Method for treating waste compound salt by-products and waste washing water of tantalum powder production by sodium reduction method

A technology of compound salt and reduction method, which is applied in the field of metallurgy, can solve the problems such as the difficulty of wastewater discharge to meet the standard, the large amount of washing water, and the large amount of lime used, and achieve the effect of reducing the amount of washing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

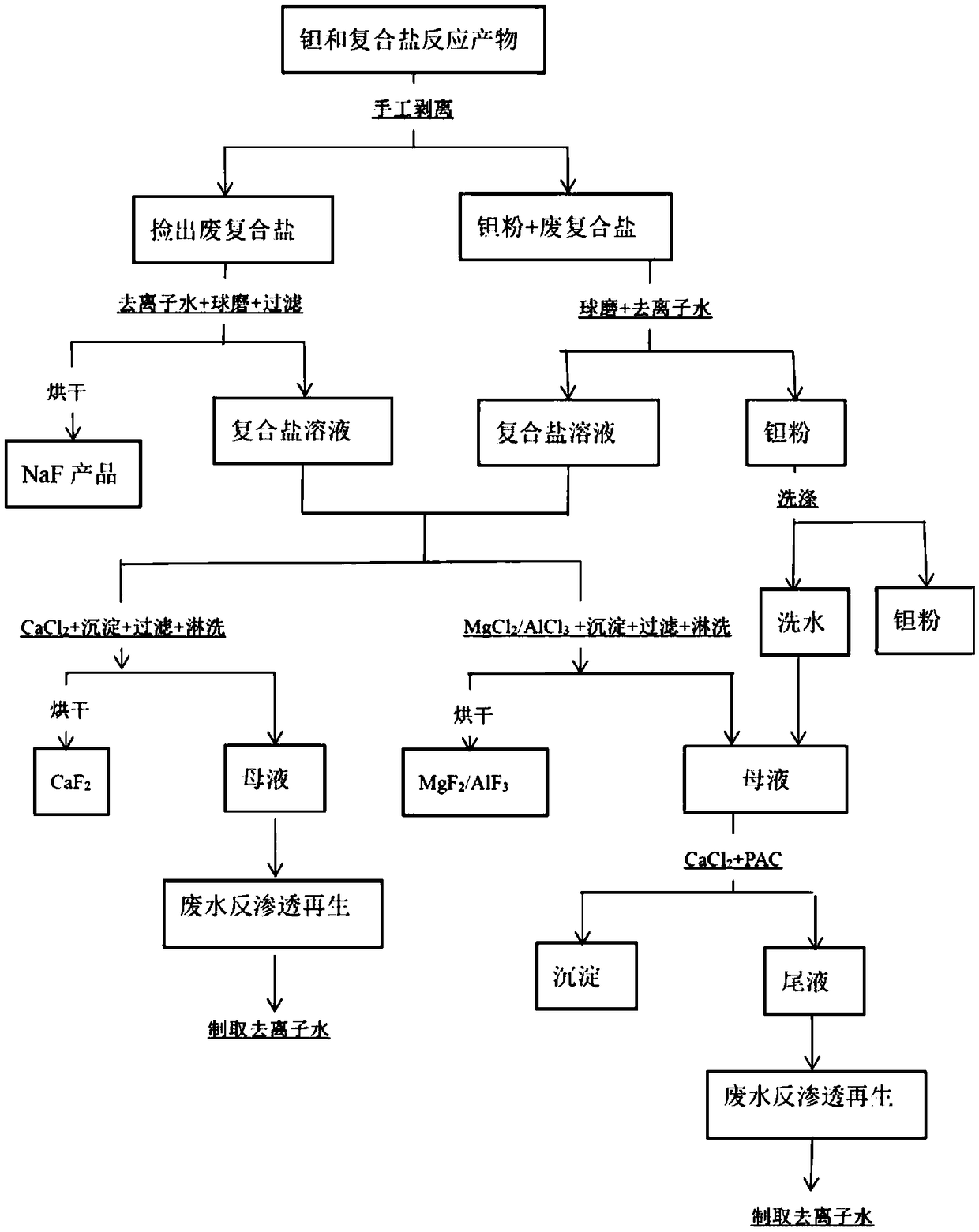

[0040] This embodiment is specifically a method for treating waste composite salt by-products and waste washing water of tantalum powder produced by a sodium reduction method. The experimental raw materials in this example are: 200kg K 2 TaF 7 Carry out sodium reduction reaction with 60kgNa and 75kgNaCl, obtain reaction product tantalum and composite salt, this product is solid after cooling, gross weight 335kg, as figure 1 As shown, part of the complex salt floated on top of the reaction product. like figure 2 As shown, a simplified process flow diagram of a method for treating waste composite salt by-products of tantalum powder and waste washing water by a sodium reduction method of the present embodiment, the specific operations of the present embodiment are as follows:

[0041] S1. Peeling: Pick out the upper layer by manual peeling, and weigh 68kg of the picked-up waste compound salt. The picked-up product is detected to contain NaCl 31.1%, KF 24.5%, and NaF 44.4%;

...

