Method for preparing sodium sulfide by smelting reduction of industrial sodium sulfate

A technology of sodium sulfate and sodium sulfide, applied in the direction of alkali metal sulfides/polysulfides, etc., can solve the problems of equipment corrosion, large environmental pollution, complex process, etc., and achieve the effect of less equipment corrosion, less environmental pollution, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

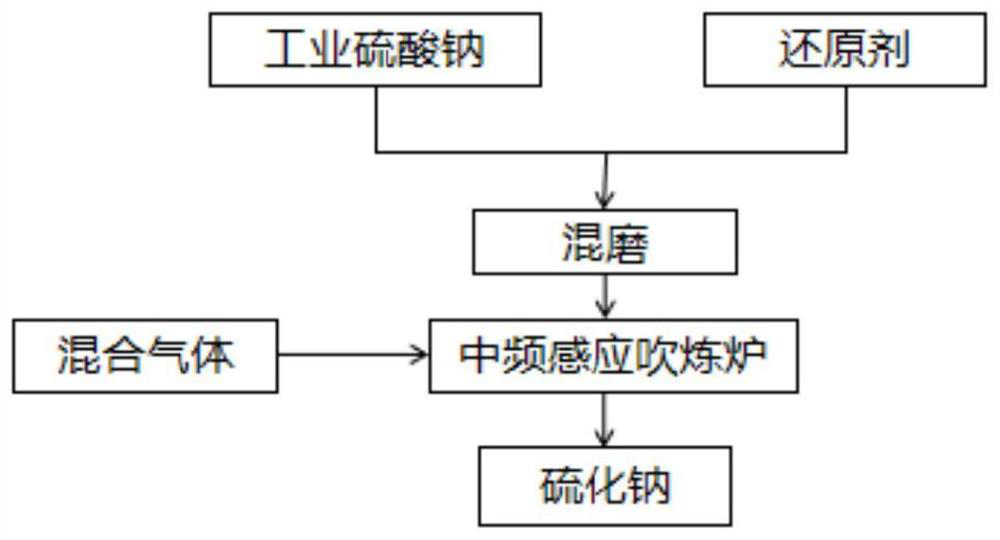

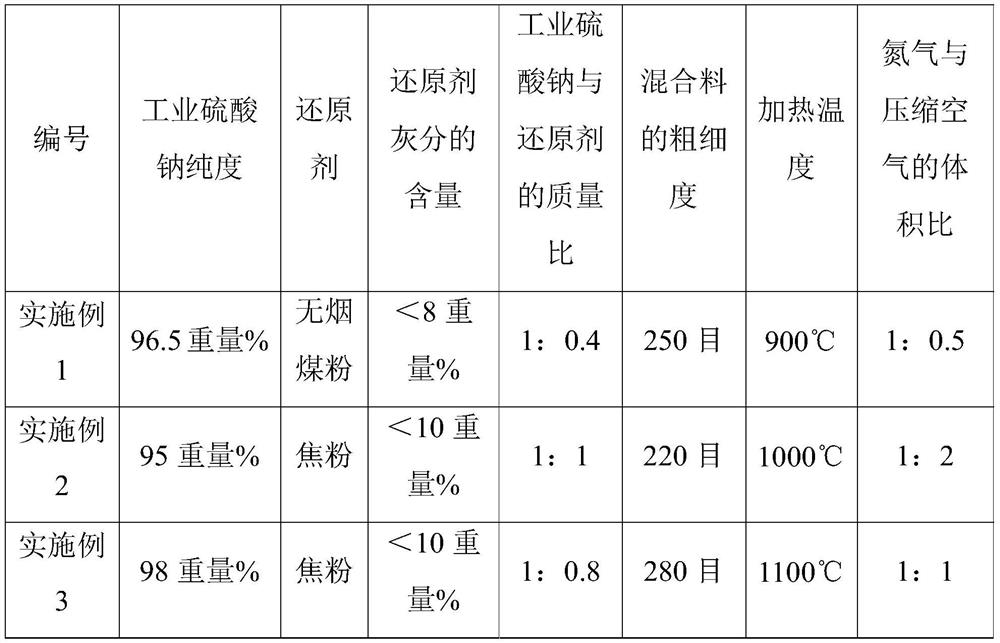

[0057] (1) ball milling after mixing industrial sodium sulfate (industrial sodium sulfate is the by-product of the process of extracting vanadium by sodiumization) and reducing agent, to obtain a mixture whose thickness is less than or equal to 200 mesh;

