Preparation method of catalyst containing small-grain Y-type molecular sieve

A molecular sieve, small-grain technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor thermal and hydrothermal stability, difficult elution of fluoride ions, and small batch size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

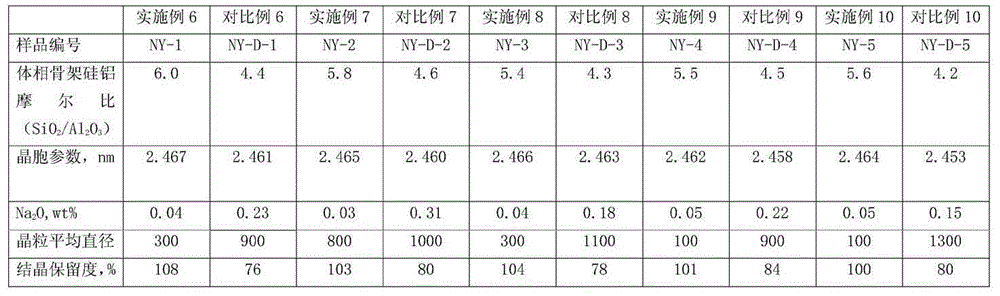

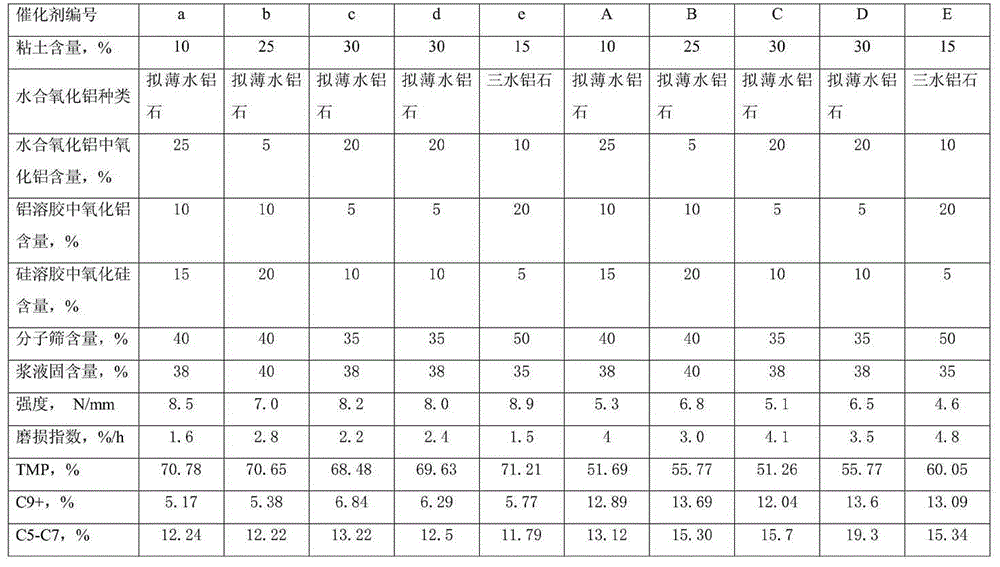

Examples

Embodiment 1

[0037] This example illustrates the synthesis process of NaY molecular sieves.

[0038] 50.39g high alkali sodium metaaluminate solution (provided by Sinopec Catalyst Changling Branch, Al 2 o 3 The content is 40.2g / L, Na 2 O content is 255g / L, specific gravity is 1.324) joins 65.56g water glass (Sinopec Catalyst Changling Branch provides, SiO 2 The content is 260.6g / L, Na 2 The O content is 81.6g / L, the specific gravity is 1.2655, and the modulus is 3.3), aged with stirring at room temperature for 48 hours, then statically aged at 60°C for 5 hours, and finally added 15g of deionized water, the resulting directing agent has a final molar ratio of 15Na 2 O: A1 2 o 3 :15SiO2 2 :320H 2 O.

[0039] All the directing agents prepared were used in the preparation of the following reaction mixture, and the amount of the directing agent added was calculated according to the fact that the moles of aluminum in the directing agent accounted for 3% of the total moles of aluminum. ...

Embodiment 2

[0050] This example illustrates the synthesis process of NaY molecular sieves.

[0051] 50.39g high alkali sodium metaaluminate solution (provided by Sinopec Catalyst Changling Branch, Al 2 o 3 The content is 40.2g / L, Na 2 O content is 255g / L, specific gravity is 1.324) joins 65.56g water glass (Sinopec Catalyst Changling Branch provides, SiO 2 The content is 260.6g / L, Na 2 The O content is 81.6g / L, the specific gravity is 1.2655, and the modulus is 3.3), aged with stirring at 60°C for 5 hours, then statically aged at 60°C for 5 hours, and finally added 15g of Ionized water, the final molar ratio of the resulting directing agent is 15Na 2 O: A1 2 o 3 :15SiO2 2 :320H 2 O.

[0052] All the directing agents prepared were used in the preparation of the following reaction mixture, and the amount of the directing agent added was calculated according to the fact that the moles of aluminum in the directing agent accounted for 3% of the total moles of aluminum.

[0053] Under...

Embodiment 3

[0063] This example illustrates the synthesis process of NaY molecular sieves.

[0064] With 164.54g high alkali sodium metaaluminate solution (Sinopec Catalyst Changling Branch Company provides, Al 2 o 3 The content is 40.2g / L, Na 2 O content is 340g / L, specific gravity is 1.297) joins 291.37g water glass (Sinopec Catalyst Changling Branch provides, SiO 2 The content is 260.6g / L, Na 2 The O content is 81.6g / L, the specific gravity is 1.2655, and the modulus is 3.3), aged with stirring at 30°C for 20 hours, then statically aged at 40°C for 15 hours, and finally added 60g of ionized water. The resulting directing agent has a final molar ratio of 20Na 2 O: A1 2 o 3 :20SiO2 2 :380H 2 O.

[0065] All the directing agents prepared were used in the preparation of the following reaction mixture. The amount of the directing agent added was calculated according to the fact that the moles of aluminum in the directing agent accounted for 10% of the total moles of aluminum.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com