Embodiment 2

[0048] The present embodiment is specifically a method for treating waste composite salt by-products and waste washing water of tantalum powder produced by a sodium reduction method, such as figure 2 As shown, a simplified process flow diagram of a method for treating waste composite salt by-products and waste washing water of tantalum powder produced by a sodium reduction method in this embodiment.

[0049] This embodiment uses raw materials, and steps S1 to S4 are the same as those in Embodiment 1, and other specific steps are as follows:

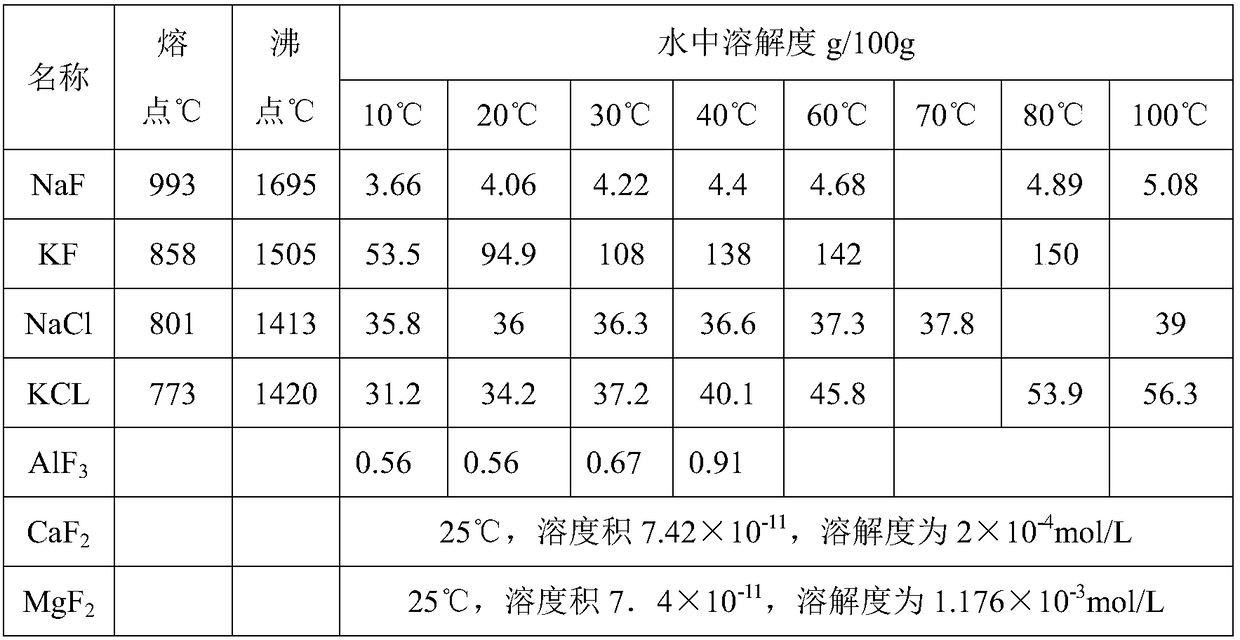

[0050] S5. metal calcium salt precipitation: after the combined solution of step S4 is fully stirred and merged, take 920ml of a nearly saturated solution with a NaF content of 37.83g / L, add 94.724g calcium chloride (containing 6 crystal water), precipitate, filter, rinse, After drying, 31.14g CaF was obtained 2 product, the recovery rate of F ions is as high as 96.35%; 2 The mother liquor contains 1.51mg / L of F ions, which is lower th...

Embodiment 3

[0053] The present embodiment is specifically a method for treating waste composite salt by-products and waste washing water of tantalum powder produced by a sodium reduction method, such as figure 2 As shown, a simplified process flow diagram of a method for treating waste composite salt by-products and waste washing water of tantalum powder produced by a sodium reduction method in this embodiment.

[0054] The raw materials, steps S1 to S4 of this embodiment are the same as those of Embodiment 1, and other specific steps are as follows:

[0055] S5. metal magnesium salt precipitation: after the combined solution of step S4 is fully stirred and combined, take 920ml of a nearly saturated solution with a NaF content of 37.83g / L, add 29g of MgCl 2 , precipitation, filtration, washing, drying to obtain 23.68gMgF 2 product, F ion recovery was 96.40%, precipitation MgF 2 The mother liquor contains 32.3mg / L of fluoride ions;

[0056] S6. Mother liquor purification: add an approp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com