[0058] (2) Add the mixture obtained in step (1) to an intermediate frequency induction blowing furnace, heat it to a molten state, and then blow the mixed gas for blowing reduction, the molten sodium sulfate is reduced to molten sodium sulfide, and then the molten Sodium sulfide is poured out from the intermediate frequency induction converting furnace;

[0059] (3) the molten sodium sulfide poured out in the step (2) is cast;

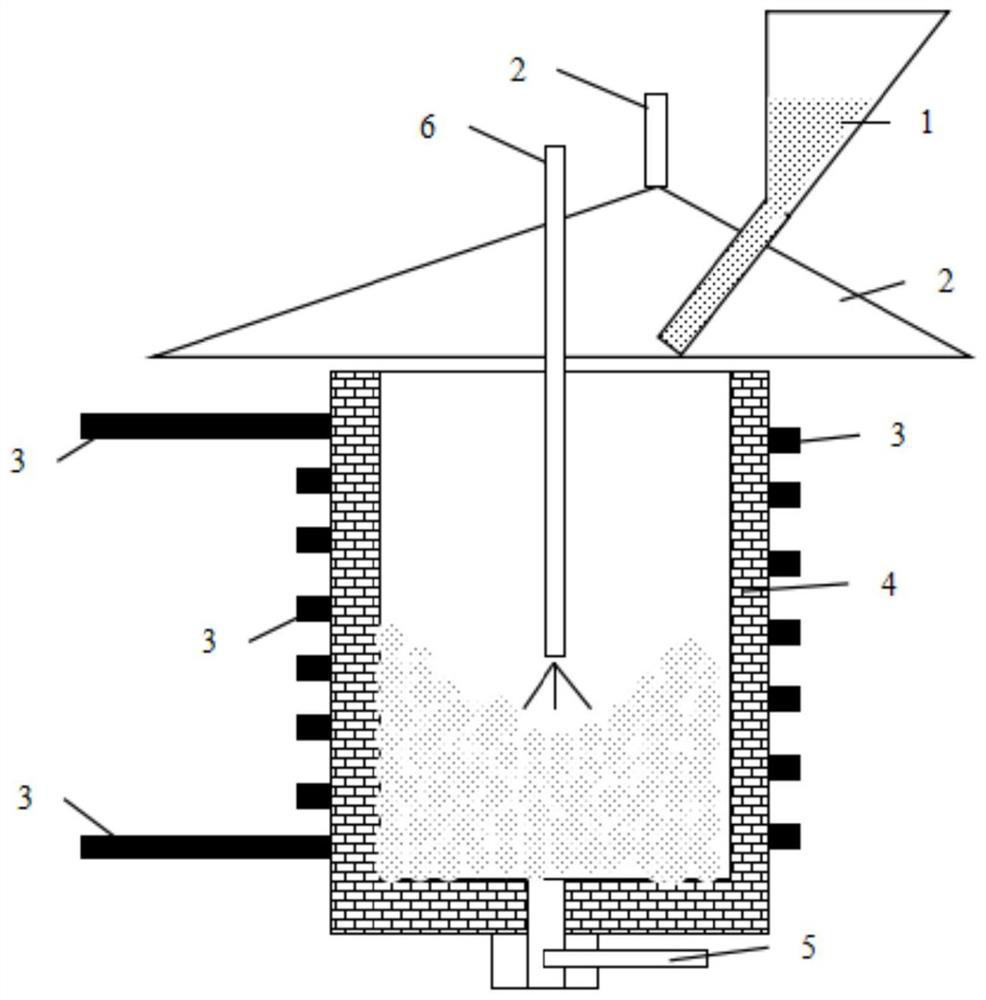

[0060] In step (2), specifically, the schematic diagram of the cross-sectional structure of the intermediate frequency induction converting furnace is as follows figure 2 As shown, the intermediate frequency induction converting furnace includes a feeding device 1, a dust collection device 2, an in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com