Production method of sylvinite

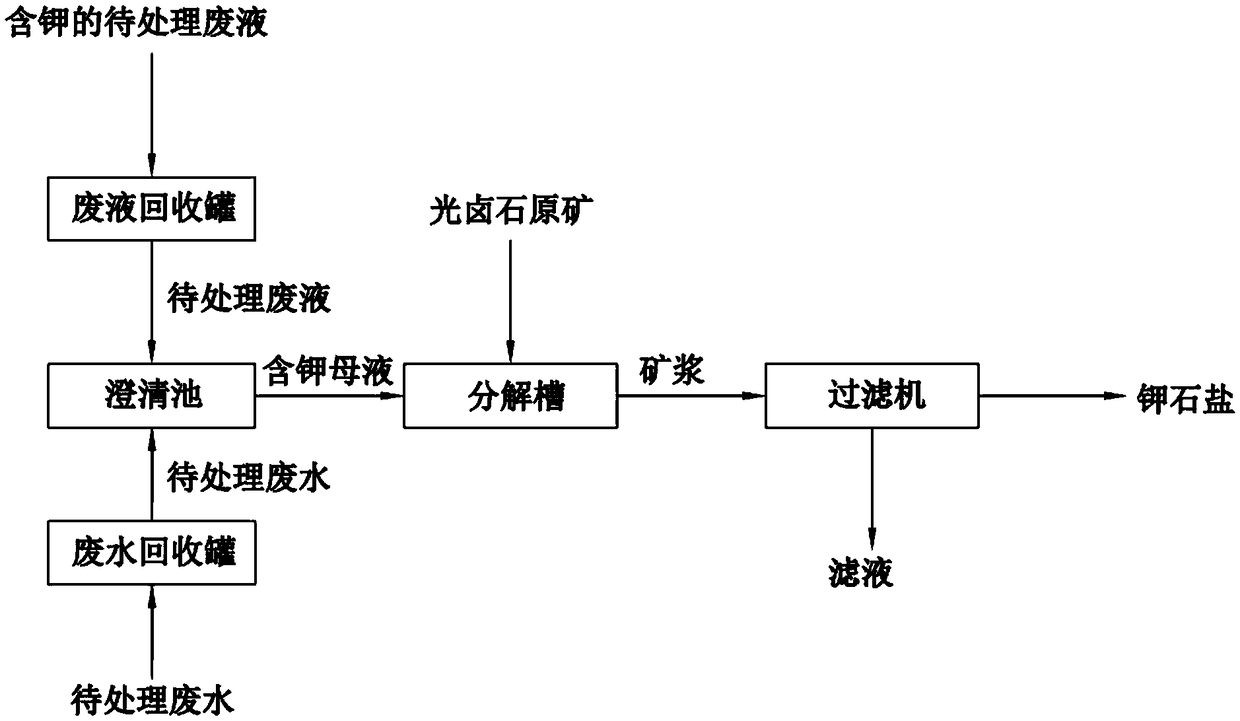

A production method, the technology of potassium halite, applied in the direction of alkali metal chloride, etc., can solve the problems of difficult control of water and mineral ratio, waste of water resources, large equipment loss, etc., to reduce equipment load, control, energy saving and emission reduction , The effect of reducing energy consumption and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

