Method for preparing sodium sulfide by smelting reduction of industrial sodium sulfate

A technology of sodium sulfate and sodium sulfide, applied in the direction of alkali metal sulfide/polysulfide, etc., can solve the problems of low purity of sodium sulfide, large environmental pollution, complicated process, etc., and achieve improved reduction efficiency, low environmental pollution, and high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The method for preparing sodium sulfide of the present invention has the following advantages compared with traditional methods:

[0046] (1) The intermediate frequency induction blowing furnace is used as the reduction equipment, which saves energy and has high production efficiency;

[0047] (2) Use nitrogen to carry out dynamic stirring, reduce the consumption of reducing gas, make reducing gas and molten state sodium sulfate contact more fully simultaneously, improve reducing efficiency;

[0048] (3) It is an all-fire process, does not need to use water immersion process, and has less corrosion to equipment;

[0049] (4) the method is simple and feasible to operate, and can prepare high-purity sodium sulfide whose content is more than 90% by weight;

[0050] (5) Compared with the wet process, the environmental impact is small, and it mainly produces waste gas that can be absorbed, and does not produce waste water and waste residue.

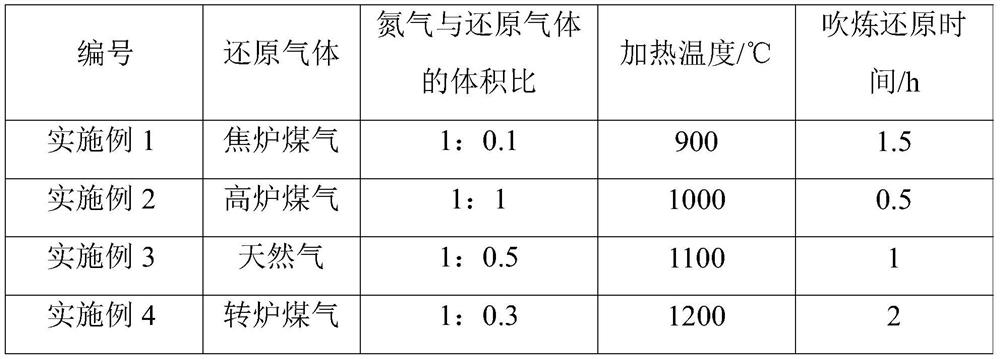

Embodiment 1-4

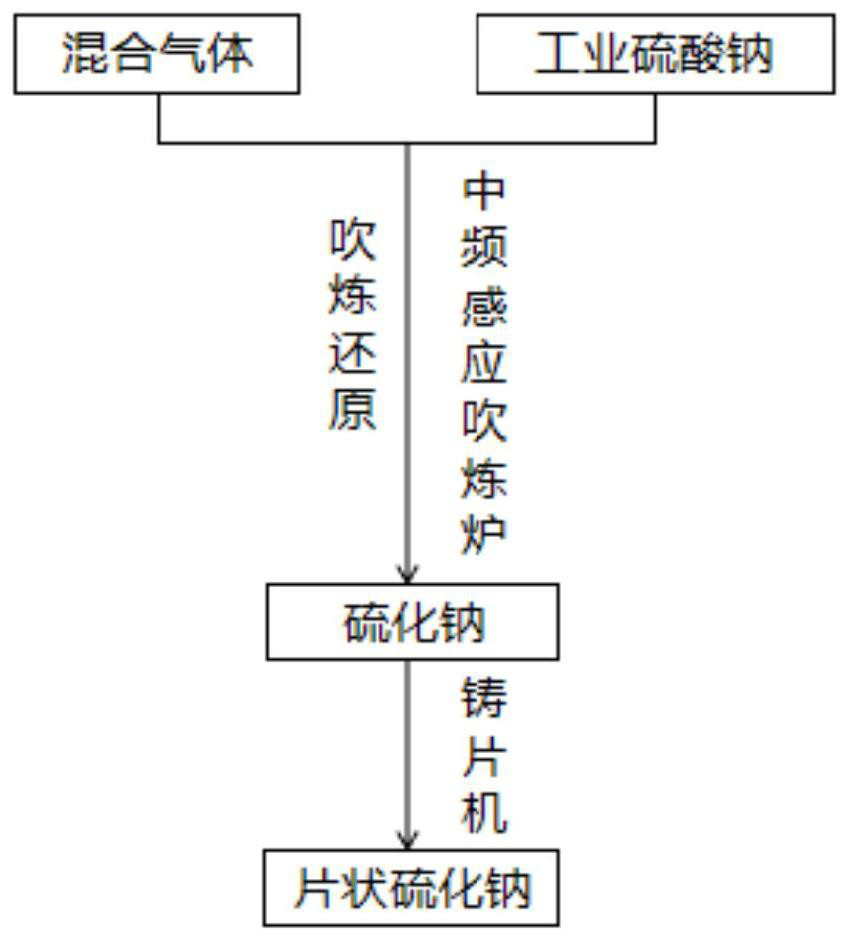

[0053] (1) Add industrial sodium sulfate (industrial sodium sulfate is a by-product of sodium vanadium extraction process) to an intermediate frequency induction blowing furnace for heating, and heat it to a molten state; then inject nitrogen and reducing gas into the molten sodium sulfate The mixed gas is carried out blowing reduction, the molten sodium sulfate is reduced to molten sodium sulfide, and then the molten sodium sulfide is poured out from the intermediate frequency induction blowing furnace;

[0054] (2) the molten sodium sulfide poured out in the step (1) is cast;

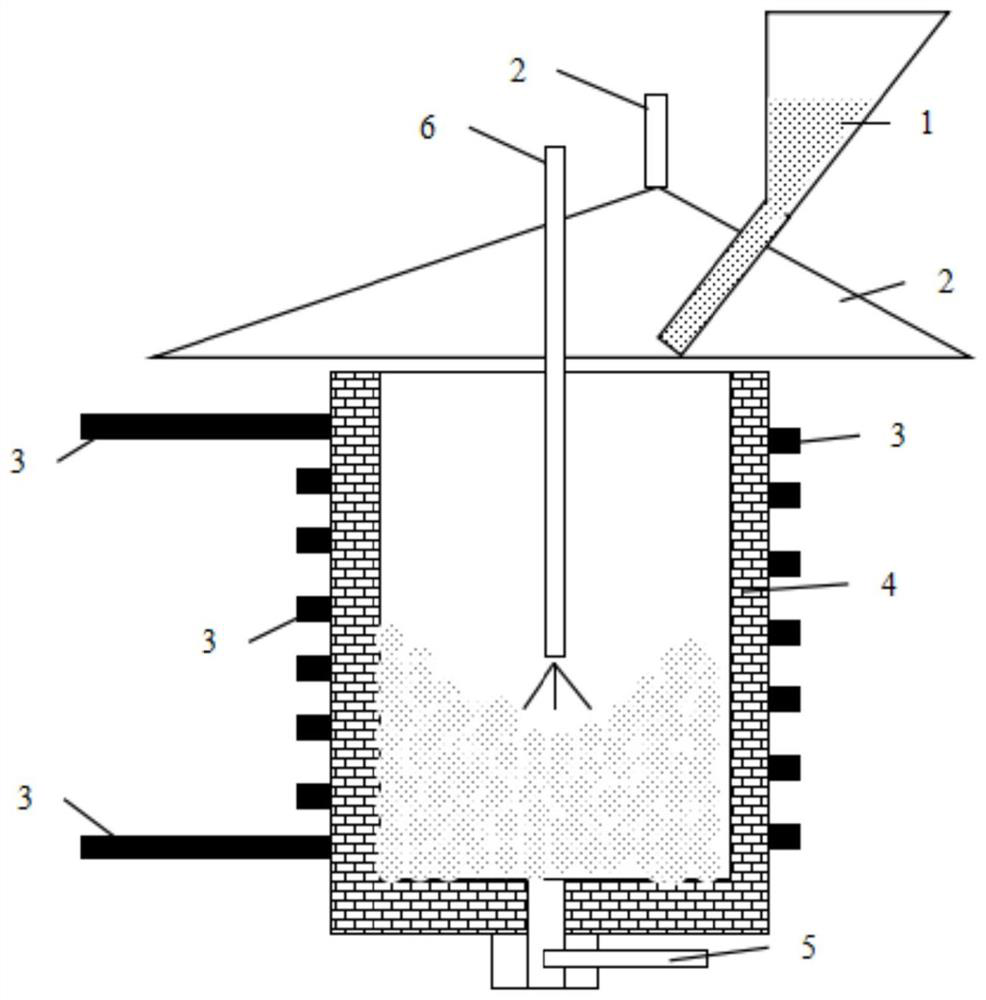

[0055] In step (1), specifically, the schematic diagram of the cross-sectional structure of the intermediate frequency induction converting furnace is as follows figure 2 As shown, the intermediate frequency induction converting furnace includes a feeding device 1, a dust collection device 2, an induction coil 3, a heating body 4, a sliding nozzle 5 and a converting gun 6; the heating body 4 is a cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com