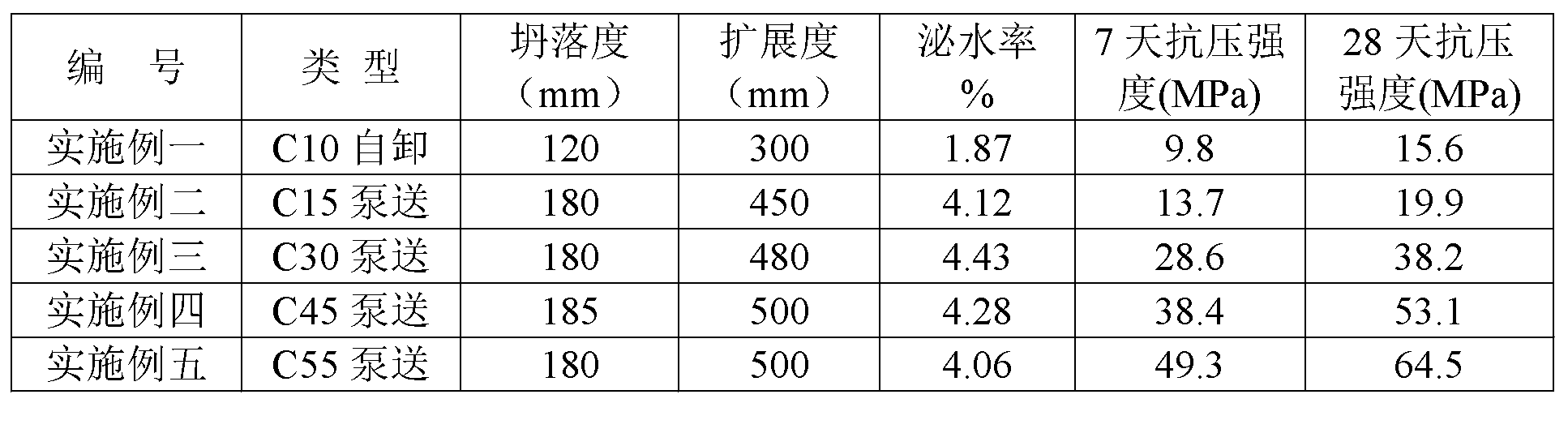

[0027] Add the above concrete mix ratio components into the mixer for forced mixing, and then the C10 concrete that meets the self-unloading requirements can be prepared. The specific properties are shown in Table 1.

Embodiment 2

[0029] First dealkalize the green mud and white mud and dry them until the water content is less than 3%, and set aside;

[0030] Composition of cementitious material (percentage by weight on a dry basis): 20% green mud and white mud, 45% cement, 35% basalt waste rock powder;

[0031] Concrete mix composition per cubic meter: 300 kg of cementitious material, 900 kg of sand, 930 kg of stone, 175 kg of water, and 5.1 kg of water reducer based on 1.7% of cementitious material.

[0032] Add the above concrete mix ratio components into the mixer for forced mixing, and the C15 concrete that meets the pumping requirements can be prepared. The specific properties are shown in Table 1.

Embodiment 3

[0034] First dealkalize the green mud and white mud and dry them until the water content is less than 3%, and set aside;

[0035] Composition of cementitious materials (percentage by weight on a dry basis): green mud and white mud 10, cement 55, basalt waste rock powder 10, blast furnace slag powder 15, fly ash 10;

[0036] Concrete mix composition per cubic meter: 360 kg of cementitious material, 850 kg of sand, 980 kg of stone, 170 kg of water, and 7.2 kg of water reducing agent based on 2.0% of cementitious material.

[0037] Add the above concrete mix ratio components into the mixer for forced mixing, and the C30 concrete that meets the pumping requirements can be prepared. The specific properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com