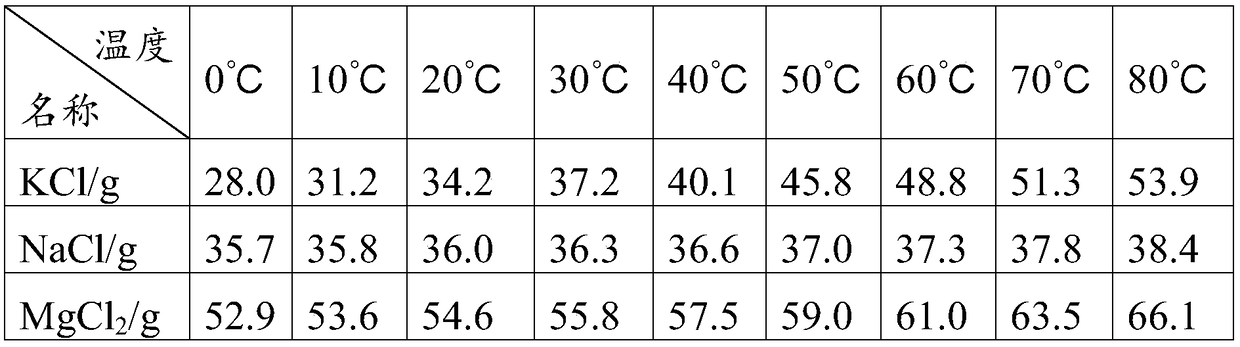

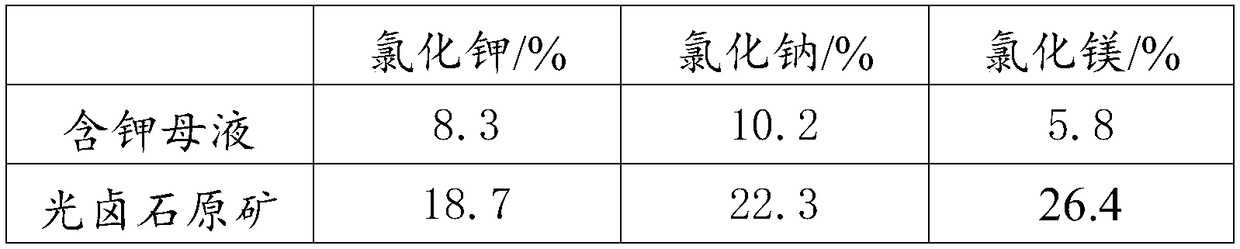

[0053] Collect the waste liquid to be treated containing potassium to the waste liquid recovery tank, the waste liquid to be treated includes the solid-liquid mixture discharged from the underflow of the thickener in the thermal solution system; the waste water to be treated is collected to the waste water recovery tank, and the waste water to be treated includes cooling water; the waste liquid to be treated and the waste water to be treated are proportioned in a clarifier to obtain a potassium-containing mother liquor; 159.6 tons of the potassium-containing mother liquor are dissolved in a decomposition tank to dissolve 100 tons of carnallite ore to obtain ore pulp, The dissolution temperature is 10°C, and the dissolution time is 22 minutes; the pulp is filtered through a filter to obtain 63.48 tons of potassium halite and filtrate, which are transported to the salt field for drying.

[0054] In this embodiment, the mass fractions of each component of the potassium-containing ...

Embodiment 2

[0058] Collect the potassium-containing waste liquid to be treated to the waste liquid recovery tank, the waste liquid to be treated includes the magnesium discharge mother liquor of the crystallization system; the waste water to be treated is collected to the waste water recovery tank, and the waste water to be treated includes equipment flushing water; The waste liquid to be treated and the waste water to be treated are proportioned in a clarifier to obtain a potassium-containing mother liquor; 135 tons of the potassium-containing mother liquor are dissolved in a decomposition tank with 100 tons of carnallite raw ore to obtain a pulp with a dissolution temperature of 8°C. The dissolution time is 27 minutes; the pulp is filtered through a filter to obtain 80 tons of potassium halite and filtrate, which is transported to the salt field for drying.

[0059] In this embodiment, the mass fractions of each component of the potassium-containing mother liquor, the carnallite ore, the...

Embodiment 3

[0063] Collect the potassium-containing waste liquid to be treated to the waste liquid recovery tank, the waste liquid to be treated includes the magnesium discharge mother liquor of the crystallization system; the waste water to be treated is collected to the waste water recovery tank, and the waste water to be treated includes equipment flushing water; The waste liquid to be treated and the waste water to be treated are proportioned in a clarifier to obtain a potassium-containing mother liquor; 110 tons of the potassium-containing mother liquor are dissolved in a decomposition tank with 100 tons of carnallite raw ore to obtain ore pulp, and the dissolution temperature is 12 ° C. The dissolution time is 17 minutes; the pulp is filtered through a filter to obtain 47.19 tons of potassium halite and filtrate, which are transported to the salt field for drying.

[0064] In this embodiment, the mass fractions of each component of the potassium-containing mother liquor, the carnalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com